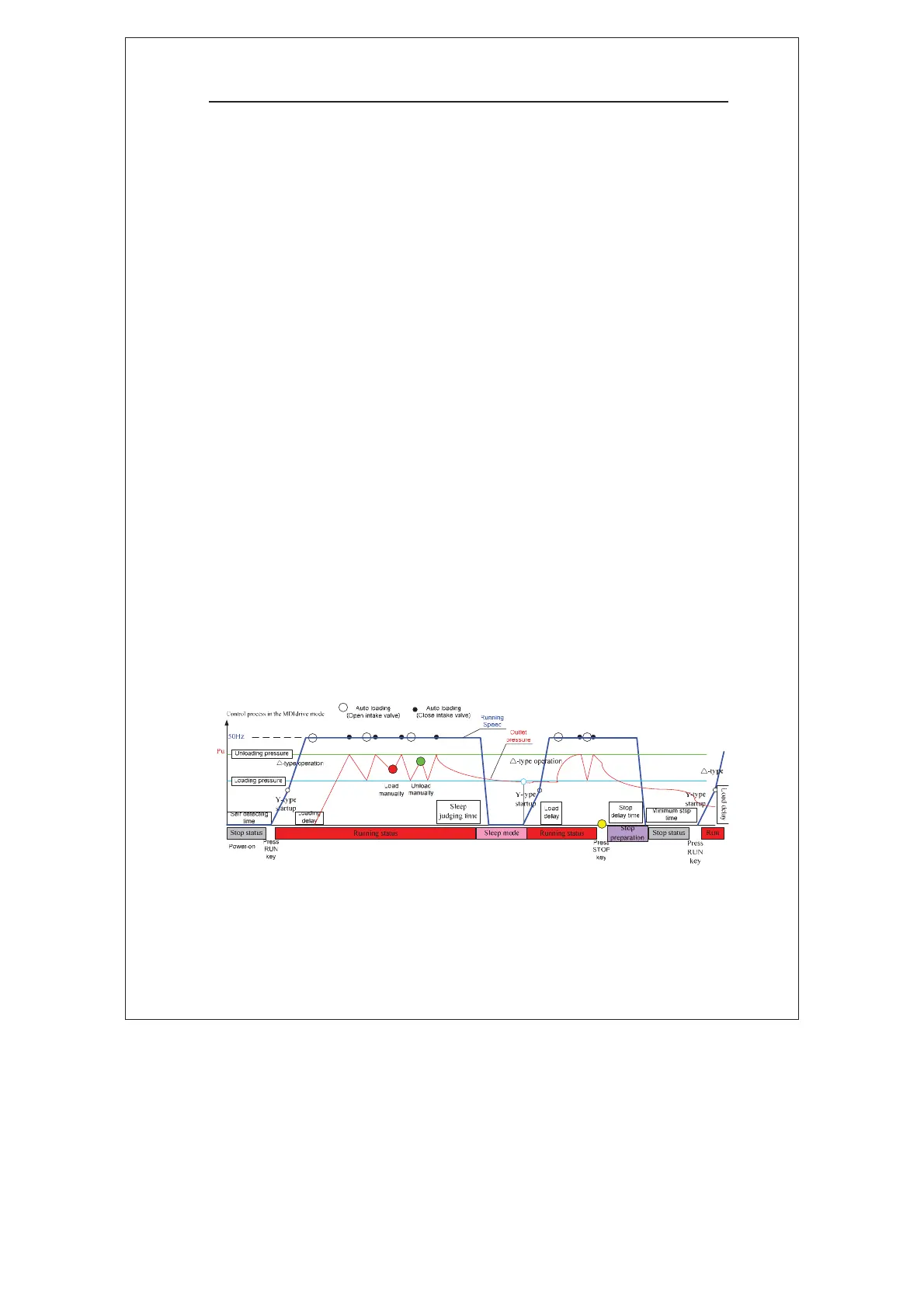

Figure 5-1 Control process in the MDI drive mode

After the MDI drives the main motor to run for 2 seconds, the controller

opens the open the intake valve and adjusts the air outlet pressure

through the PID operation.

In normal running status, once you press the “Stop” command key, the

controller will immediately turn off the solenoid valve to shut down the

intake valve and reduce the output frequency of the inverter to lower

limit of frequency, which makes the screw compressor continue to run

for some time at zero load condition (called “Preparation time for

stopping”) so as to let the screw compressor cool off before stopping

the inverter and turning off the fan.

