B

X

9

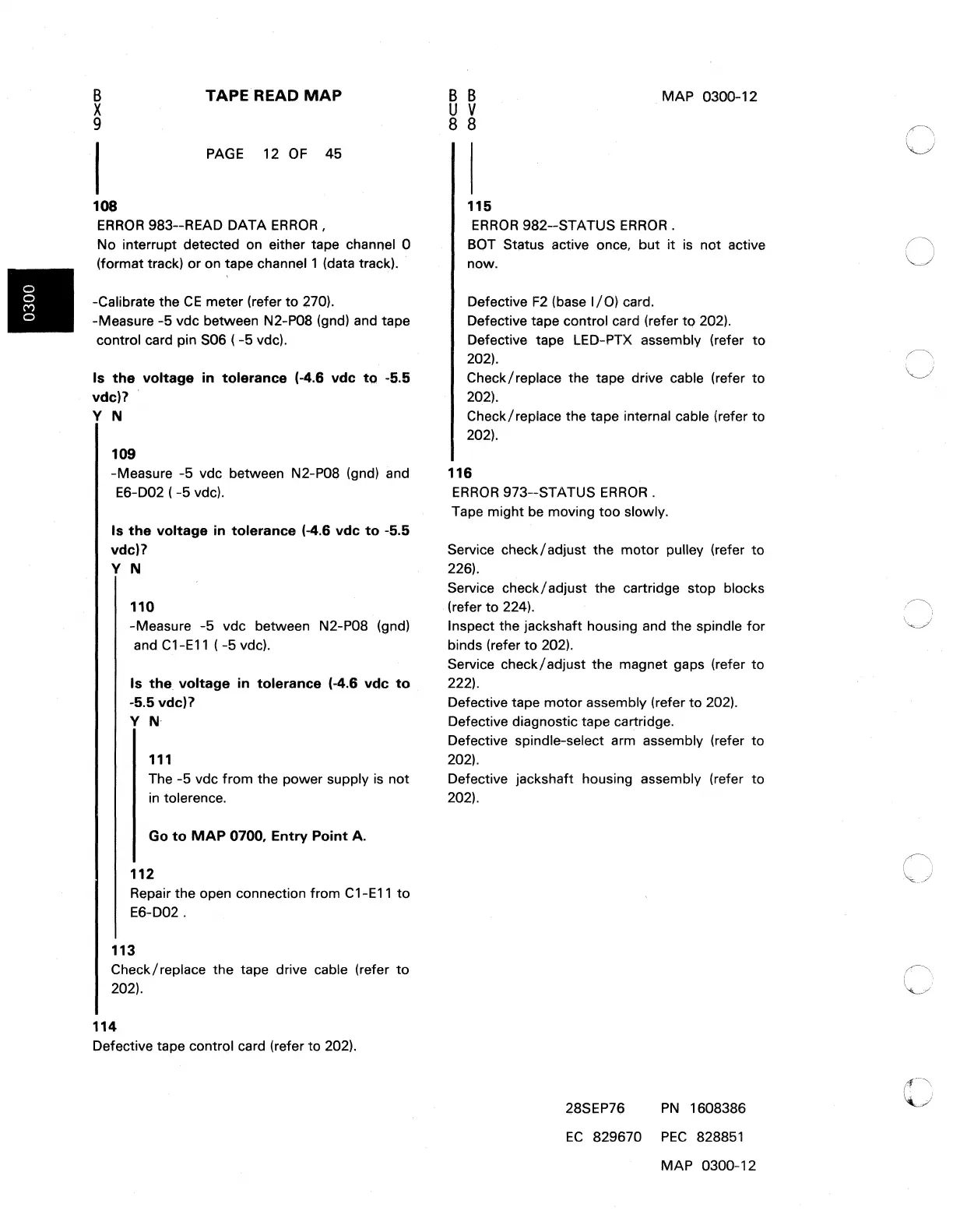

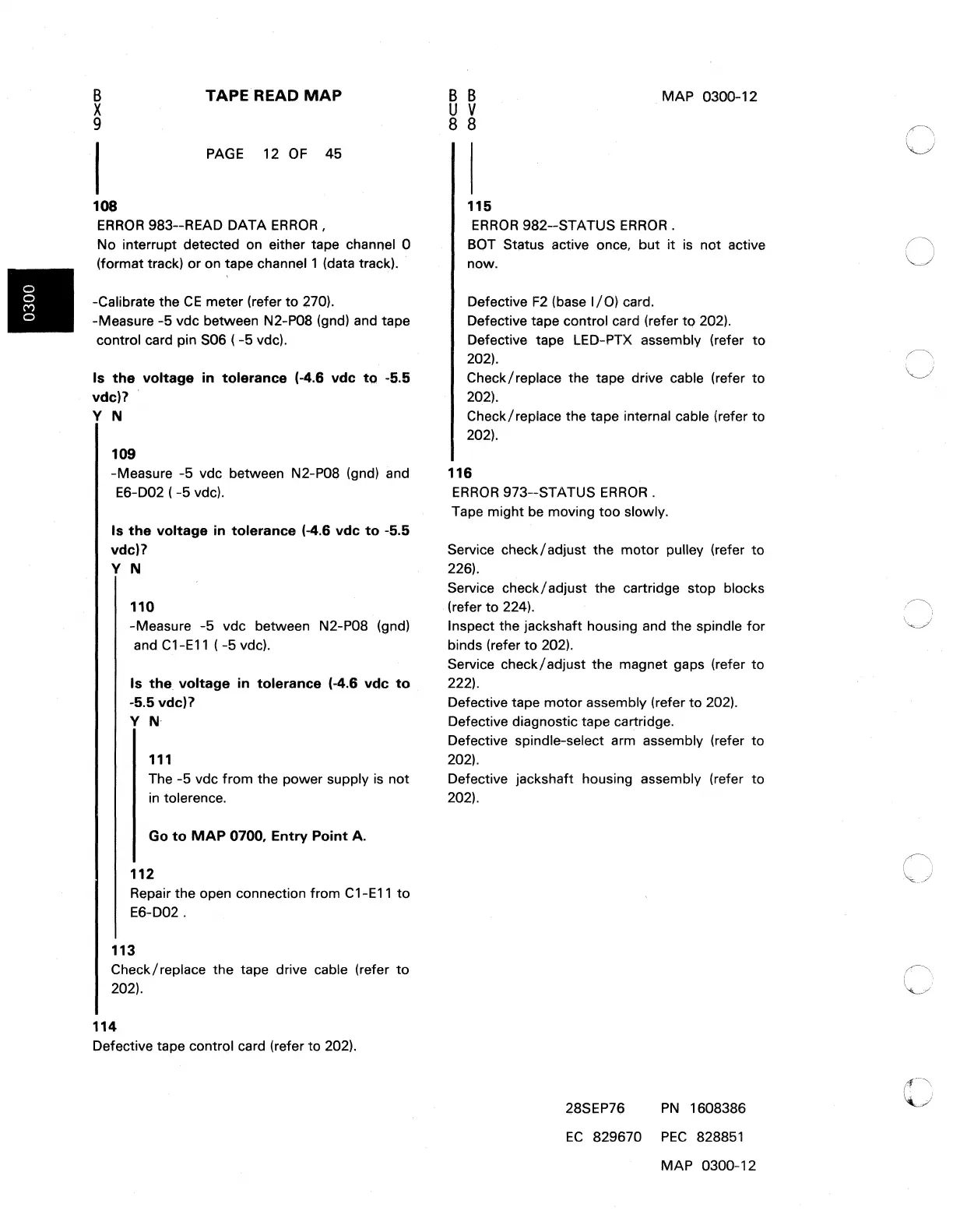

TAPE READ

MAP

PAGE

12

OF

45

108

ERROR

983--READ DATA ERROR,

No interrupt detected on either tape channel 0

(format track) or on tape channel 1 (data track).

-Calibrate the

CE

meter (refer

to

270).

-Measure

-5

vdc between N2-P08 (gnd) and tape

control card pin S06 (

-5

vdc).

Is

the

voltage

in

tolerance

(-4.6

vdc

to

-5.5

vdc)7 ,

Y N

109

-Measure

-5

vdc between

N2-POa

(gnd) and

E6-D02 (

-5

vdc).

Is

the

voltage

in

tolerance

(-4.6

vdc

to

-5.5

vdc)7

Y N

110

-Measure

-5

vdc between N2-P08 (gnd)

and

C1-E11

(-5

vdc).

Is

the,

voltage

in

tolerance

(.4.6

vdc

to

-5.5 vdc)?

Y

N-

111

The

-5

vdc from the power supply

is

not

in

tolerence.

Go

to

MAP

0700,

Entry

Point

A.

112

Repair the open connection from C1-E11

to

E6-D02.

113

Check/ replace the tape drive cable (refer

to

202).

114

Defective tape control card (refer

to

202).

B B

U V

8 8

115

MAP 0300-12

ERROR

982--STATUS ERROR.

BOT Status active once, but it

is

not active

now.

Defective

F2

(base

I/O)

card.

Defective tape control card (refer

tq

202).

Defective tape LED-PTX assembly (refer

to

202).

Check/replace the tape drive cable (refer

to

202).

Check/ replace the tape internal cable (refer

to

202).

116

ERROR

973--STATUS ERROR.

Tape might

be

moving too slowly.

Service check/adjust the motor pulley (refer

to

226).

Service check/adjust the cartridge stop blocks

(refer

to

224).

Inspect the jackshaft housing and the spindle

for

binds (refer

to

202).

Service check/adjust the magnet gaps (refer

to

222).

Defective tape motor assembly (refer

to

202).

Defective diagnostic tape cartridge.

Defective spindle-select arm assembly (refer

to

202).

Defective jackshaft housing assembly (refer

to

202).

28SEP76

PN

1608386

EC

829670

PEC

828851

MAP 0300-12

o

C)

Loading...

Loading...