6-8

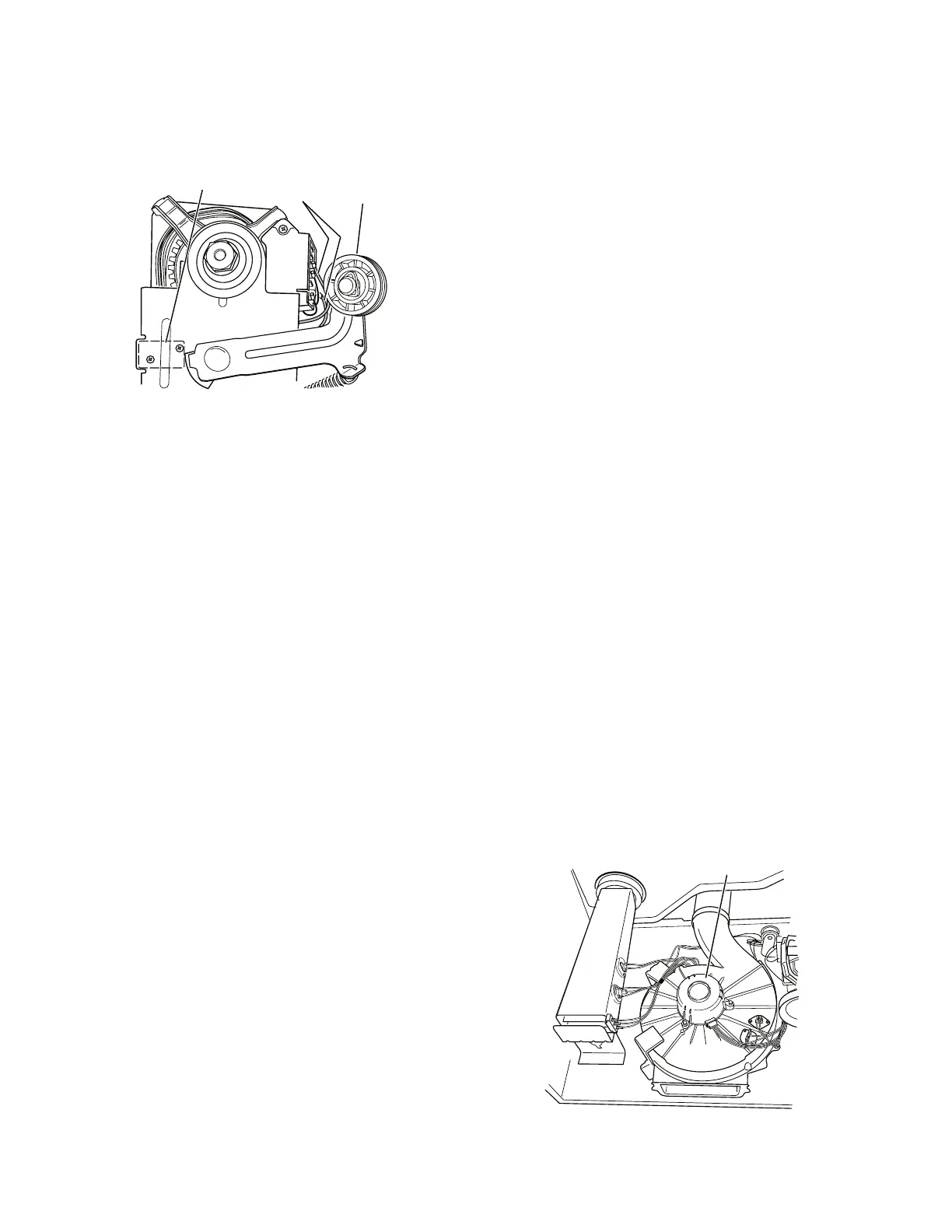

8. Check the belt switch by measuring re-

sistance between the two blue wires, as

shown in Figure 8, while pushing up the

belt switch pulley.

If the resistance reading goes from in

-

finity to a few ohms as pulley arm clos

-

es the switch, belt switch is OK. If not,

replace the belt switch.

If belt switch is OK and there is still an

open circuit, check and repair the wir-

ing harness.

9. Door switch problems can be uncovered

in the Door Switch Diagnostic Test; how

-

ever, if this was not done, the following

can be done without applying power to

the dryer. Connect an ohmmeter across

P8-3 (neutral, white wire) and P8-4 (door,

tan wire).

With the door properly closed, the ohm-

meter should indicate a closed circuit

(0–2 ohms).

If not, replace the door switch assem

-

bly. See Figure 12; and Removing the

Front Panel/Drum Assembly.

TEST #3b Blower Motor (Dual Motor Model)

1. Access the motor control electronics. See

Accessing & Removing the Electronic As

-

semblies.

2. Visually check the communication har-

ness. See Figure 15. The communication

harness is a three-wire harness that con

-

nects between the two electronic control

assemblies. Make sure it is fully inserted

into both electronic controls.

