xvii

CONTENTS

!. SPECIFICATIONS ............................................................... 2

@. PREPARATION AND OPERATION .................................... 4

1. Checking the position of the work clamp check ....................................... 5

2. Checking the thread trimming action (NB type) ....................................... 5

3. Passing gimp through the machine head .................................................. 6

4. Starting the machine and lifting the work clamp check (NB type) .......... 7

5. Thread trimming (NV type) .......................................................................... 8

#. ADJUSTMENT .................................................................... 9

1. Adjusting the seam quality ......................................................................... 9

(1) Adjusting the thread tension ........................................................................................ 9

(2) Adjusting the thread take-up spring ............................................................................. 9

(3) Adjusting the gimp tension ......................................................................................... 10

(4) Needle-to-hook timing.................................................................................................11

2. Adjusting the thread trimming device (NB type) ................................... 11

(1) Adjusting the engagement between the guide plate

locking pin and the locking plate ................................................................................11

(2) Adjusting the operating depth of the pull-in plate ....................................................... 12

(3) Adjusting the forced returning mechanism................................................................. 13

3. Adjusting the gimp guide .......................................................................... 14

(1) Adjusting the height of gimp guide shaft actuating rod plate ..................................... 14

(2) Adjusting the position of the gimp guide finger .......................................................... 16

(3) Adjusting the position of the gimp guide finger at the time of stop motion ................. 18

4. Adjusting the timing to shift the gimp position between

the stitch base lines................................................................................... 18

