−25−

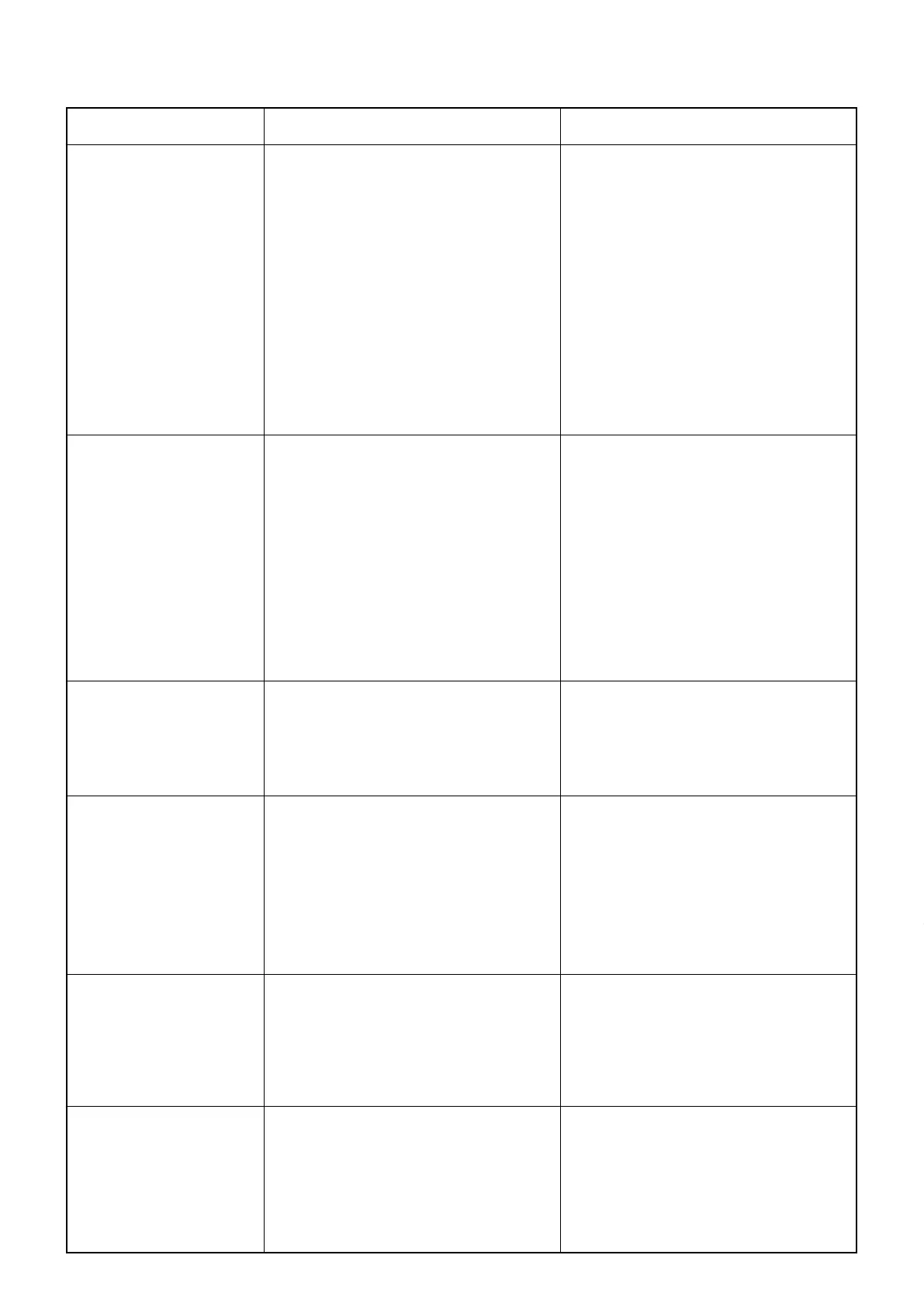

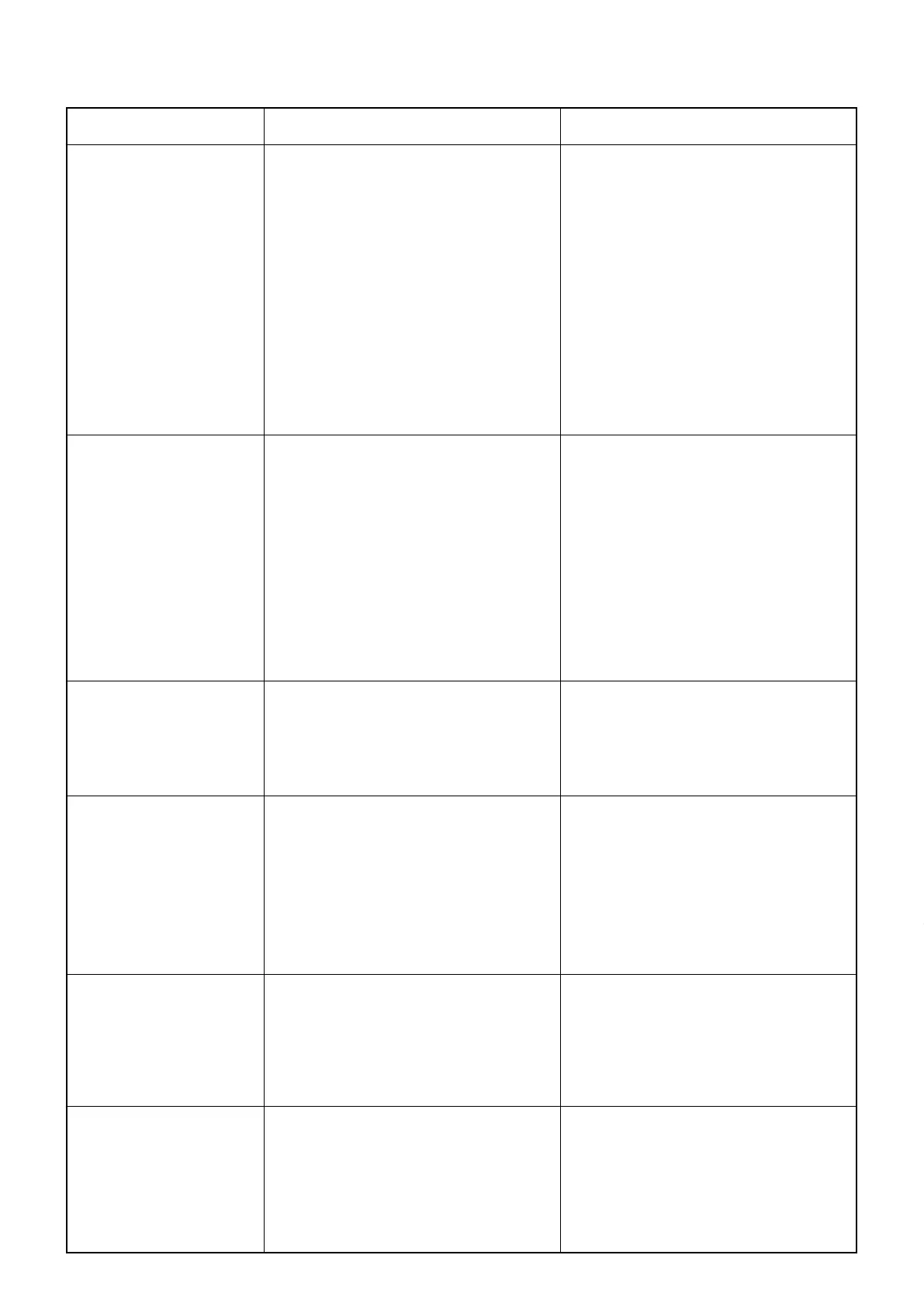

^. TROUBLES AND CORRECTIVE MEASURES

Troubles

1. Needle thread breaks.

A. The needle thread

breaks at random in the

parallel portion of a

buttonhole.

