Page 20

Page 21

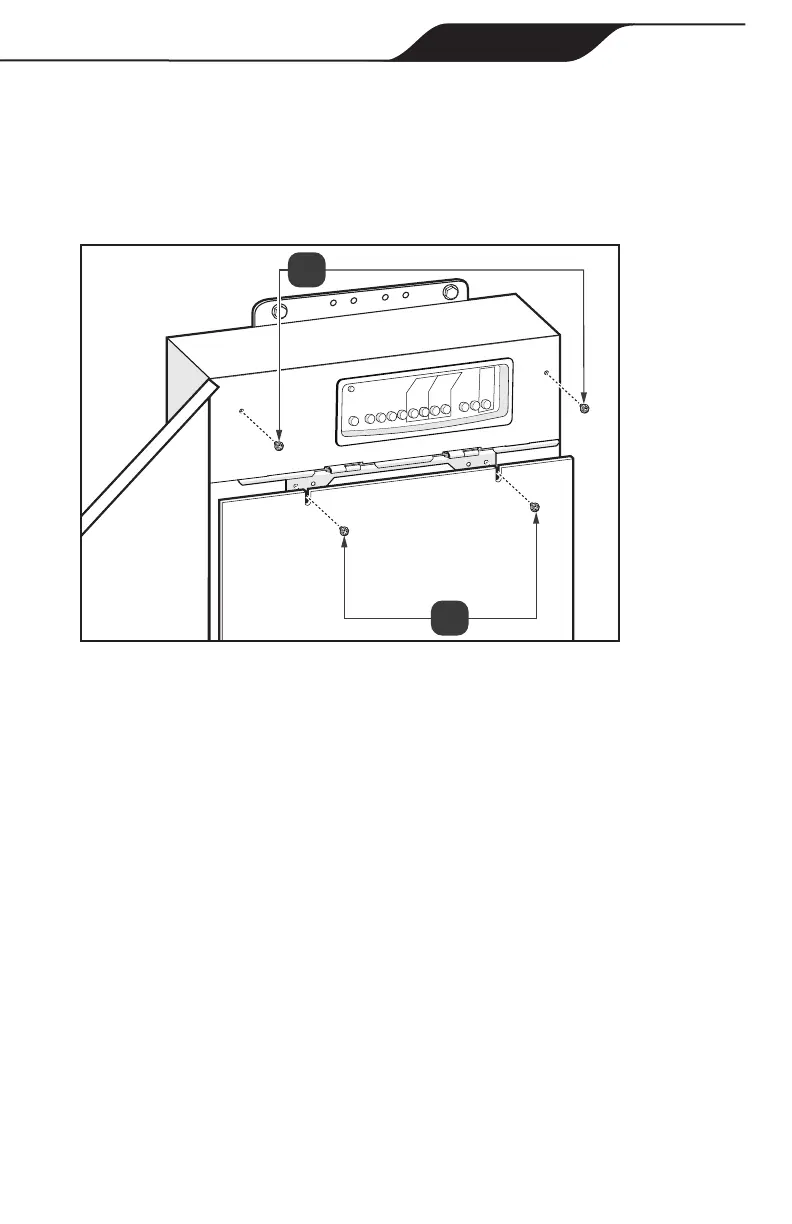

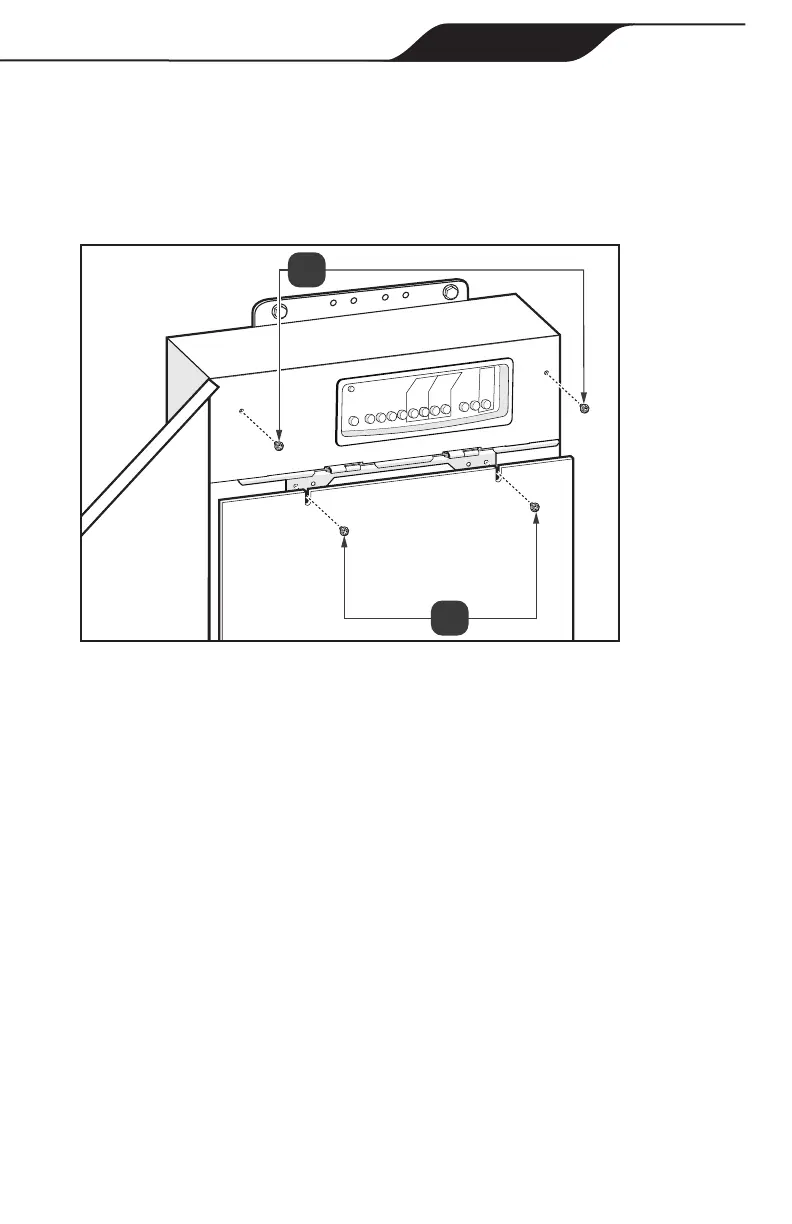

2. Secure AquaLink RS Conversion Kit cover with 2 screws, see Figure 17(a).

3. Align tabs on bottom of low voltage dead front to the slots in the power center

enclosure.

4. Secure the cover panel to the power center using the screws removed in

section 2.4, see Figure 17(b).

Figure 17. AquaLink

®

RS Conversion Kit Cover

5.8 Test the Equipment

Testing of the equipment is recommended before the automation system is put

into service.

1. Use the multimeter to check continuity to ground for all metal parts.

2. Put the system into Service mode.

3. While in Service mode each auxiliary can be toggled to ensure that the

equipment is functioning and that it is connected to the correctly labeled AUX

on the PIB.

4. Ensure all enclosure openings are closed and sealed for water ingress

protection.

Section 6. Program DIP Switch Settings

Two sets of DIP switches (S1 and S2) exist to control system conguration. The

DIP switches are monitored constantly by the system and if they are changed it is

immediately recognized. Restarting the system is recommended to ensure all of the

settings get updated.

Installation & Operation Manual

Loading...

Loading...