−11−

(4)針とかまのタイミング/Needle-to-hook timing/機針和旋梭的同步

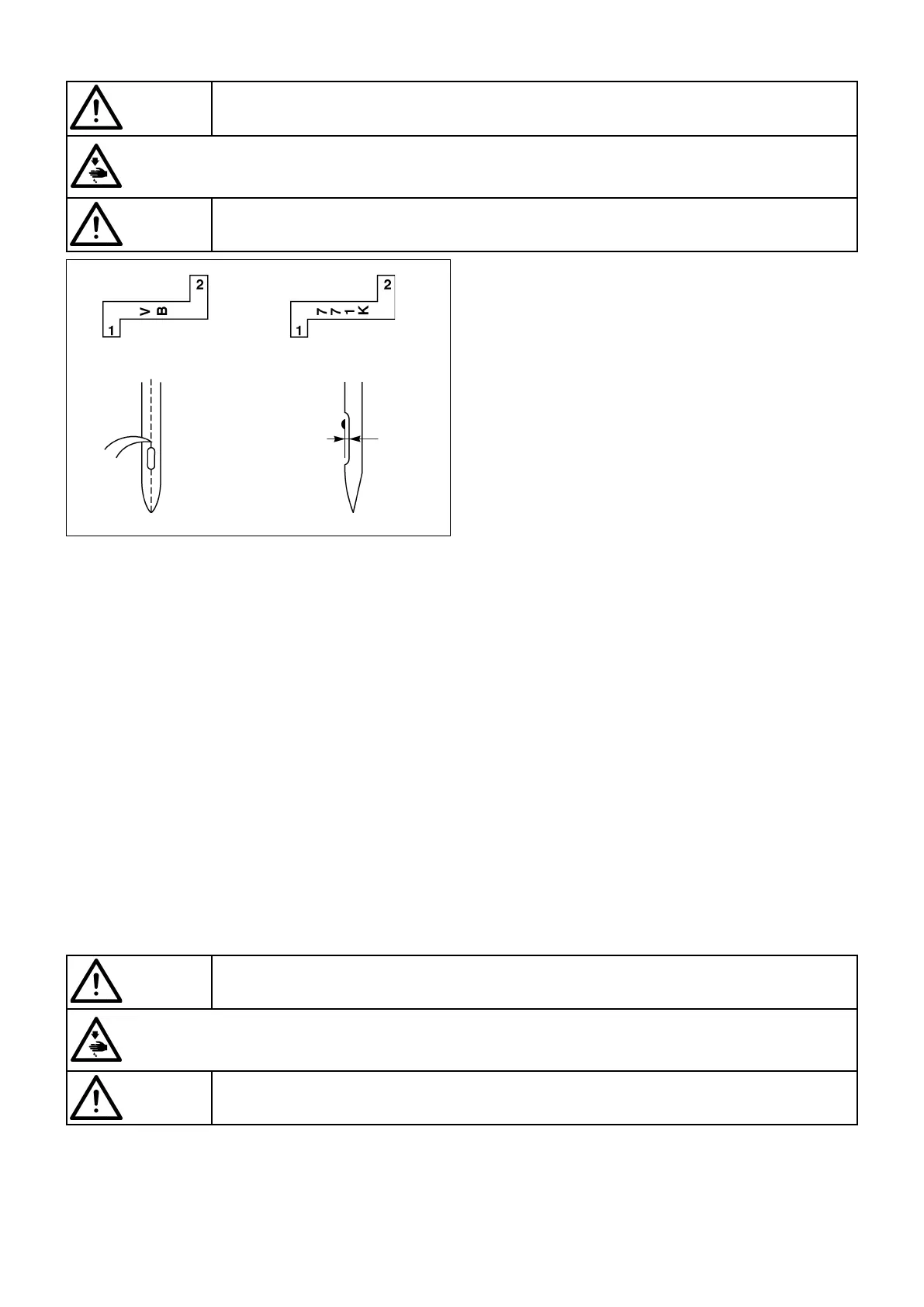

1) タイミングゲージは、NVタイプは771Kと刻印さ

れてあるもの、NBタイプはVBと刻印されてあるも

のを使用してください。タイミングの合わせ方は別

冊LBH-771-1,781の取扱説明書を参照してくだ

さい。

2) 針とかまの針先とのすき間は0.05mm(ほとんど触

れる程度)に合わせてください。

(注意) すき間が大きいと目飛びの原因となります。

それでも目飛びする場合は、さらに針とかまの

タイミングを遅らせてください。

1) Use a timing gauge that has an inscription of 771K for

NV type machine or one with an inscription of VB for

NB type machine. Refer to the separate volume of

the instruction manual for LBH-771-1 and -781 for

how to adjust the needle-to-hook timing.

2) Adjust the clearance provided between the needle

and the blade point of the hook to 0.05 mm (almost

come in contact with each other).

(Caution)

An excessive clearance between the needle and

the blade point of the hook may cause stitch

skipping. In case where stitch skipping occurs

even when the clearance between them is properly

adjusted, further retard the needle-to-hook timing.

2.糸切り装置の調整(NBタイプ)

/Adjusting the thread trimming device (NB type)

切線裝置的調整(NB 型)

(1) 案内板固定ピンと固定板のかみ合い調整

Adjusting the engagement between the guide plate locking pin and the locking plate

導板固定銷和固定板咬合的調整

1)同步標尺,NV型使用刻有771K的零件,NB型使用刻

有VB的零件。同步的調整方法請參照另外的LBH-771-

1,781 的使用說明書。

2)請把機針和旋梭尖的間隙調整為0.05 mm(大部分相接

觸)。

(注意)間隙過大的話,容易跳針。如果跳針時,請把機

針和旋梭的同步再推遲一些。

NBタイプ用

For NB type

NB 型用

NVタイプ用

For NV type

NV 型用

0.05 mm

注意

ミシンの不意の起動による事故を防ぐため、電源を切ってから行ってください。

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing

machine.

注意

為了防止縫紉機的意外起動,請關掉電源之後再進行操作。

注意

ミシンの不意の起動による事故を防ぐため、電源を切ってから行ってください。

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing

machine.

注意

為了防止縫紉機的意外起動,請關掉電源之後再進行操作。

xviii

目 錄

!. 規格 ...................................................................................................................... 3

@. 準被和運轉 ......................................................................................................... 4

1. 確認壓腳的位置 ............................................................................................................ 5

2. 確認切線動作(NB 型)................................................................................................ 5

3. 穿繩的方法 ..................................................................................................................... 6

4. 起動和提昇壓腳(NB 型)........................................................................................... 7

