Goodrive300-01A series VFD for air compressor Safety precautions

-3-

1.4.2 Commissioning and running

Disconnect all power supplies of the VFD before terminal wiring and wait for

at least the designated time after disconnecting the power supply.

High voltage is present inside the VFD during running. Do not carry out any

operation on the VFD except for keypad setting.

The VFD may start up by itself when P01.21=1. Do not get close to the VFD

and motor.

The VFD cannot be used as “Emergency-stop device”

The VFD cannot be used to brake the motor suddenly. A mechanical brake

device must be installed.

Note:

Do not switch on or off the input power supply of the VFD frequently.

For VFDs that have been stored for a long time, check and fix the capacitance and try pilot run

first before actual application.

Close the front cover before running the VFD; otherwise, electric shock may occur.

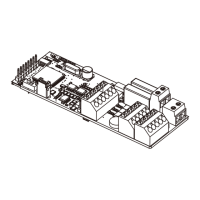

1.4.3 Maintenance and component replacement

Only well-trained and qualified professionals are allowed to carry out

maintenance, inspection, and component replacement of the VFD.

Disconnect all power supplies of the VFD before terminal wiring. Wait for at

least the time designated on the VFD after disconnecting the power supply.

Take proper measures to prevent screws, cables and other conductive

objects from falling into the VFD during maintenance and component

replacement.

Note:

Select proper torque to tighten the screws.

Keep the VFD and its parts and components away from combustible materials during

maintenance and component replacement.

Do not carry out any insulation voltage-endurance test on the VFD or measure the control circuit

of the VFD by megameter.

Take anti-static measures on internal parts during maintenance and component replacement.

1.4.4 Scrap treatment

There are heavy metals in the VFD. Treat with it as industrial effluent.

When the life cycle ends, the product should enter the recycling system. Dispose of

it separately at an appropriate collection point instead of placing it in the normal

waste stream.

Loading...

Loading...