11Esprit - Installation and Servicing

GENERAL

General

1. The installation must comply with all relevant national and

local regulations.

2. The installation should be designed to work with flow

temperatures of up to 82

o

C.

3. All components of the system must be suitable for a working

pressure of 3 bar and temperature of 110

o

C. Extra care should

be taken in making all connections so that the risk of leakage

is minimised.

The following components are incorporated within the

appliance:

a. Circulating pump.

b. Safety valve, with a non-adjustable preset lift pressure of

3 bar.

c. Pressure gauge, covering a range of 0 to 6 bar.

d. An 8-litre expansion vessel, with an initial charge pressure

of 1.0 bar.

4. 'Make-up' Water. Provision must be made for replacing

water loss from the system, either :

a. From a manually filled 'make-up' vessel with a readily

visible water level. The vessel should be mounted at

least 150mm above the highest point of the system and

be connected through a non-return valve to the system,

fitted at least 150mm below the 'make-up' vessel on the

return side of the radiators.

Notes

a. The method of filling, refilling, topping up or flushing

sealed primary hot water circuits from the mains via a

temporary hose connection is only allowed if acceptable

to the local water authority.

b. Antifreeze fluid, corrosion and scale inhibitor fluids

suitable for use with boilers having aluminium heat

exchangers may be used in the central heating system.

Advice should be sought from a local water treatment

company.

BOILER CONTROL INTERLOCKS

Ideal Stelrad Group recommend that heating systems

utilising full thermostatic radiator valve control of temperature

in individual rooms should also be fitted with a room

thermostat controlling the temperature in a space served by

radiators not fitted with such a valve as stated in BS. 5449.

Central heating system controls should be installed to

ensure the boiler is switched off when there is no demand

for heating or hot water.

When thermostatic radiator valves are used, the space

heating temperature control over a living / dining area or

hallway having a heating requirement of at least 10% of the

boiler heat output should be achieved using a room

thermostat, whilst other rooms are individually controlled by

thermostatic radiator valves. However, if the system employs

thermostatic radiator valves on all radiators, or two port

valves without end switches, then a bypass circuit is

incorporated within the boiler to ensure a flow of water

should all valves be in the closed position.

ELECTRICAL SUPPLY

WARNING.

This appliance must be earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply. For IE reference should be made to

the current ETCI rules for electrical installations.

The point of connection to the mains should be readily

accessible and adjacent to the boiler.

N.B. THE FAN VOLTAGE IS 325VDC

CONDENSATE DRAIN Refer to Frames 21 & 49.

A condensate drain is provided on the boiler. This drain must

be connected to a drainage point on site. All pipework and

fittings in the condensate drainage system MUST be made of

plastic - no other materials may be used.

IMPORTANT.

Any external runs must be insulated.

The drain outlet on the boiler is standard 21.5mm (3/4”)

overflow pipe.

3

SYSTEM REQUIREMENTS - Central Heating

or

b. Where access to a 'make-up' vessel would be difficult,

by pre-pressurisation of the system.

The maximum cold water capacity of the system

should not exceed 143 litres, if not pressurized.

However, if the system is to be pressurized, the

efficiency of the expansion vessel will be reduced and

a larger vessel (or smaller system volume) may be

necessary. If the capacity of the vessel is not

considered sufficient for this, or for any other reason,

an additional vessel MUST be installed on the return

to the boiler.

Guidance on vessel sizing is given in Frame 3.