5. 切線(NV 型)................................................................................................................. 8

#. 調整 ...................................................................................................................... 9

1. 縫認調整 ........................................................................................................................ 9

(1)線張力的調整 .................................................................................................................................... 9

(2)挑線彈簧的調整................................................................................................................................ 9

(3)芯繩張力的調整.............................................................................................................................. 10

(4)機針和旋梭的同步 ......................................................................................................................... 11

2. 切線裝置的調整(NB 型)......................................................................................... 11

(1)導板固定銷和固定板咬合的調整 ................................................................................................ 11

(2)拉板進入量的調整 ......................................................................................................................... 12

(3)強制返回的調整.............................................................................................................................. 13

3. 芯繩導向器的調整..................................................................................................... 14

(1)芯繩導向軸動作桿板高度的調整 ................................................................................................ 14

(2)芯繩導向桿的位置調整 ................................................................................................................. 17

(3)分離時的芯繩導向桿位置的調整 ................................................................................................ 18

4. 芯繩變更同步的調整 ................................................................................................ 18

5. 移動刀、固定刀的更換(NB 型)............................................................................. 20

$. 有關暫停 ........................................................................................................... 20

%. 使用 AO-17,32 時的注意事項 ......................................................................... 21

^. 故障和對策 ....................................................................................................... 27

Loading...

Loading...