http://air.ingersollrand.com 45

OPERATION AND MAINTENANCE MANUAL MAINTENANCE

DISASSEMBLING THE UNIT

The unit has been designed and constructed to

guarantee continuous operation.

The long service life of some components such as the

fan and compressor depends on good maintenance.

The unit must only be disassembled by a refrigerant

specialist.

Refrigerant liquid and lubricating oil inside the

refrigeration circuit must be recovered in compliance

with current norms in the country where the machine is

installed.

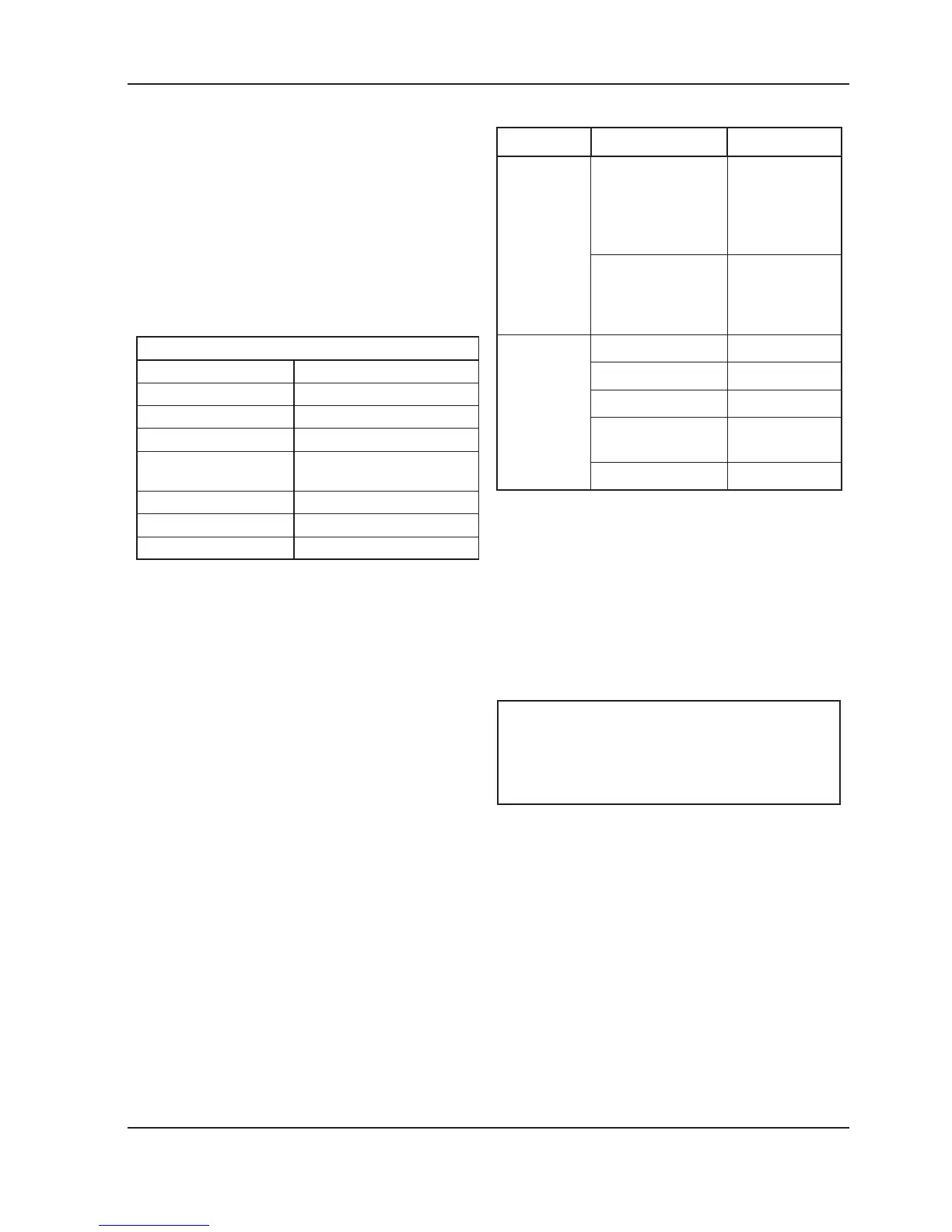

RECYCLING DISASSEMBLY

Frame and panels Steel / epoxy resin polyester

Heat exchanger (cooler) Stainless steel

Pipes Copper

Insulation Gum synthetic

Compressor Steel / copper / aluminium

/ oil

Condenser Aluminium

Refrigerant R134a

Valve Steel

REFRIGERANT LEAKS IN THE REFRIGERATION

CIRCUIT

The unit is despatched in perfect working order, already

charged.

Refrigerant leaks may be identied by tripping of the

refrigeration overload protector.

IF A LEAK IS DETECTED IN THE REFRIGERANT CIRCUIT,

SEEK TECHNICAL ASSISTANCE.

REFRIGERANT CHARGING

THIS OPERATION MUST ONLY BE PERFORMED BY A

REFRIGERANT SPECIALIST.

WHEN REPAIRING THE REFRIGERANT CIRCUIT,

COLLECT ALL THE REFRIGERANT IN A CONTAINER

AND DISPOSE OF IT IN THE APPROPRIATE MANNER.

CHARACTERISTICS OF REFRIGERANT R134A

In normal temperature and pressure conditions the

above refrigerant is a colorless, class A1/A1 gas with TVL

value of 1000 ppm (ASHRAE classication).

