Before accessing live electrical parts, disconnect the

power supply to the dryer using disconnect switch or

disconnect the cable connections.

Preventive maintenance

For optimum performance from your dryer, follow the

periodic maintenance schedule described below.

WEEKLY CONDENSATE DRAINS

Verify that the condensate drains

are operating correctly.

EVERY 4 MONTHS CONDENSER

Remove any dust from the con-

denser ns.

COMPRESSOR

Make sure compressor power

consumption complies with data

plate specications.

YEARLY CONDENSATE DRAINS

Completely disassemble the

drains and clean all their compo-

nents.

AIR FILTER

Replace air lter element.

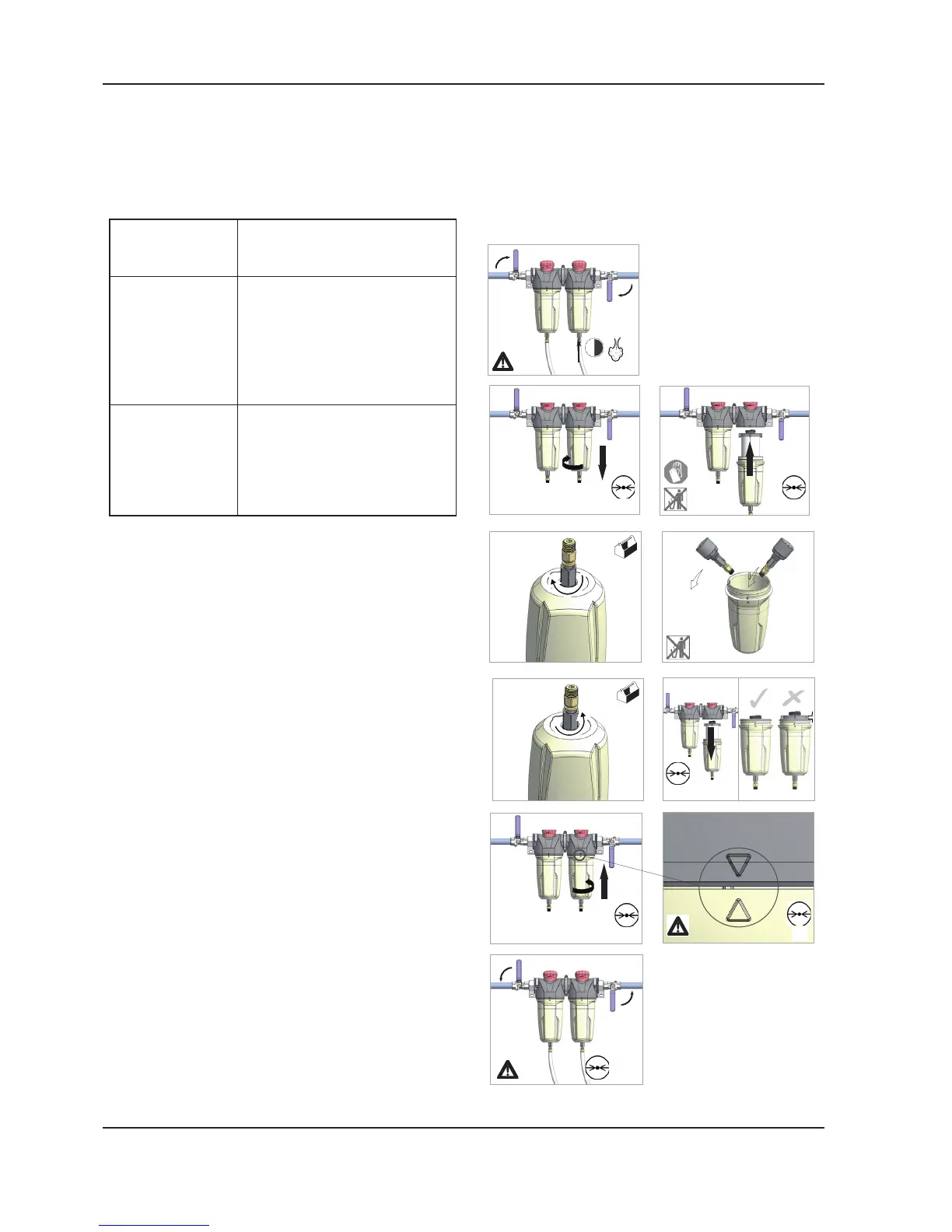

MOISTURE SEPARATOR MAINTENANCE

The moisture separator will operate indenitely under

normal working conditions, however at some time

it may be necessary to replace the seals should the

housing leak.

Isolate the housing from the air supply.

Fully depressurize in drain bowl as appropriate.

