Goodrive300-01A series VFD for air compressor Commissioning instruction

-25-

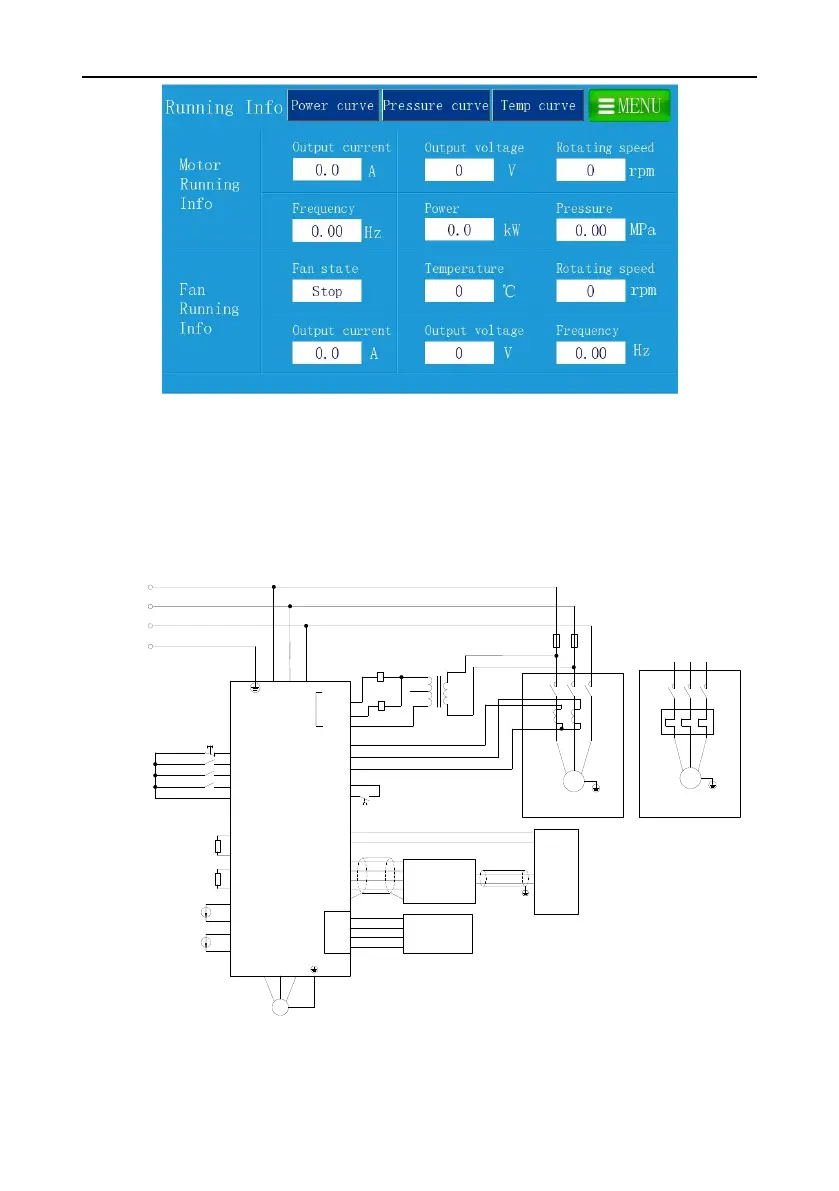

Figure 4-14 Running information interface

10. After adjusting user parameter, factory parameter and maintenance parameter according to the

touch screen manual, return to “workspace” interface and click “start” to run.

Note: All the parameters displayed in the interfaces in “4.1.2 Commissioning steps for dual-VFD air

compressor” are for reference only and subject to actual displayed content.

