METHOD FOR CHECKING IDLER OIL LEVEL

WARNING

When the oil level is low and new oil must be added, the machine body needs to be inclined, and that is

dangerous.

Ask your Komatsu distributor for adding.

Low oil level in the idler can cause noise and seizure. Stop the machine on a flat place and check for the oil

level according to the following procedure.

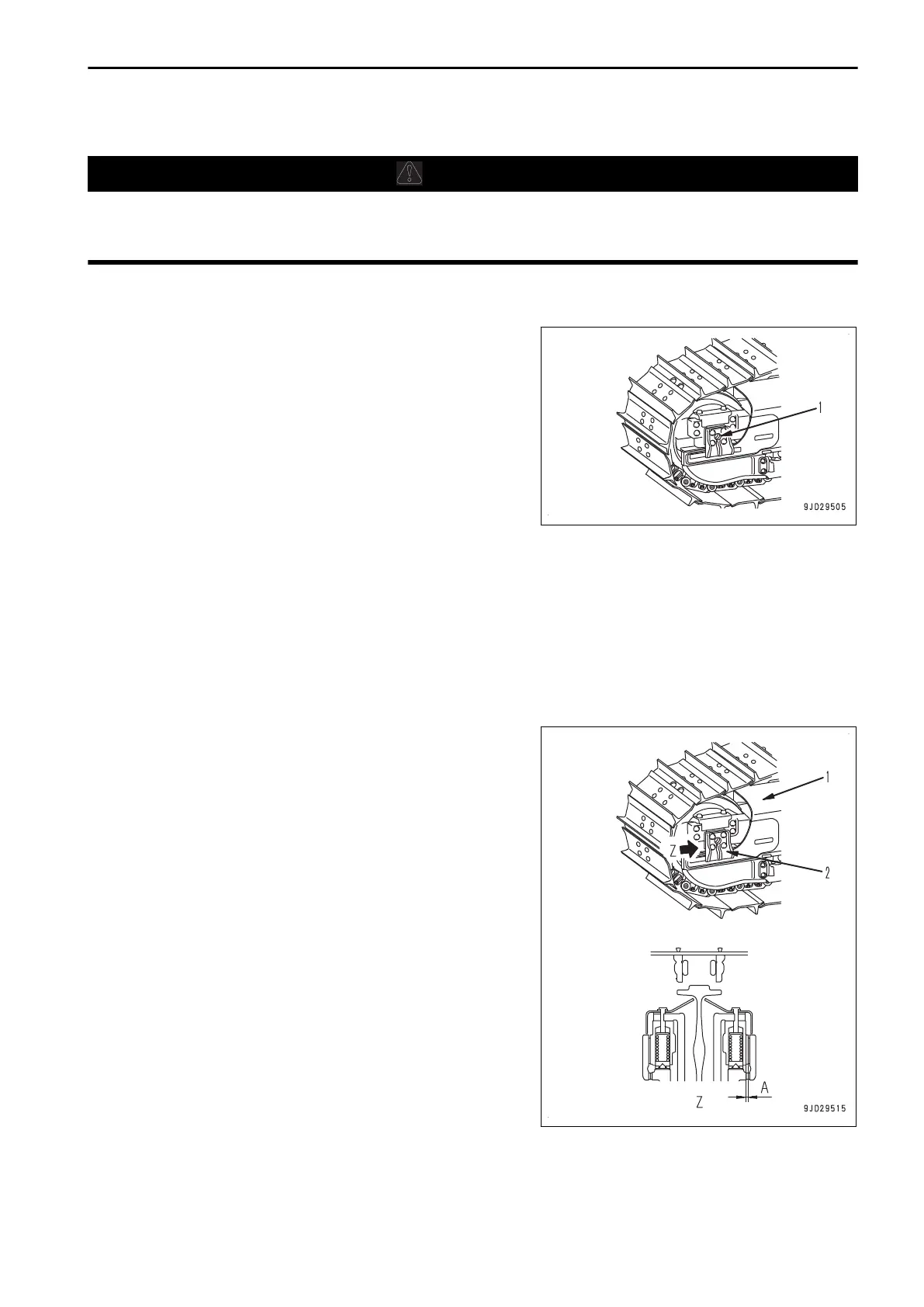

1.

Loosen plug (1) gradually and check that oil oozes out

through the thread portion.

•

When oil oozes out through thread portion

You do not need to add oil.

• When no oil oozes out through thread portion

The oil is insufficient. Ask your Komatsu distributor for

adding.

2.

After checking, tighten plug (1).

METHOD FOR ADJUSTING IDLER CLEARANCE

Since the idlers are forced to move forward and backward by an external force, guide plates will be worn out.

