24 690 01 Rev. KKohlerEngines.com92

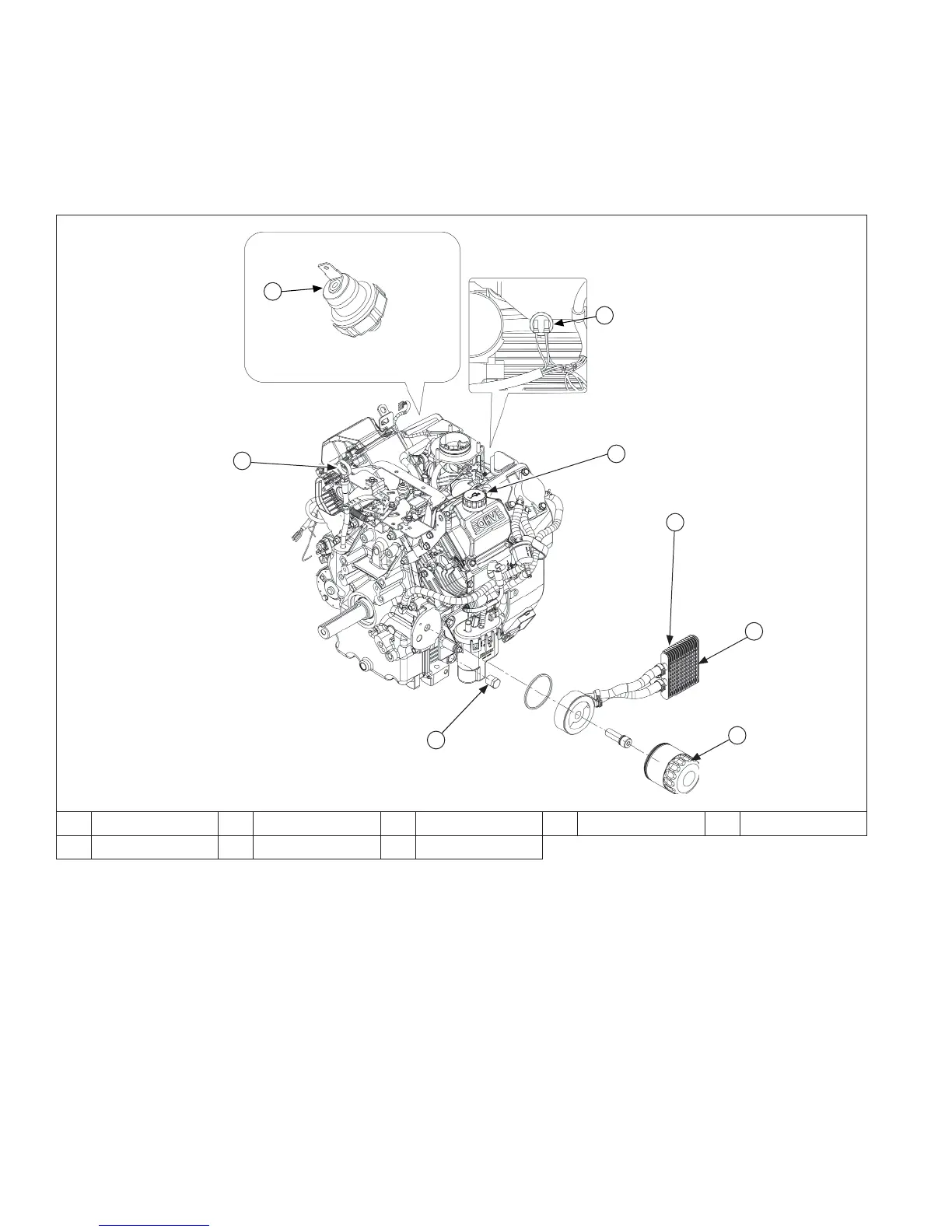

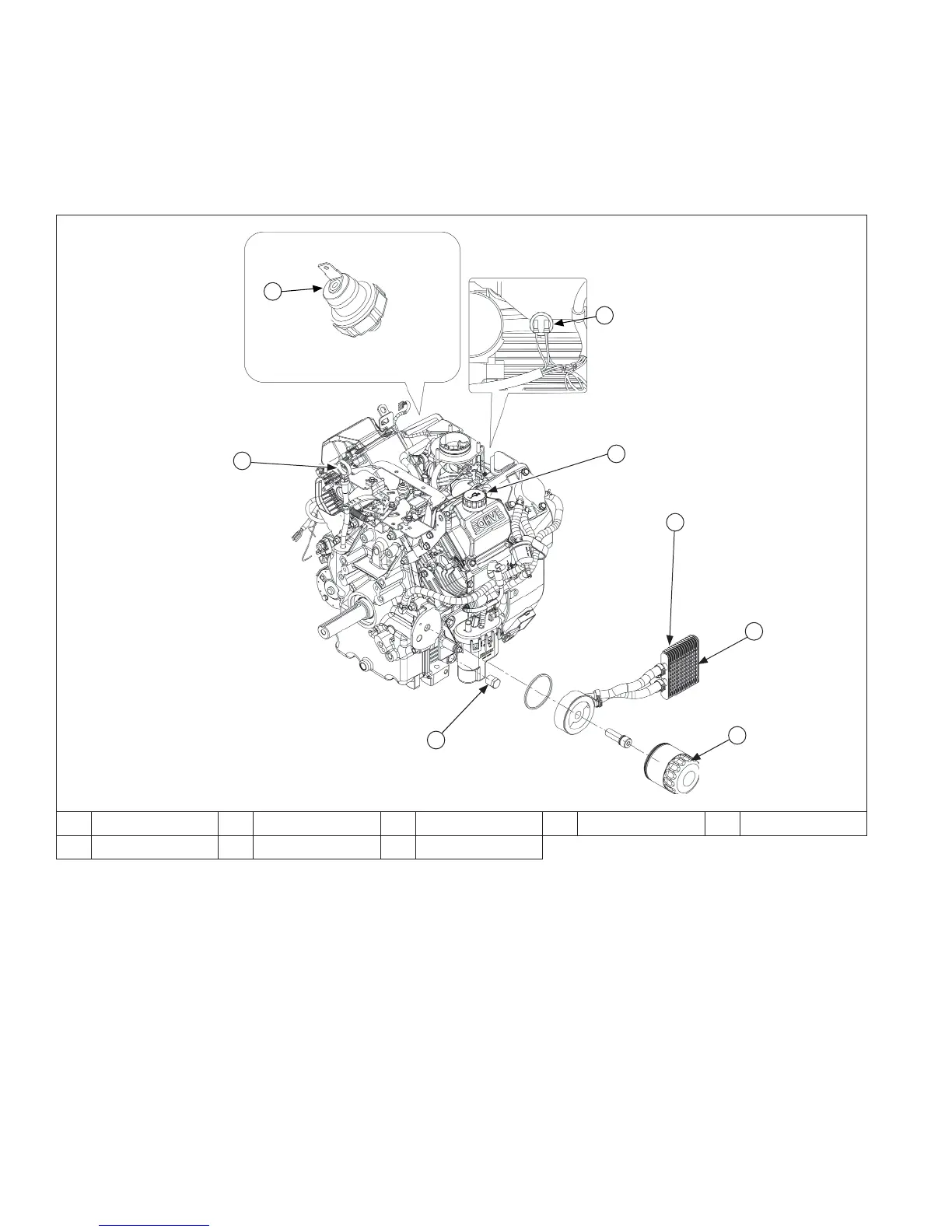

Lubrication System

This engine uses a full pressure lubrication system which delivers oil under pressure to crankshaft, camshaft,

connecting rod bearing surfaces, and hydraulic valve lifters.

A high-effi ciency gerotor oil pump maintains high oil fl ow and oil pressure, even at low speeds and high operating

temperatures. A pressure relief valve limits maximum pressure of system. Oil pan must be removed to service oil

pickup, pressure relief valve, and oil pump.

Lubrication Components

A

H

G

B

C

D

E

F

A Oil Filter B Back Side C Oil Cooler D Oil Drain Plug E Oil Fill Cap

F Oil Fill/Dipstick G Pressure Switch H Oil Sentry

TM

OIL RECOMMENDATIONS

Refer to Maintenance.

CHECK OIL LEVEL

NOTE: To prevent extensive engine wear or damage, never run engine with oil level below or above operating range

indicator on dipstick.

Ensure engine is cool. Clean oil fi ll/dipstick areas of any debris.

1. Remove dipstick; wipe oil off.

a. Push-on cap: reinsert dipstick into tube; press completely down.

or

b. Threaded cap: reinsert dipstick into tube; rest cap on tube, do not thread cap onto tube.

2. Remove dipstick; check oil level. Level should be at top of indicator on dipstick.

3. If oil is low on indicator, add oil up to top of indicator mark.

4. Reinstall and secure dipstick.

Loading...

Loading...