12 - 8

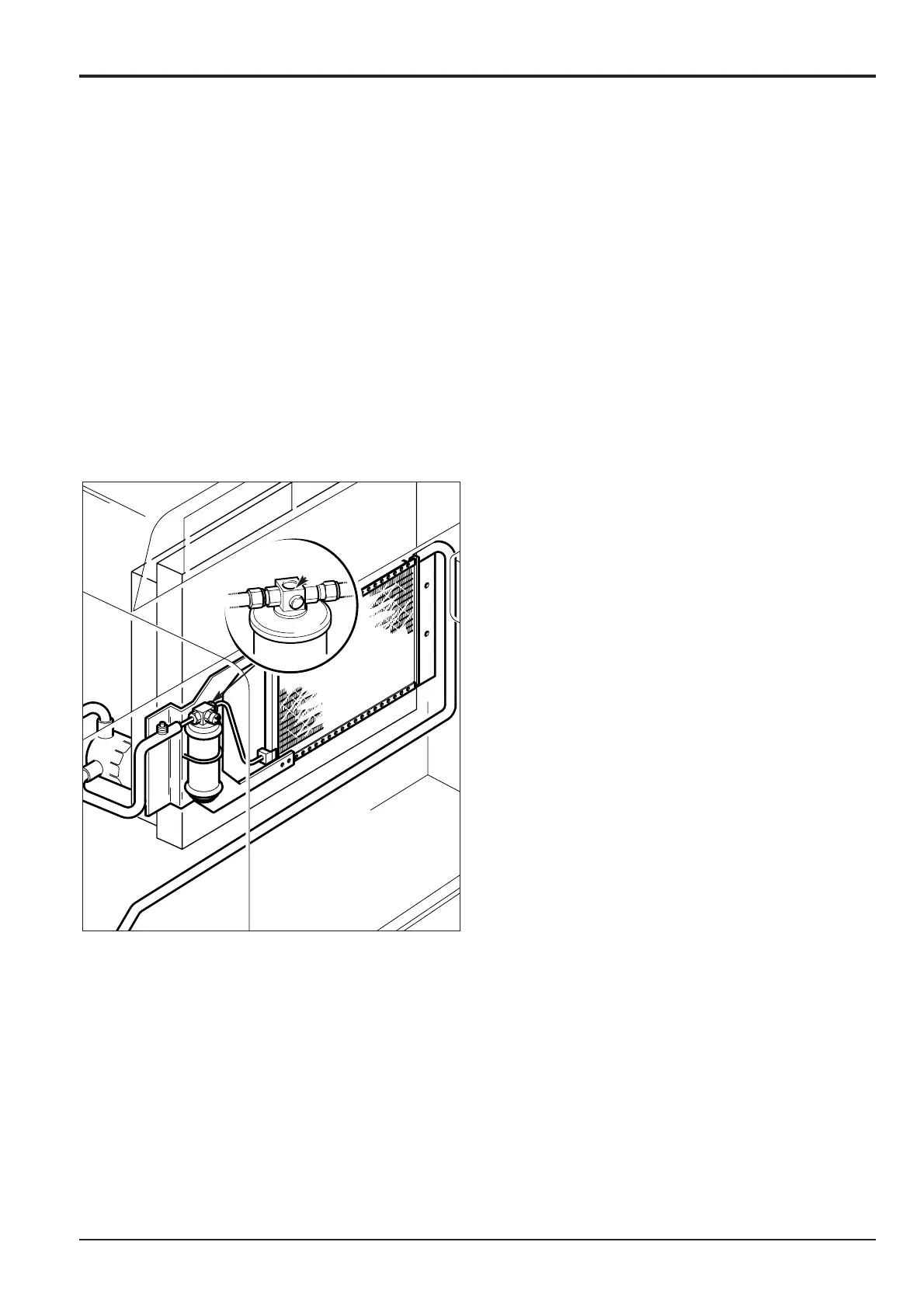

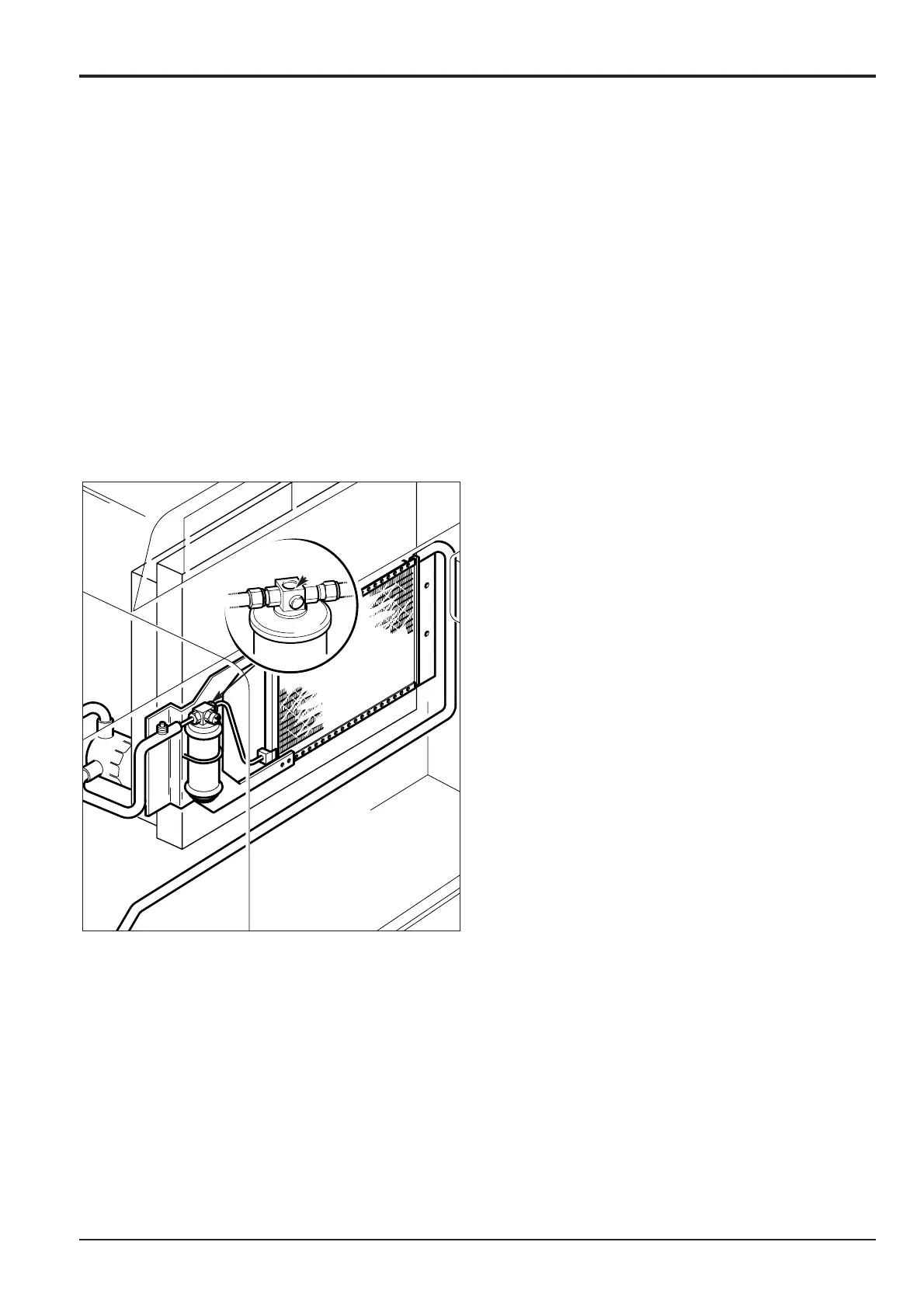

Checking Refrigerant Charge Level

The pressure in the system, i.e. the refrigerant charge level

can be determined by checking the state of refrigerant at the

receiver drier sight glass. The receiver drier is mounted on

the radiator on the side of the engine.

If the level of charge is correct the sight glass will be clear. If

the charge is low bubbles will be seen. Bubbles may also be

an indication of inadequate cooling, due to a restriction of air

flow around the condenser coil. Recharging of the system

should be carried out by an air conditioning engineer. Check

refrigerant charge level as follows:

1 Park the machine on firm, level ground. Lower the

excavator arms to the ground. Engage the parking

brake.

2 Open the left hand side, rear door.

3 Start the engine and run at idle. Switch air conditioning

ON to circulate refrigerant.

4 Check refrigerant charge level at sight glass A.

Leak Testing

! WARNING

Leak testing in Air Conditioning systems should be

carried out only in a well ventilated area.

BF 1-2

Note: The refrigerant is heavier than air and will leak

downwards from the defective component. Check in still

conditions but in a well ventilated area.

Hose or pipe connections are likely leakage points of any

refrigerant circuit.

To test for leaks in the high pressure side of the system i.e.

from the compressor output to the expansion valve, run the

air conditioning for a few minutes then switch off the engine

and test for leakage using an electronic leak detector or

soapy water.

To test for leakage in the low pressure side of the system,

switch off the air conditioning and leave for a few minutes

before testing.

Tightening Leaking Hoses

! WARNING

The air conditioning system is a closed loop system and

contains pressurised refrigerant. No part of the system

must be disconnected except by a qualified refrigeration

engineer. You can be severely frostbitten or injured by

escaping refrigerant

4-3-4-1/1

The refrigerant hoses have crimped ferrule end fittings. The

hose connectors have an 'O' ring seal which compresses

when the connection is tight, creating an air tight seal.

Hoses are used to connect the inlets and outlets of the

compressor, condenser, receiver drier and expansion valve

(the evaporator coil is connected to the expansion valve

within the air conditioning unit using rigid pipes).

If leakage is detected from a hose connector, either by

means of an electronic leak detector or soapy water, tighten

the connector up and repeat the leakage test. If leakage is

still evident, it will be necessary to de-gas the system and

renew the connector 'O' ring seal.

Section B

Body & Framework

9803/6400

Section B

12 - 8

Issue 1

Air Conditioning

AA

Loading...

Loading...