7 - 2

Checking/Adjusting the Track Tension

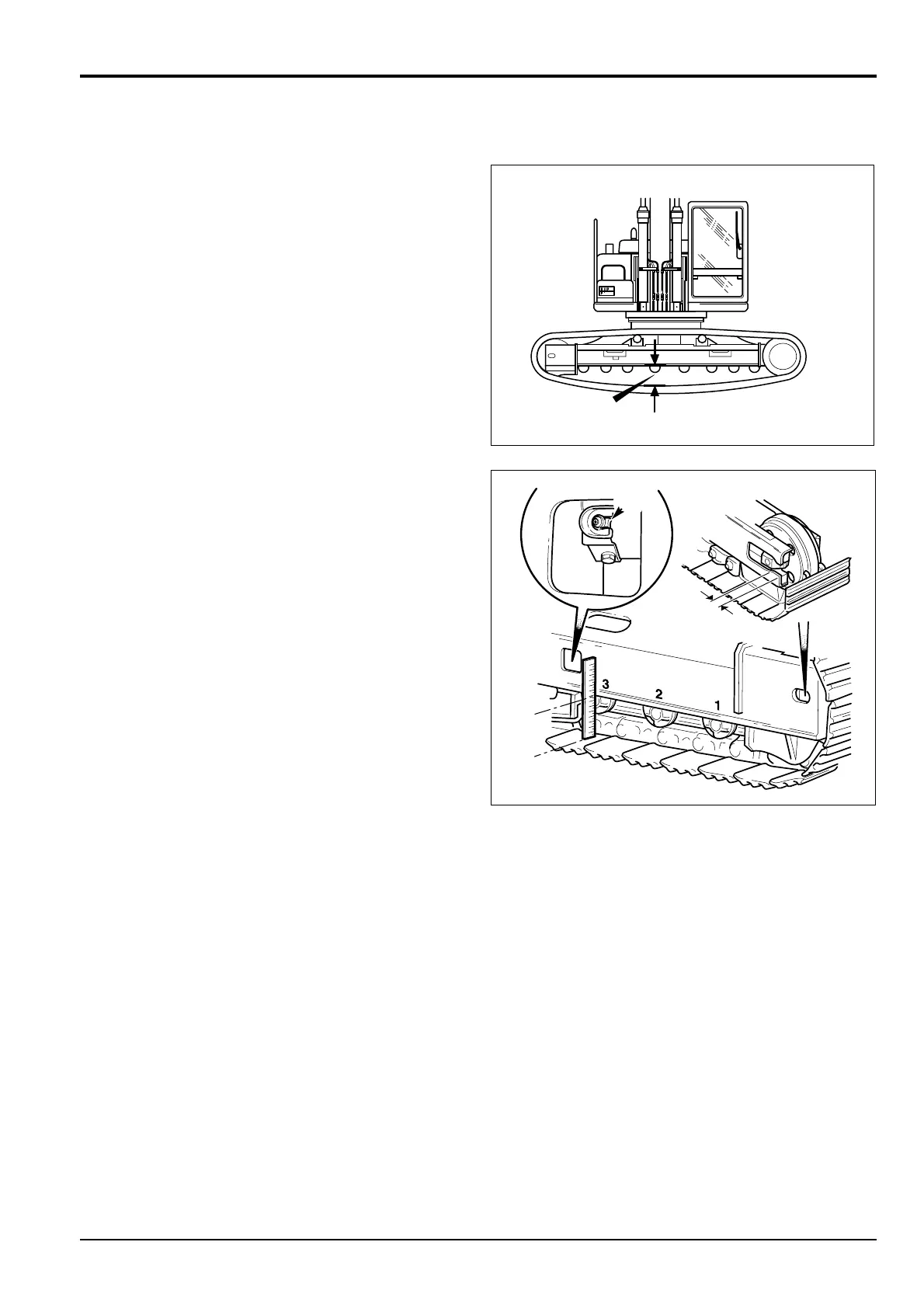

1. Prepare the Machine

Position the machine on level ground. Run it backwards

and forwards several times. Stop after running it

forwards.

Carry out steps 1 to 3 of Cleaning the Tracks. Block up

the undercarriage frame. Finish track rotation by running

the track forwards. Stop the engine and remove the

starter key.

!!

WARNING

NEVER position yourself or any part of your body under a

raised machine which is not properly supported. If the

machine moves unexpectedly you could become

trapped and suffer serious injury or be killed.

INT-3-3-7

2. Check the Tension

Measure gap A in line with the fourth roller from the front

and between the lower surface of the track frame and

the upper surface of the shoe. The dimension should be

275-295 mm for hard ground conditions. For operation

on soft sand or sticky mud it should be 320-340 mm.

