Valve Seat Inserts

Hardened steel alloy intake and exhaust valve seat inserts are press fi tted into cylinder head. Inserts are not

replaceable but can be reconditioned if not too badly pitted or distorted. If cracked or badly warped, cylinder head

should be replaced.

Recondition valve seat inserts following instructions provided with valve seat cutter being used. Final cut should

be made with an 89° cutter as specifi ed for valve seat angle. Cutting proper 45° valve face angle as specifi ed, and

proper valve seat angle (44.5°, half of full 89° angle), will achieve desired 0.5° (1.0° full cut) interference angle where

maximum pressure occurs on outside diameters of valve face and seat.

Lapping Valves

NOTE: Exhaust valves that are black in color cannot be ground and do not require lapping.

Reground or new valves must be lapped in, to provide proper fi t. Use a hand valve grinder with a suction cup for fi nal

lapping. Lightly coat valve face with a fi ne grade of grinding compound, then rotate valve on its seat with grinder.

Continue grinding until a smooth surface is obtained on seat and on valve face. Thoroughly clean cylinder head in

soap and hot water to remove all traces of grinding compound. After drying cylinder head, apply a light coating of SAE

10 oil to prevent rusting.

Valve Stem Seal

These engines use valve stem seals on intake and exhaust valves. Always use a new seal when valves are removed

from cylinder head. Seals should also be replaced if deteriorated or damaged in any way. Never reuse an old seal.

