6 - 2

Checking the Slew Gearbox Oil Level

1. Prepare the Machine

Position the machine on level ground. Stop the engine

and remove the starter key.

2. Locate the Slew Gearbox

See Component Location Diagrams at the end of this

section.

3. Check the Level

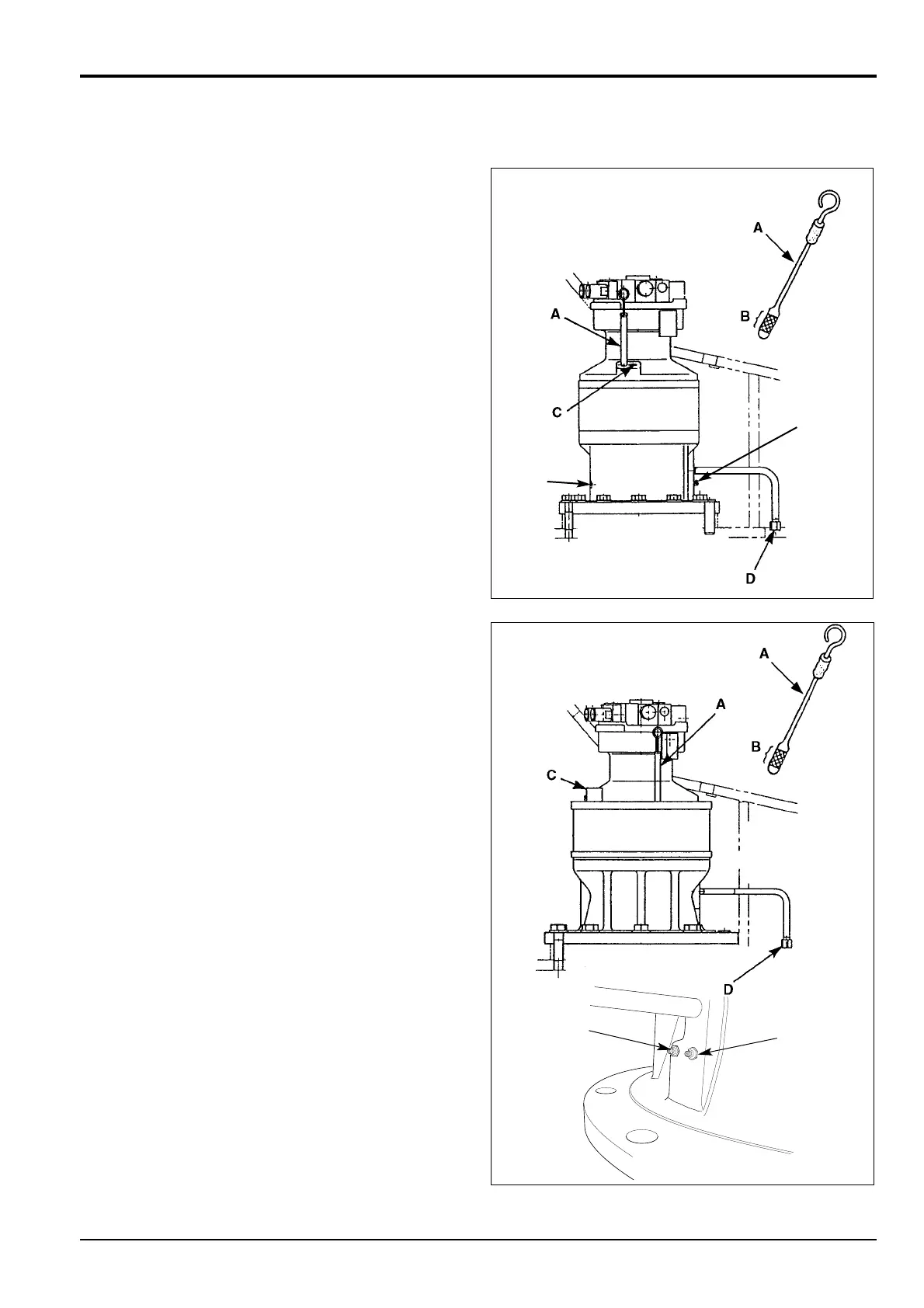

a. Remove the dipstick A, wipe it clean and re-fit.

b. Remove the dipstick again and check that the oil

level is within the range B.

c. If necessary, top up through filler port C. (See

Lubricants and Capacities for oil type).

4. Refit the Dipstick.

Changing the Slew Gearbox Oil

1. Prepare the Machine

Position the machine on level ground. Stop the engine

and remove the starter key.

2. Drain the Oil

a. Remove the drain plug D. Allow the oil to drain out.

b. Wipe the drain plug clean. Remove any metallic

particles, if foreign matter is found, contact local

dealer.

c. Refit the drain plug. Make sure it is tight.

3. Fill with New Oil

See Lubricants and Capacities for oil type and volume.

Fill with new oil through filler port C until it reaches the

full mark on the dipstick when settled. refit the dipstick.

