o 0

F H

1 1

9 9

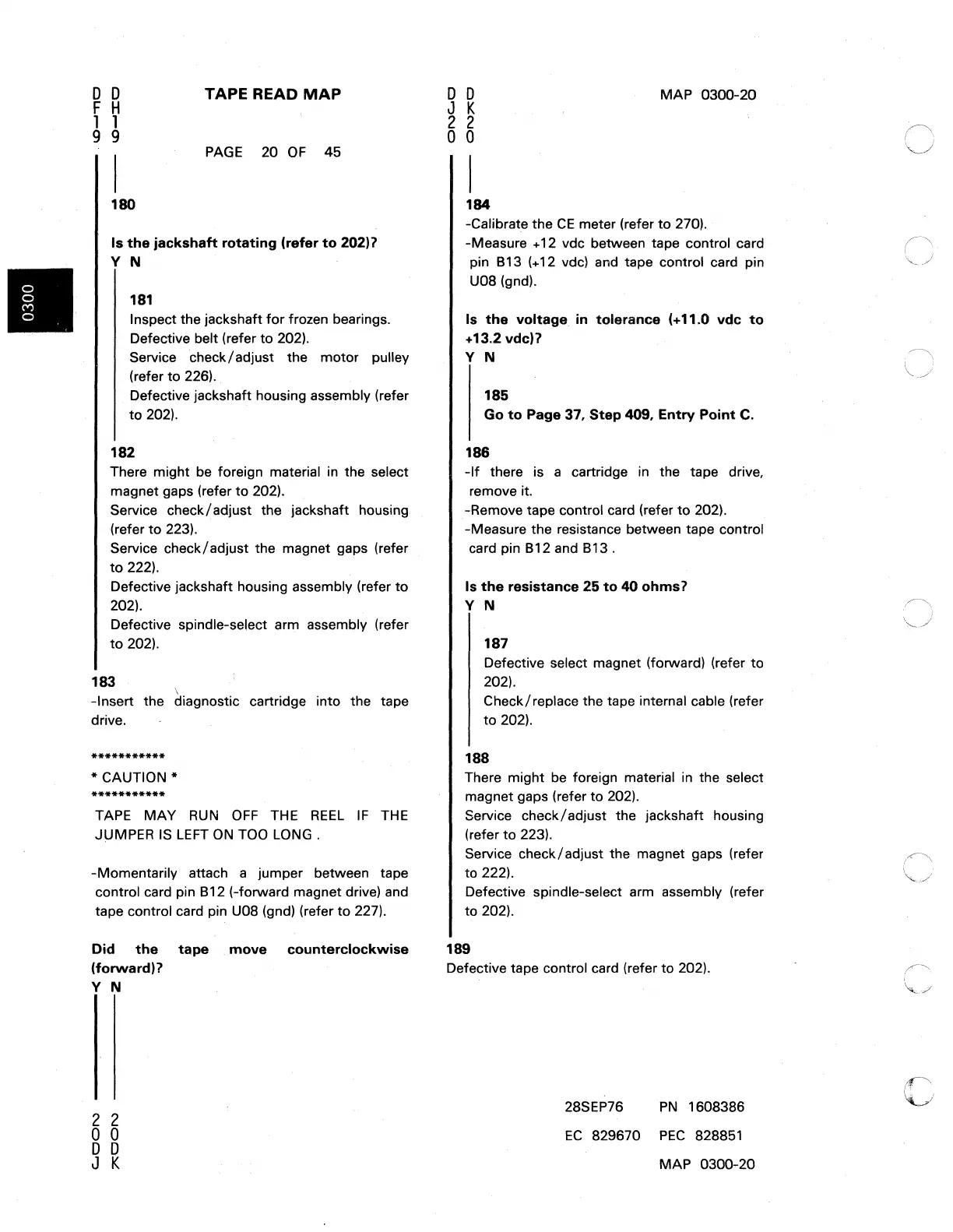

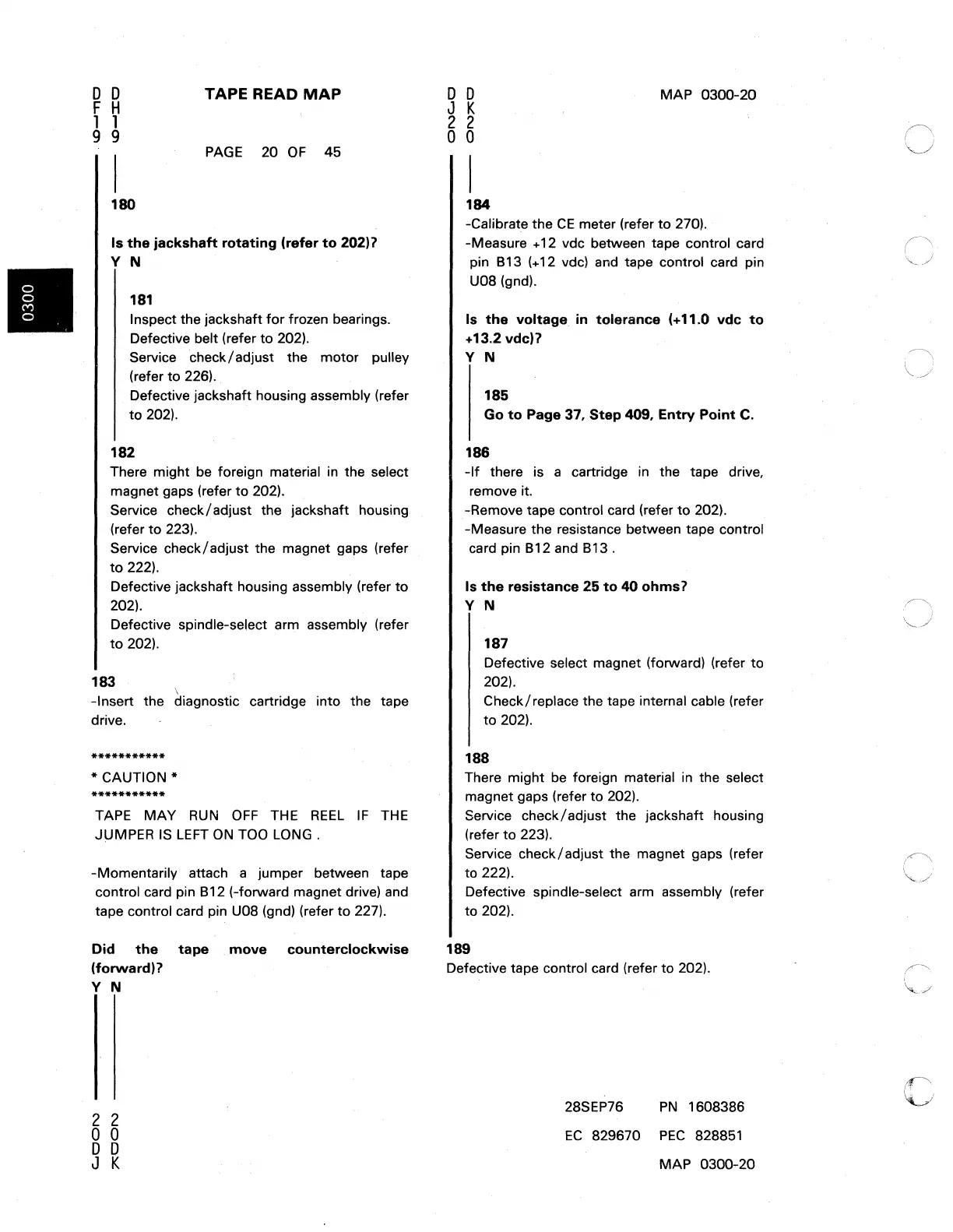

TAPE READ

MAP

PAGE

20

OF

45

180

Is

the

jackshaft

rotating

(refer

to

202)7

Y N

181

Inspect the jackshaft

for

frozen bearings.

Defective belt (refer

to

202).

Service check / adjust the motor pulley

(refer

to

226).

Defective jackshaft housing assembly (refer

to

202).

182

There might

be

foreign material

in

the select

magnet gaps (refer

to

202).

Service check/adjust the jackshaft housing

(refer

to

223).

Service check/adjust the magnet gaps (refer

to

222).

Defective jackshaft housing assembly (refer

to

202).

Defective spindle-select arm assembly (refer

to

202).

183

\

-Insert the diagnostic cartridge into the tape

drive.

***********

* CAUTION *

***********

TAPE MAY

RUN

OFF

THE

REEL

IF

THE

JUMPER IS

LEFT

ON

TOO

LONG.

-Momentarily attach a jumper between tape

control card pin 812 (-forward magnet drive) and

tape control card pin U08 (gnd) (refer

to

227).

Did

the

tape

move

counterclockwise

(forward)?

Y N

2 2

o 0

o D

J K

o 0

J K

2 2

o 0

184

MAP 0300-20

-Calibrate the

CE

meter (refer

to

270).

-Measure

+12

vdc between tape control card

pin 813

(+

12 vdc) and tape control card pin

U08 (gnd).

Is

the

voltage

in

tolerance

(+11.0

vdc

to

+13.2 vdc)?

Y N

185

Go

to

Page 37,

Step

409,

Entry

Point

C.

186

-If

there is a cartridge

in

the tape drive,

remove it.

-Remove tape control card (refer

to

202).

-Measure the resistance between tape control

card pin 812 and

813.

Is

the

resistance 25

to

40

ohms?

Y N

187

Defective select magnet (forward) (refer

to

202).

Check/ replace the tape internal cable (refer

to

202).

188

There might

be

foreign material

in

the select

magnet gaps (refer

to

202).

Service check/adjust the jackshaft housing

(refer

to

223).

Service check/adjust the magnet gaps (refer

to 222).

Defective spindle-select arm assembly (refer

to 202).

189

Defective tape control card (refer to 202).

28SEP76

PN

1608386

EC

829670

PEC

828851

MAP 0300-20

(\

I J

"'-_./

Loading...

Loading...