28

EN

Once all (and not just some) of the system devices have passed the

testing procedure, the system can be commissioned;

the system’s technical dossier must be produced and kept for 10

years. It must contain the electrical wiring diagram, a drawing or

photograph of the system, the analysis of the risks and the solutions

adopted to deal with them, the manufacturer’s declaration of con-

formity for all connected devices, the operator’s manual for every

device and the system maintenance plan;

x a dataplate with the details of the automation, the name of the

person who commissioned it, the serial number and year of con-

struction and the CE marking on the gate or door;

also t a sign specifying the procedure for releasing the system by

hand;

draw up the declaration of conformity, the instructions and precau-

tions for use for the end user and the system maintenance plan and

consign them to the end user;

ensure that the user has fully understood how to operate the system

in automatic, manual and emergency modes;

the end user must also be informed in writing about any risks and

hazards still present;

ATTENTION !

After detecting an obstacle, the gate or door stops during its

opening travel and automatic closure is disabled; to restart

operation, the user must press the control button or use the

transmitter.

5 - TESTING AND COMMISSIONING THE AUTOMATION SYSTEM

All system components must be tested following the procedures de-

scribed in their respective operator’s manuals;

ensure that the recommendations in Chapter 1 - Safety Warnings -

have been complied with;

check that the gate or door is able to move freely once the automa-

tion system has been released and is well balanced, meaning that it

will remain stationery when released in any position;

check that all connected devices (photocells, sensitive edges, emer-

gency buttons, etc.) are operating correctly by performing gate or

door opening, closing and stop tests using the connected control

devices (transmitters, buttons or switches);

perform the impact measurements as required by the EN 12453,stan-

dard, adjusting the control unit’s speed, motor force and decelera-

tion functions if the measurements do not give the required results,

until the correct setting is obtained.

The system must be tested by a qualied technician, who must per-

form the tests required by the relevant standards in relation to the

risks present, to check that the installation complies with the relevant

regulatory requirements, especially the EN 12453, standard which

species the test methods for gate and door automation systems.

6 - FURTHER DETAILS - ADVANCED MENU

The ADVANCED MENU allows the system to be further customised

by modifying parameters not accessible from the basic menu.

To access the ADVANCED menu, press the MENU key and hold

it down for 5 seconds.

* For TUS4324 and SUN5324 max= 2

** For TUS4324 and SUN5324 max = 15

To modify ADVANCED MENU parameters, proceed as described

for the BASIC MENU.

N.B. Some default functions/display items may vary with respect to

the type of motor selected.