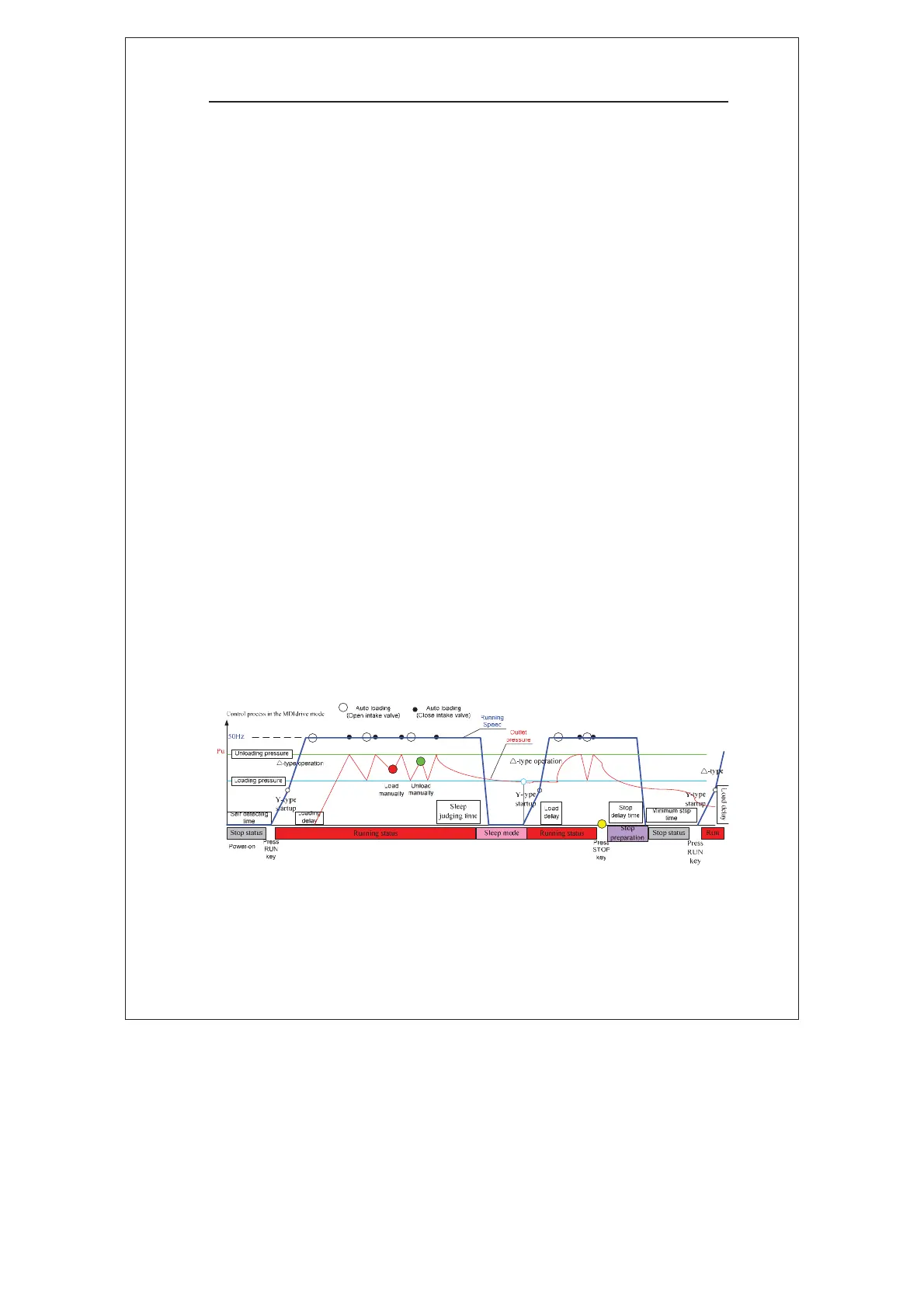

5.5.2 Control Process in the Power-line Drive Mode

In power-line drive mode, the controller detects the outlet pressure of

the screw compressor. Then it turns on or turns off the intake valve

based on the preset “Loading pressure” and “Unloading pressure” so as

to keep outlet pressure stable between the “Loading pressure” and

“Unloading pressure”.

When the air volume decreases, and the operating time at the

unloading status is shorter than the preset “Sleep mode judging time”,

the controller will stop the main motor and make the screw compressor

enter sleep mode (also called stopping mode), so as to save energy

and reduce equipment wearing.

The Control process in the power-line drive mode is shown as follows:

Figure 5-2 Control process in the MDI drive mode

efesotomasyon.com

Loading...

Loading...