•

•

•

•

2

6

4

3

5

1

Belt Switch

Tension

Pulley

Blue Wires

(Back and 4 position)

Figure 8. Checking the belt switch.

3. If the communication harness looks OK,

go to step 4.

4. Visually check the wire harnesses con-

nected to the motor control electronic

assembly. Make sure they are clean and

fully inserted into the control.

If the connections look OK, go to step 5.

5. Remove the MC2 blower motor electrical

connector from the blower motor elec

-

tronic control.

6. Measure the resistance between the fol-

lowing terminals on the connector: pins

1 to 3, 1 to 5 and 3 to 5. The resistance

should be between 55 and 65 ohms.

If the resistance looks OK, go to step 7.

If the resistance is much greater than

65 ohms, go to step 7.

If the resistance is much less than 55

ohms, replace the blower motor.

7. Visually check the wire harness connec-

tion at the blower motor (See Accessing

the Blower Motor below).

If the connections look OK, check for

obstructions in the blower housing.

Make sure blower fan rotates freely.

If no obstructions are found, replace

the motor control electronic assembly.

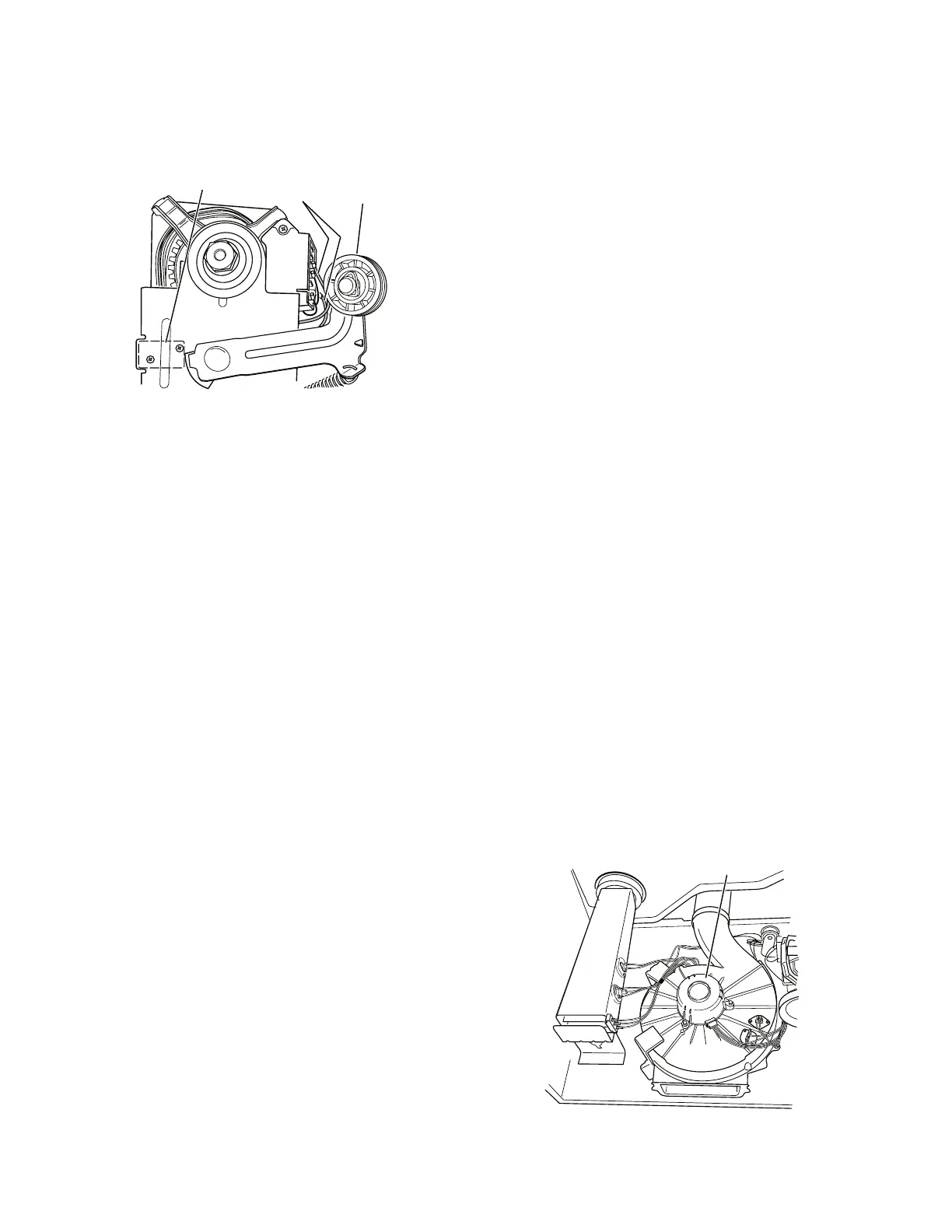

Accessing the Blower Motor:

Follow the steps under Removing the Front

Panel/Drum Assembly. The blower motor is

located on top of the blower housing as shown

in Figure 9.

•

•

•

•

•

•

Blower Motor

Figure 9. Blower motor location.

Loading...

Loading...