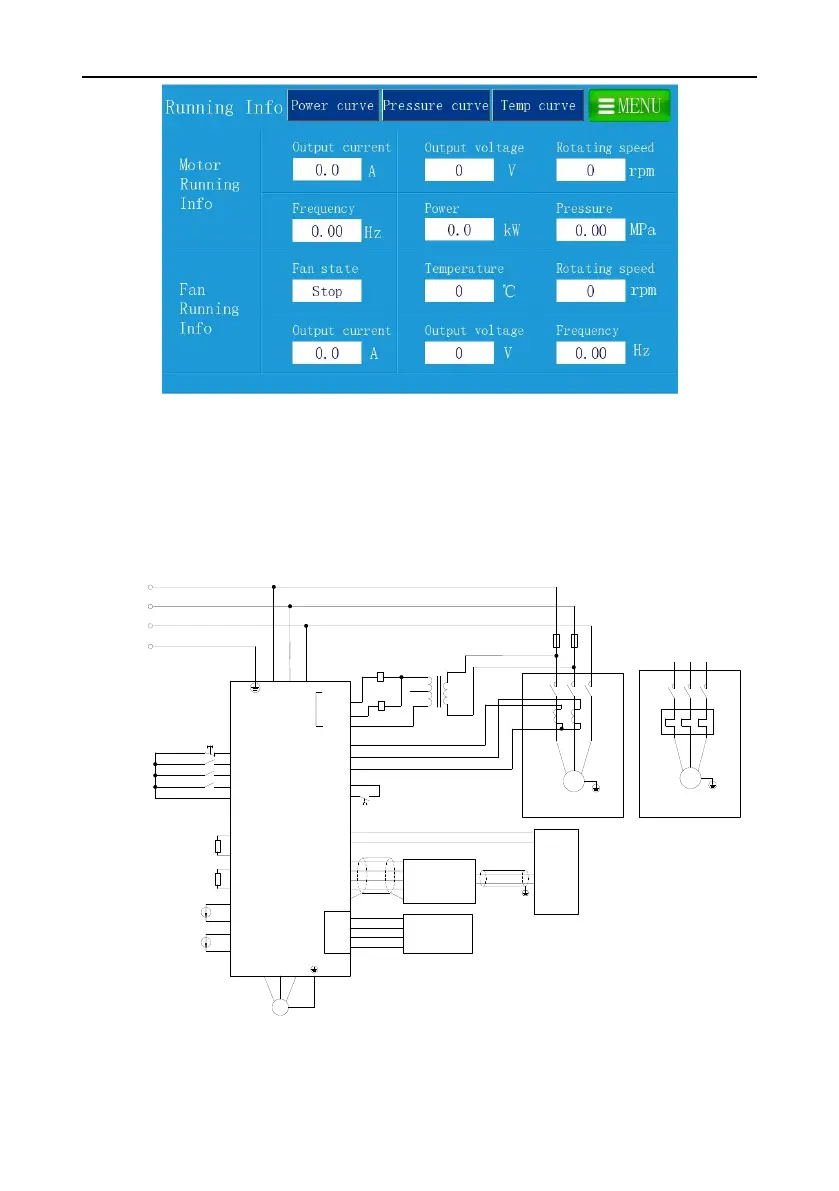

4.2 Commissioning guidance for single-VFD air compressor

4.2.1 Wiring diagram for single-VFD air compressor system

R

S

T

Master VFD

U V W

M

R

S

T

GD300-01A

PE

COM

COM

S5

S4

S3

S1

Emergency stop

PTB1

PTA1

P1-

P1+

P2-

P2+

RO1A

RO1C

RO2A

RO2C

Solenoid coil

220V

110V

0V

R

S

Low-frequency

transformer

M

Cooling fan

Adopt thermal relay to protect motor

overload

This is the backup plan

PT100

Discharge pressure

Auxiliary pressure

Contactor coil

Ib

Ic

Ia

PTB2

PTA2

PT100

Motor overtemperature

Oil gas temperature

Auxiliary temperature

M

Cooling fan

Adopt current transformer to

protect motor overload

KM

KM

S2

COM

FR

FR

Power detection

module

485+

485-

GND

+24V

CN10

485+

485-

GND

+24V

CGND/PE

485-

GND

+24V

485+

KM

Fan fault

Main motor

485-

485+

HMI

Wireless data

collection terminal

Figure 4-15 Wiring diagram for single-VFD air compressor system

Note: Pay attention to the dotted terminals during installing and wiring the current transformer,

Loading...

Loading...