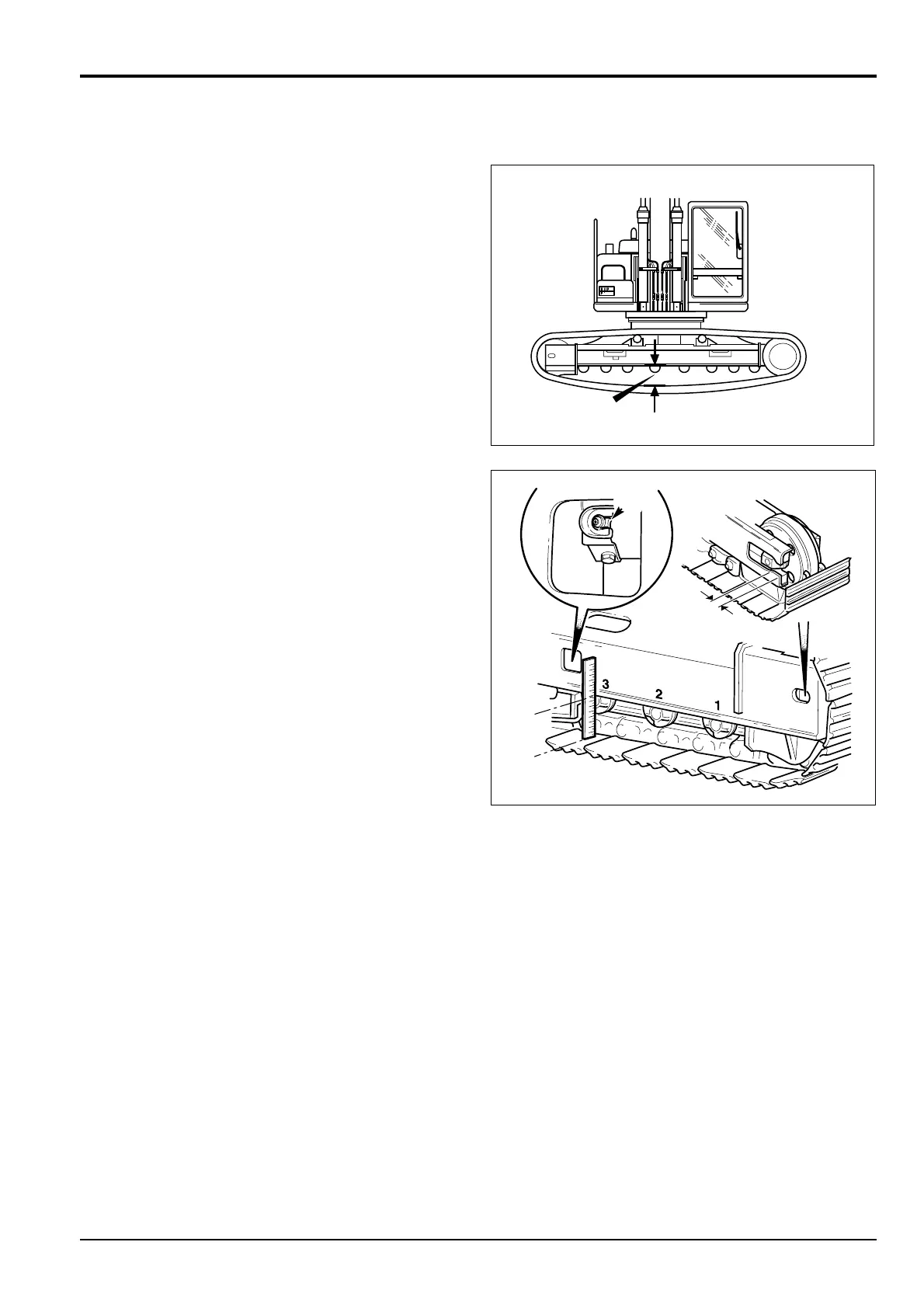

3. Adjust the Track Tension

Adjustment is made by either injecting or releasing

grease from the check valve B. Inject grease to reduce

the gap (increase the tension) or open to release grease

and increase the gap.

!!

WARNING

When opening the check valve always stand to one side

and loosen a little at a time until grease starts to come

out. If you over-loosen too much grease could spurt out

or the valve cover fly out and cause serious injury.

8-3-4-5

!!

WARNING

Under no circumstances must the check valve be

dismantled or any attempt made to remove the grease

nipple from the check valve.

8-3-4-9

If gap C exists between the idler wheel shaft and the

track frame, you may use pressure to apply the grease. If

there is no gap C after the application of grease, then the

necessary repairs must be carried out.

Note: Excessive tension can cause the track rail to wear the

drive rollers and sprocket, insufficient tension can cause

wear to the drive sprocket and track rail.

4. Lower the Track

Remove the blocks from beneath the undercarriage and

lower the track to the ground using the boom and dipper

controls.

5. Repeat for the Opposite Track

Slew the boom round to the other side and repeat steps

1 to 4 above.

Section 3

Routine Maintenance

9803/6400

Section 3

7 - 2

Issue 3*

Tracks and Running Gear (continued)

Loading...

Loading...