W

ear of guide plates will cause the vibration of idlers from side to side or inclination of the idlers, and running off

of track links from the idlers or unevenly worn idler and links may result.

Adjust as follows.

METHOD FOR ADJUSTING IDLER CLEARANCE HORIZONTALLY

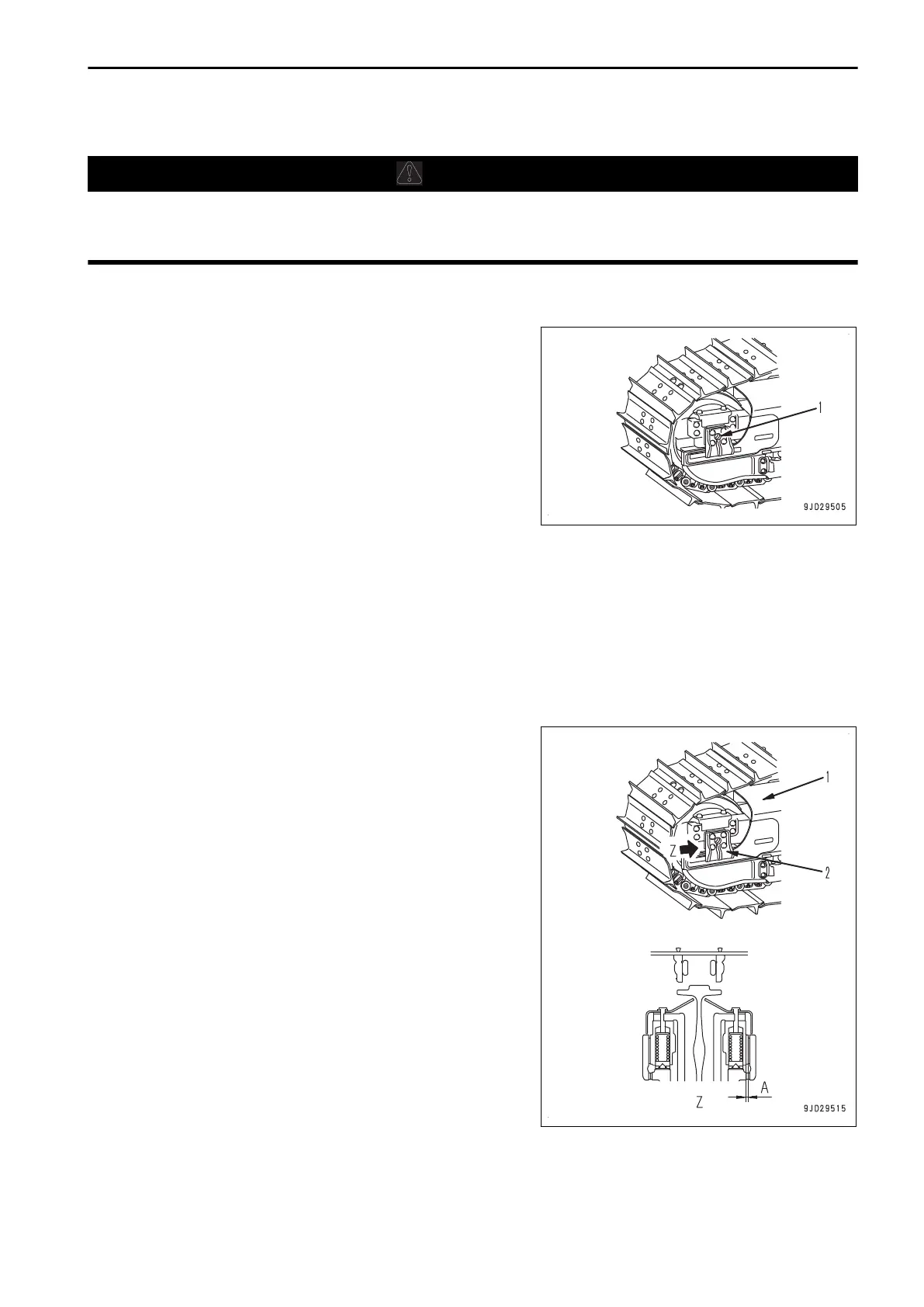

1.

Drive the machine by 1 to 2 m on a flat place.

2.

Measure the clearance (A) between track frame (1) and

guide

plate (2) (4 places on the right and left, and inside

and outside).

• When clearance (A) is less than 4 mm.

The clearance of the idler does not need to be adjus-

ted.

• When clearance (A) is 4 mm or more

Adjust the clearance of the idler.

MAINTENANCE MAINTENANCE PROCEDURE

4-27

Loading...

Loading...