Unscrew bowl and remove. If pressure has not

been completely released from the housing,

air will escape from the warning hole giving

an audible alarm. Screw back bowl and repeat

instruction 2 before attempting again. Should

resistance to unscrewing be experienced,

provision is made for a ’C’ spanner to t onto the

ribs of the bowl.

Check condition of bowl seal and replace if

necessary. Clean screw threads.

Ret bowl with ’O’ ring seal.

Repressurize and check for leaks. If leaks occur

they will most probably be from the bowl ’O’

ring. Depressurize housing and remove ’O’ ring as

stated above and inspect and clean. Ensure that

mating surfaces are clean and then ret ’O’ ring

and repressurize.

1.

2.

3.

4.

5.

6.

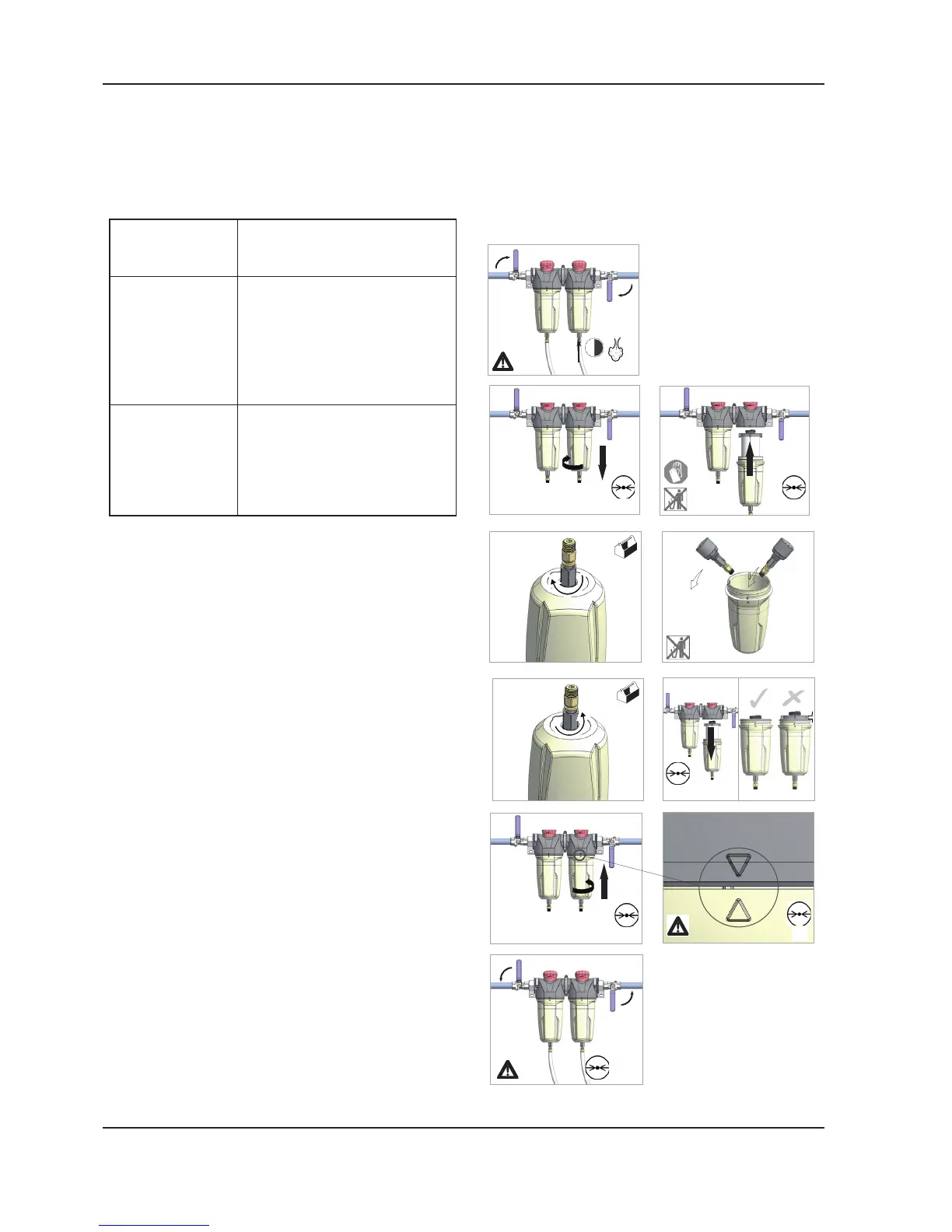

AIR FILTER MAINTENANCE

In order to ensure optimum compressed air quality the

lter element should be replaced as follows. (Used lter

elements must be disposed of in accordance with local

regulations.)

Use only genuine Ingersoll Rand replacement

elements.

Loading...

Loading...