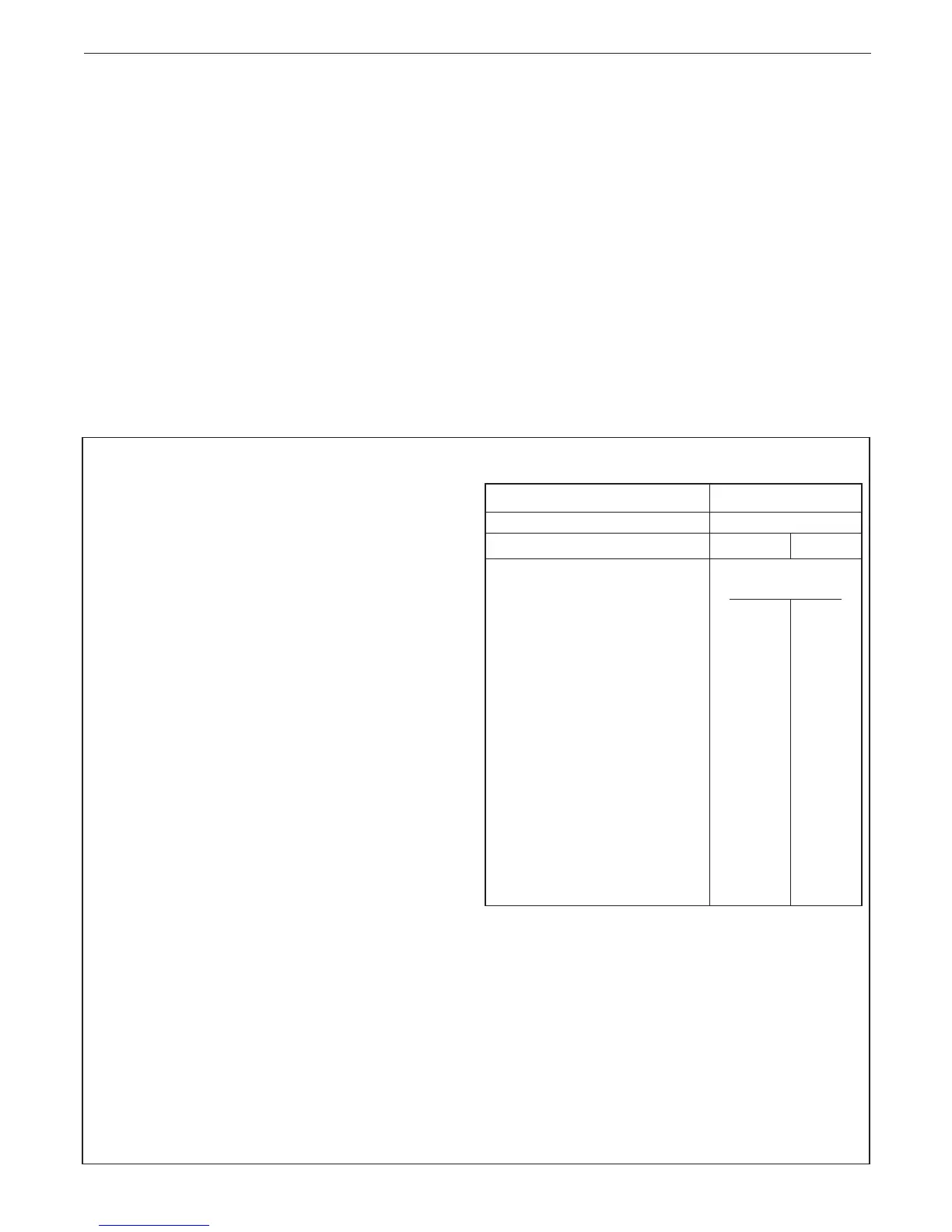

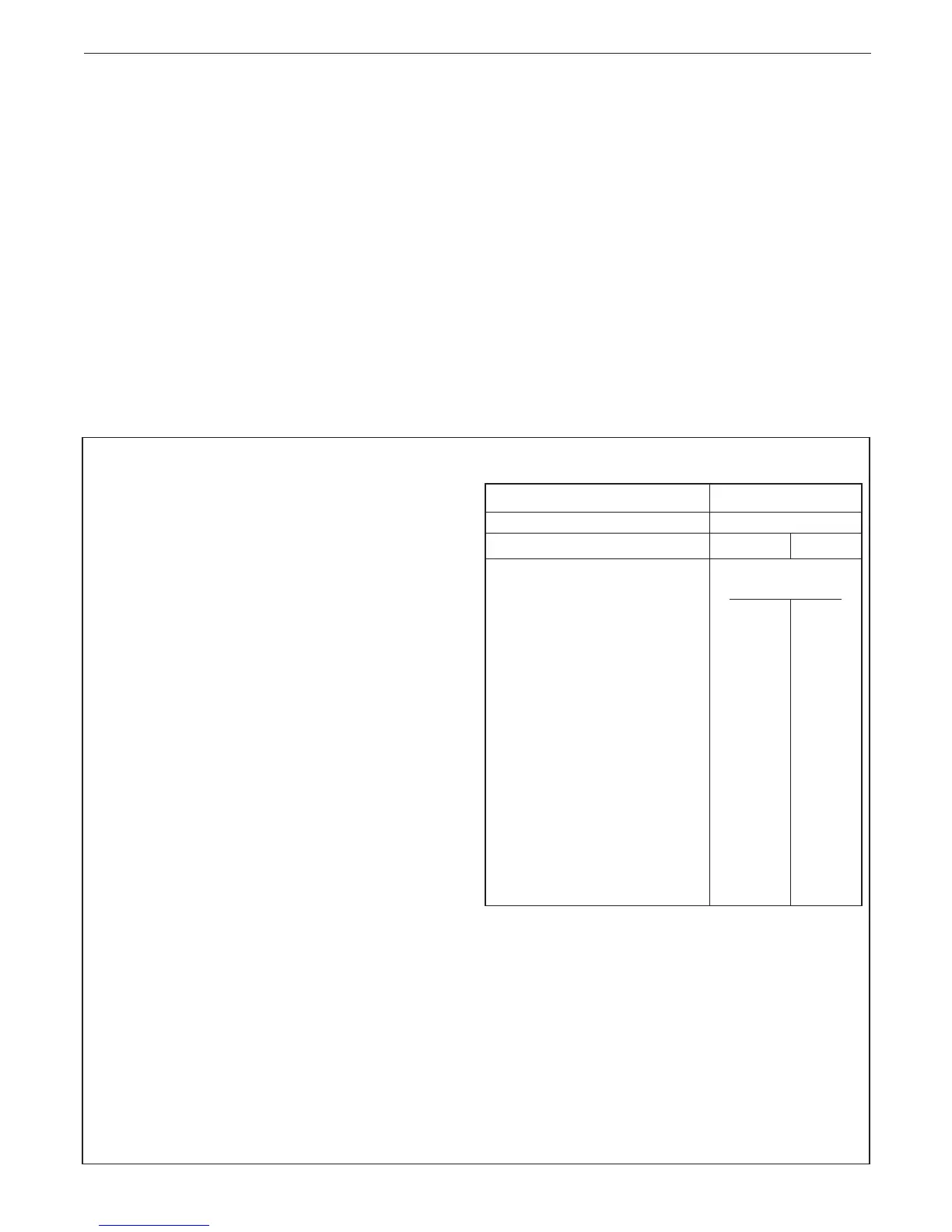

Safety valve setting bar 3.0

Vessel charge pressure bar 0.5 to 0.75

System pre-charge pressure bar None 1.0

System volume Expansion vessel

(litres) volume (litres)

25 1.6 1.8

50 3.1 3.7

75 4.7 5.5

100 6.3 7.4

125 7.8 9.2

150 9.4 11.0

175 10.9 12.9

190 11.9 14.0

200 12.5 14.7

250 15.6 18.4

300 18.8 22.1

For other system volumes

multiply by the factor across 0.063 0.074

Loading...

Loading...