B. The needle thread

breaks at the first

bartack stitches.

C. The needle thread

breaks at the start of

sewing.

2. The needle thread slips

out of the needle eyelet at

the start of sewing.

3. The needle thread is not

cut at the time of thread

trimming.

4. The gimp cannot be cut.

5. When the gimp cutter

opens, it fails to cut the

gimp.

6. The needle breaks.

Causes

1 Thread tension is not properly adjusted.

2 Blade point of the hook has scratches.

1 The position of the gimp guide finger is too

far left from the left stitch base line and the

needle thread is caught at the top end of

the guide finger causing needle thread

breakage when shifting the stitch base line

between the left stitch base line and the

right stitch base lien.

1 Thread tension is improperly adjusted. Th

needle thread tension is particularly too

low.

1 The tension controller No. 2 provides an

excessive thread tension.

2 The needle thread and the gimp cord are

drawn by the same portion of the pull-in

plate and cut.

3 The gimp guide finger is positioned too

high, preventing the needle thread and the

bobbin thread from making knots.

1 The moving knife fails to mesh with the

stationary knife.

2 The moving knife or the stationary knife

has worn out.

1 The moving knife fails to mesh with the

stationary knife.

2 The gimp used is too thick.

3 The gimp guide finger is improperly

positioned at the time of stop motion.

1 The moving knife or the stationary knife

has worn out.

2 The needle comes in contact with the

blade point of the hook.

3 When the gimp cutter opens, the cutter

comes in contact with the the needle.

1 The needle is bent.

2 The needle comes in contact with the

blade point of the hook.

3 When the gimp cutter opens, the cutter

comes in contact with the the needle.

Corrective measures

™ Adjust first the bobbin thread tension 0.3 to

0.45N, then, adjust the needle thread

tension. (Page 9 )

™ Buff up the blade point of the hook to

remove scratches.

™ Change the position of the gimp guide

finger closer to the left stitch base line

ensuring that the gimp is neatly sewn in

the stitches. (Page 16)

™ Increase the needle thread tension. (Page

9)

(In many cases, the tension provided by

the tension controller No. 2 is too low.)

™ Decrease the thread tension provided by

the tension controller No. 2, and increase

the tension provided by the tension

controller No.1 while visually checking the

stitches. (Page 9)

™ Cut the needle thread and the bobbin

thread separately. (Page 18)

If the gimp guide finger is positioned too far

to the left at the time of stop-motion, shift it

to the right.

™ Loosen the gimp guide holder and lower

the gimp guide finger to the extent that it

does not come in contact with the retaining

spring or the work clamp check. (Page 16)

™ Adjust the position of the thread trimming

yoke so that the moving knife and the

stationary knife properly mesh with each

other. (Page 12)

™ Replace the moving knife or the stationary

knife with a new one. (Page 20)

™ Adjust the position of the thread trimming

yoke to allow the knives to mesh properly

with each other. (Page 12)

™ The cutter is capable cutting a gimp

approximately as thick as Vinylon #5. So,

replace the gimp with a thinner gimp cord.

™ Raise the position of the gimp guide finger.

At the time of stop motion, adjust the

position of the gimp guide finger. (Pages

16 and 18)

™ Replace the moving knife or the stationary

knife with a new one. (Page 20)

™ Adjust the position of the gimp guide finger

to allow the gimp to be neatly sewn in the

stitches. (Page 16)

™ Properly adjust the needle-to-hook timing.

(Page 11)

™ Replace the needle with a new one.

™ Properly adjust the needle-to-hook timing.

(Page 11)

™ Check whether the stop-motion position is

correct and also whether the locking plate

properly meshes with the guide plate

locking pin when the cutter actuates.