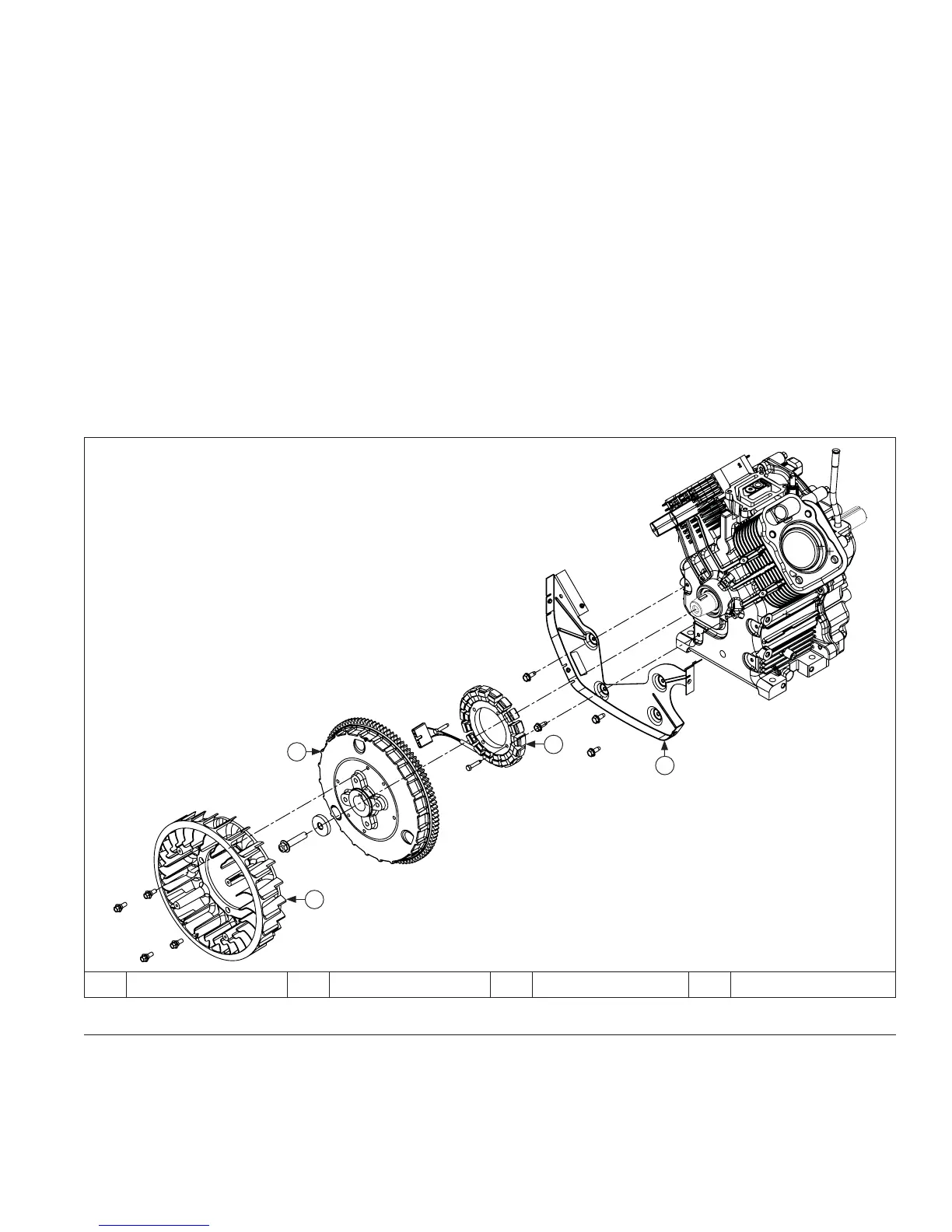

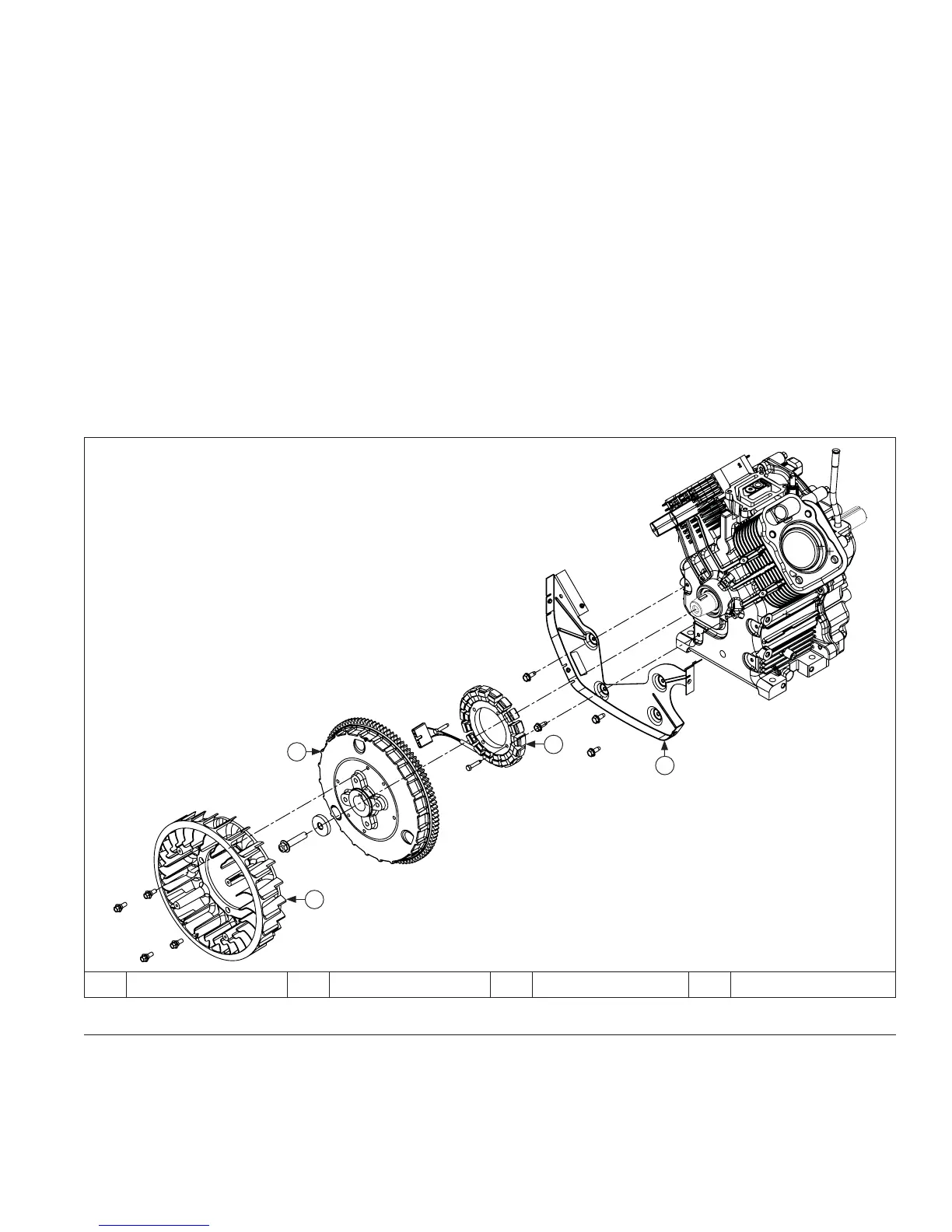

Flywheel Components

A

B

D

C

A Flywheel Fan B Flywheel C Stator D Backing Plate

Remove Fan and Flywheel

NOTE: Always use a fl ywheel strap wrench or holding tool to hold fl ywheel when loosening or tightening fl ywheel

screw. Do not use any type of bar or wedge to hold fl ywheel. Use of such tools could cause fl ywheel to

become cracked or damaged.

NOTE: Always use a fl ywheel puller to remove fl ywheel from crankshaft. Do not strike crankshaft or fl ywheel, as

these parts could become cracked or damaged. Striking puller or crankshaft can cause crank gear to move,

affecting crankshaft endplay.

Disassembly/Inspection and Service

11324 690 01 Rev. K KohlerEngines.com

Loading...

Loading...