4. Check for Leaks

Run the machine, operate the slew controls and make

sure there are no leaks.

Replenishing Slew Gearbox Grease

1. Prepare the Machine

Position the machine on level ground. Stop the engine

and remove the starter key.

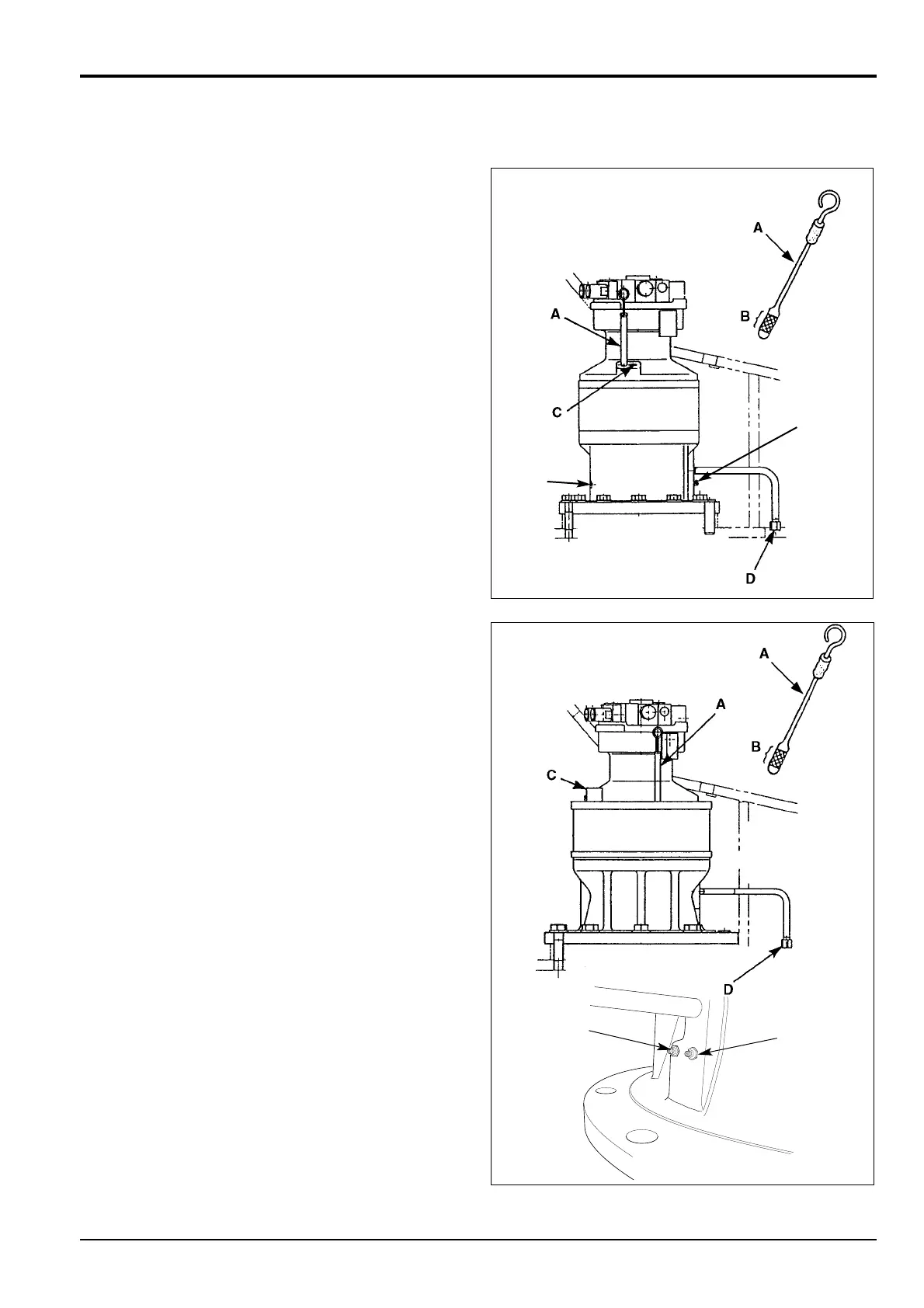

2. Remove Air Bleed Plug E.

!!

CAUTION

Failure to remove the bleed plug before adding grease

could damage the inner seal.

8-3-4-7

3. Fill Up with Grease

See Lubricants and Capacities for grease type.

Pump in grease through nipple F until the grease starts

to ooze from bleed plug E. Refit and tighten the bleed

plug.

On later machines, the slew gearbox bearing (normally

lubricated at point F has changed to a sealed for life type

bearing and no longer requires lubrication.

Note: All machines that have a grease nipple at F still require

lubricating every 1000 hours.

Section 3

Routine Maintenance

9803/6400

Section 3

6 - 2

Issue 2*

Transmission (continued)

*JS200/JS210/JS220

*JS240/JS260

E

F

*

F

E

Loading...

Loading...