5. Replacing the moving knife and the stationary knife (NB type) ............ 20

$. EMERGENCY STOP ......................................................... 20

%. WHEN OPERATING A MACHINE EQUIPPED

WITH AO-17 OR AO-32 .................................................... 21

^. TROUBLES AND CORRECTIVE MEASURES................. 25

−12−

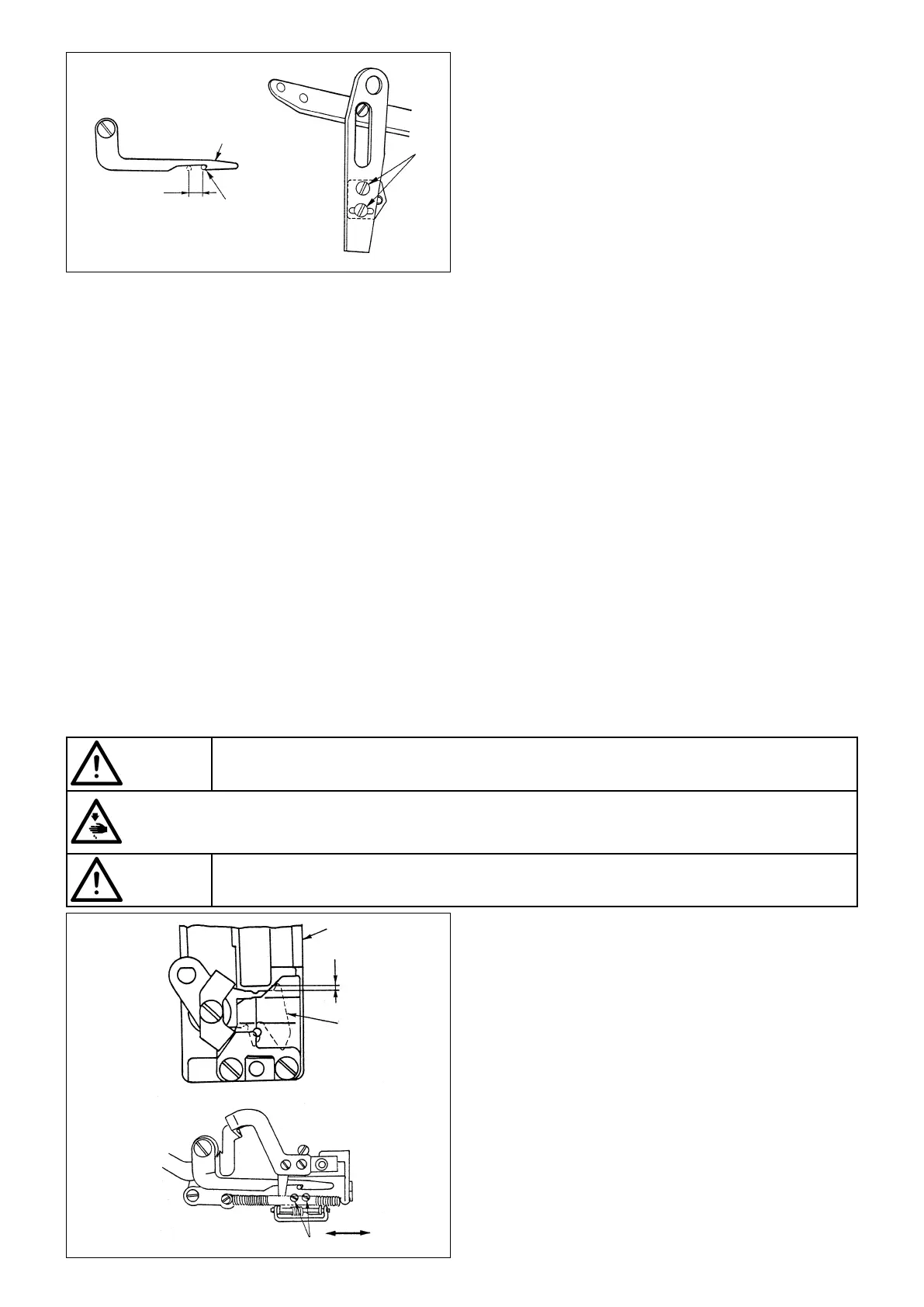

(2)たぐり板入り量の調整/Adjusting the operating depth of the pull-in plate

拉板進入量的調整

1)手動送りハンドルを回して、遮断の位置に押えを

持っていきます。

2)押え上げを行い、たぐり板1 が押え2の長穴より

0.5〜1mmほど入り込んでいるように、二又支え

板止めねじ3をゆるめて矢印方向に移動させ調整し

ます。

3)二又支え板止めねじ3を締めてください。

(注意)案内板固定ピンと固定板のかみ合いを調整

(P.11参照)した後に、上記調整を行ってくだ

さい。

1

2

3

0.5 – 1 mm

1)手動送りハンドルを回して、遮断の位置に押えを

持っていきます。

2)押え上げを行い、案内板固定ピン1が最大に動作し

た時と固定板2とかみ合った時の移動量が0.5〜1

mmとなるように、止めねじ3をゆるめて調整しま

す。

3)止めねじ3を締めてください。

(注意)

移動量が大きいと、押え上げができなかったり、た

ぐり板の上に針が落ちてメス等が破損し、針が折れ

てしまいます。

(「2.糸切り動作の確認」(P.5)を参照してくださ

い。)

1) Turn the manual feed handle to make the work clamp

check to travel to the stop-motion position.

2) Loosen screws 3 and lift the work clamp check to

make guide plate locking pin 1 to reach its travel end

and engage with locking plate 2. At this time, adjust

the amount the travel of the guide plate locking plate

to 0.5 to 1 mm.

3) Tighten screws 3.

(Caution)

If the traveling amount of the guide plate locking

pin is too large, the needle may drop on the pull-in

plate to cause the knife or the related components

and the needle to break.

(Refer to “2. Checking the thread trimming action”

on page 5.)

1)轉動手動送布手柄,把壓腳抬到分離的位置。

2)提昇壓腳,擰鬆固定螺絲3,在導向板固定銷1動作

最大時與固定板 2 咬合的移動量調整為 0.5 ∼ 1 mm 。

3)擰緊固定螺絲 3 。

(注意)移動量過大的話,壓腳不能提昇,機針落到拉板

上,弄壞切刀,弄斷機針。

(請參照「2. 切線動作的確認」(P.5)。)

注意

ミシンの不意の起動による事故を防ぐため、電源を切ってから行ってください。

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing

machine.

注意

為了防止縫紉機的意外起動,請關掉電源之後再進行操作。

1

3

2

0.5 – 1 mm