If a refrigerant leak occurs, thoroughly air the room

before commencing work.

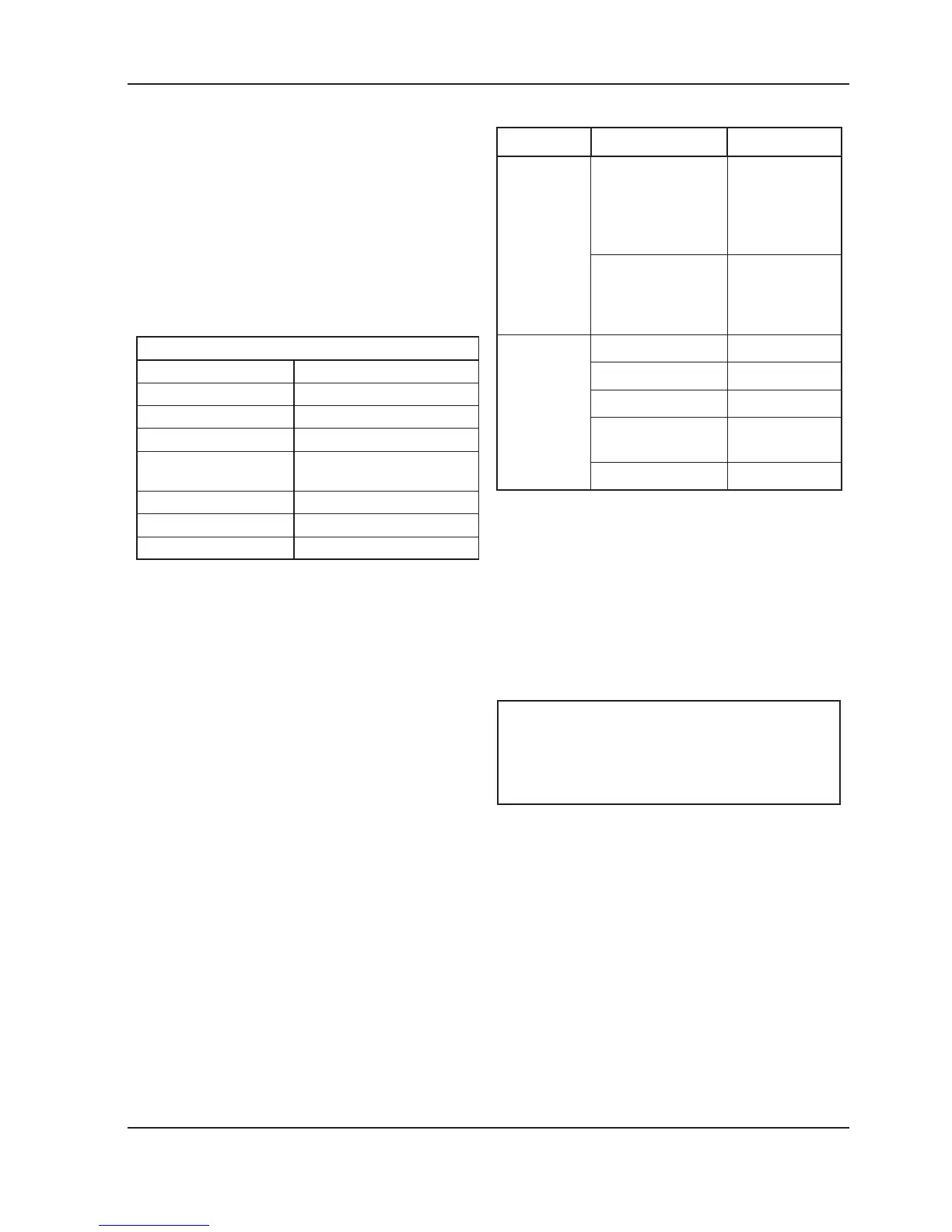

TROUBLESHOOTING

TROUBLE CAUSE ACTION

Solenoid

condensate

valve will

not close.

Debris in solenoid

valve prevents

diaphragm from

seating.

Remove

solenoid valve,

disassemble,

clean and

reassemble.

Short in electrical

component.

Check and

replace power

cord or timer as

needed.

Drain timer

will not

operate.

No electrical supply. Apply power.

Timer malfunction Replace timer.

Clogged port. Clean valve.

Solenoid valve

malfunction.

Replace

solenoid valve.

Clogged strainer. Clean strainer.

MAINTENANCE

Periodically clean the screen inside the valve to keep

the drain functioning at maximum capacity. To do this,

perform the following steps:

Close the strainer ball valve completely to isolate

it from the air receiver tank.

Press the TEST button on the timer to vent the

pressure remaining in the valve. Repeat until all

pressure is removed.

CAUTION

High pressure air can cause injury from

ying debris. Ensure the strainer ball valve is

completely closed and pressure is released from

the valve prior to cleaning.

3. Remove the plug from the strainer with a

suitable wrench. If you hear air escaping from

the cleaning port, STOP IMMEDIATELY and repeat

steps 1 and 2.

4. Remove the stainless steel lter screen and clean

it. Remove any debris that may be in the strainer

body before replacing the lter screen.

5. Replace plug and tighten with wrench.

6. When putting the Electric Drain Valve back into

service, press the TEST button to conrm proper

function.

1.

2.

Loading...

Loading...