(Page 11)

iv

6.サーボモータをご使用の場合は、機械停止中はモータ音がしません。不意の起動による事故防止の

ため、電源の切り忘れに注意してください。

7.過熱による火災事故を防ぐため、モータ電源ボックスの冷却口をふさいで使用することはやめてく

ださい。

給 油

1.機械の給油箇所には、JUKI 純正オイル,JUKI 純正グリスを使用してください。

2.炎症,カブレを防ぐため、目や身体に油が付着した時は、直ちに洗浄してください。

3.下痢,嘔吐を防ぐため、誤って飲み込んだ場合は、直ちに医師の診断を受けてください。

保 守

1.不慣れによる事故防止のため、修理,調整は機械を熟知した保全技術者が取扱説明書の指示範囲で

行ってください。また、部品交換の際は、当社純正部品を使ってください。不適切な修理,調整お

よび非純正部品使用による事故に対しては、当社は責任を負いません。

2.不慣れによる事故や感電事故防止のため、電気関係の修理,保全 ( 含む配線 ) は、電気の専門知識

の有る人、または当社,販売店の技術者に依頼してください。

3.不意の起動による事故防止のため、エアシリンダなどの空気圧を使用している機械の修理や保全を

行う時は、空気の供給源のパイプを外し、残留している空気を放出してから行ってください。

4.人身事故防止のため、修理調整,部品交換などの作業後は、ねじ,ナットなどがゆるんでいないこ

とを確認してください。

5.機械の使用期間中は、定期的に清掃を行ってください。この際、不意の起動による事故防止のため、

必ず電源を切りミシンおよびモータが完全に停止したことを確認してから行ってください。

6.保守,点検,修理の作業の時は、必ず電源を切りミシンおよびモータが完全に停止したことを確認

してから行ってください。(クラッチモータの場合、電源を切った後もモータは惰性でしばらく回り

続けますので注意してください。)

7.人身事故防止のため、修理,調整した結果、正常に操作できない場合は直ちに操作を中止し、当社

または販売店に連絡し、修理依頼してください。

8.人身事故防止のため、ヒューズが切れた時は、必ず電源を切り、ヒューズ切れの原因を取り除いて

から、同一容量のヒューズと交換してください。

9.モータの火災事故防止のため、ファンの通気口の清掃および配線周りの点検を定期的に行ってくだ

さい。

使用環境

1.誤動作による事故防止のため、高周波ウェルダなど強いノイズ源 ( 電磁波 ) から影響を受けない環

境下で使用してください。

2.誤動作による事故防止のため、定格電圧 ±10% を超えるところでは使用しないでください。

3.誤動作による事故防止のため、エアシリンダなどの空気圧を使用している装置は、指定の圧力を確

認してから使用してください。

4.安全にお使いいただくために、下記の環境下でお使いください。

動作時 雰囲気温度 5℃〜 35℃

動作時 相対湿度 35% 〜 85%

5.電装部品損壊誤動作による事故防止のため、寒いところから急に暖かいところなど環境が変わった

時は結露が生じることがありますので、十分に水滴の心配がなくなってから電源を入れてください。

6.電装部品損壊,誤動作による事故防止のため、雷が発生している時は安全のため作業をやめ、電源

プラグを抜いてください。

7.電波状態によっては、近くのテレビ,ラジオに雑音を与えることがあります。この場合には、少し

ミシンより離してご使用ください。

8.「作業環境の騒音値が 85dB 以上 90dB 未満」に該当する環境にて仕事に従事する作業者に対して

は、健康被害を受けないよう必要に応じ、防音保護具を使用させるなどの処置をお取りください。

また、「作業環境の騒音値が 90dB 以上」に該当する環境にて仕事に従事する作業者に対しては、

健康被害を受けないよう必ず防音保護具を使用させるとともに、防音保護具の使用について作業者

の見やすい場所に掲示するようにお願いします。

9.製品や梱包の廃棄,使用済みの潤滑油などの処理は、各国の法令に従って適正に行ってください。

Loading...

Loading...