5.1 Testing

5.2 Commissioning

10

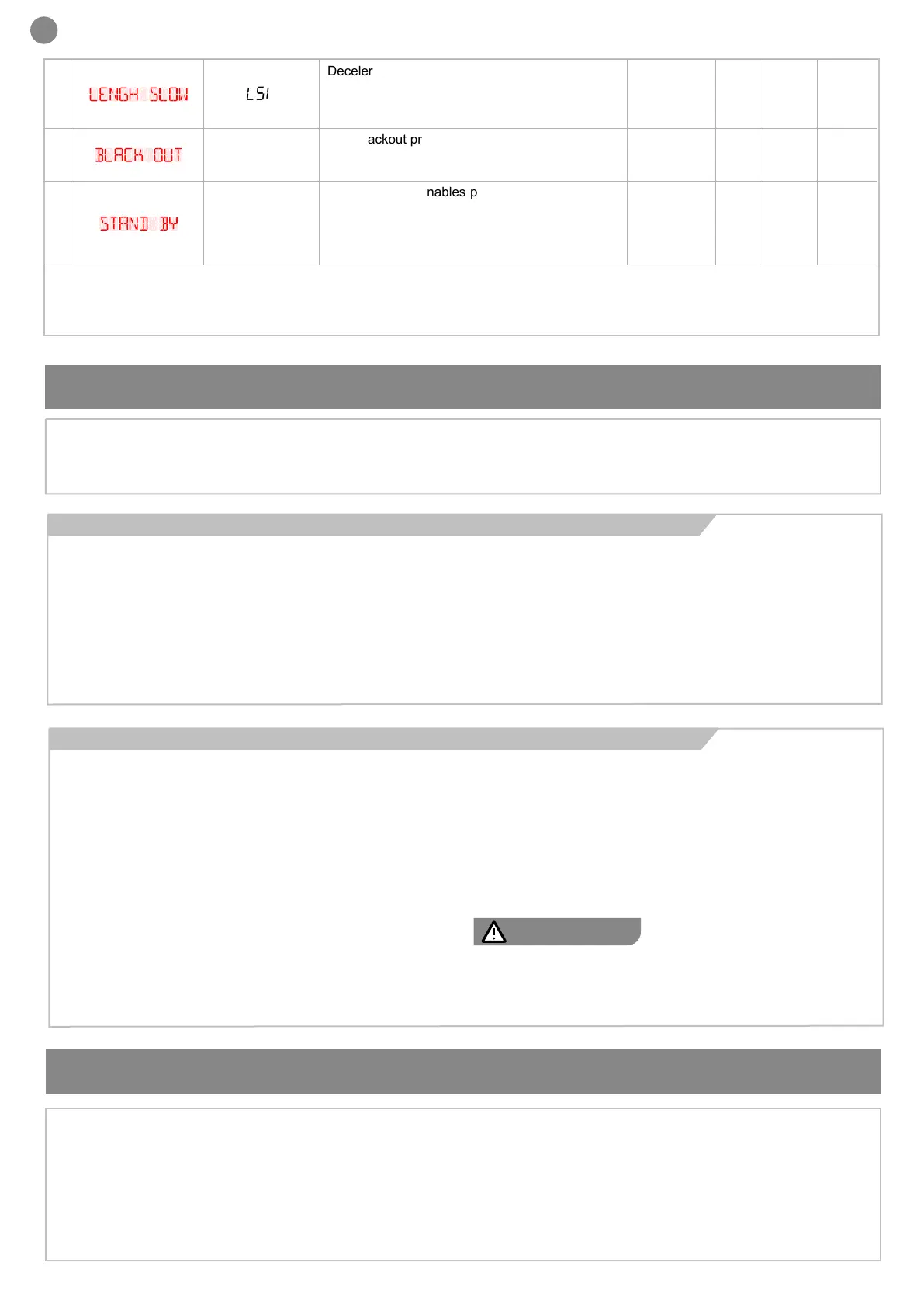

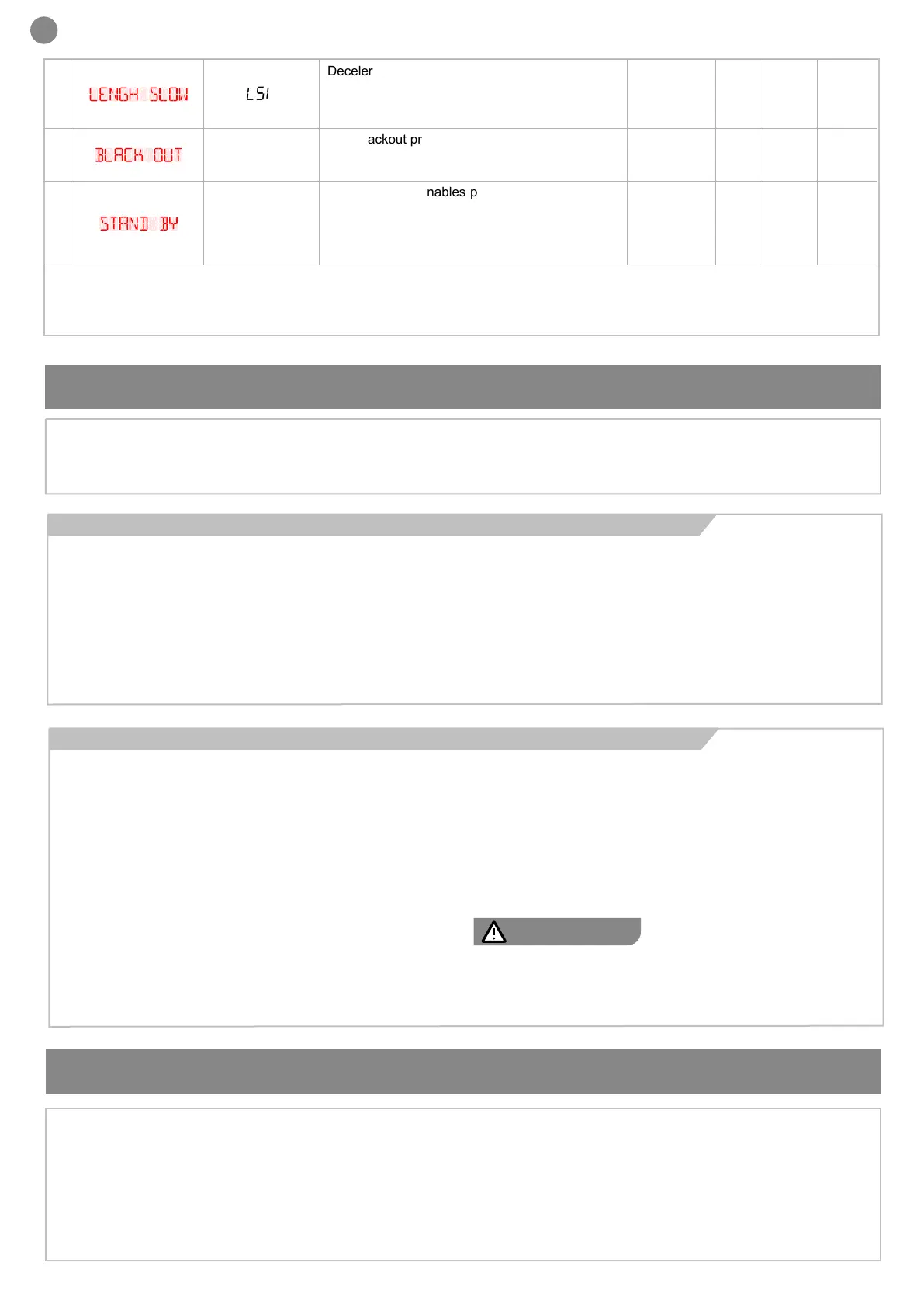

lengh slow

LSI

Deceleration distance

1 to 100 = Motor deceleration percentage during

opening and closure

P= customized decelerations

20 1** 100 %

11

black out

BlT

Post blackout procedure

0 = No action, remains stationery

1 = Closure

0 0 1

12

stand by

SBY

Energy saving: enables photocell switch-o when

gate is closed (only during this function PHOTO-

TEST is not possible)

0= disabled

1= enabled

0 0 1

Loading...

Loading...