CHECK AND MAINTENANCE

EVER

Y 250 HOURS MAINTENANCE

METHOD FOR LUBRICATING

1.

Lower the ripper to the ground and stop the engine.

2.

By using a grease pump, pump in grease through the grease fitting.

3.

After greasing, wipe off any old grease that is pushed out.

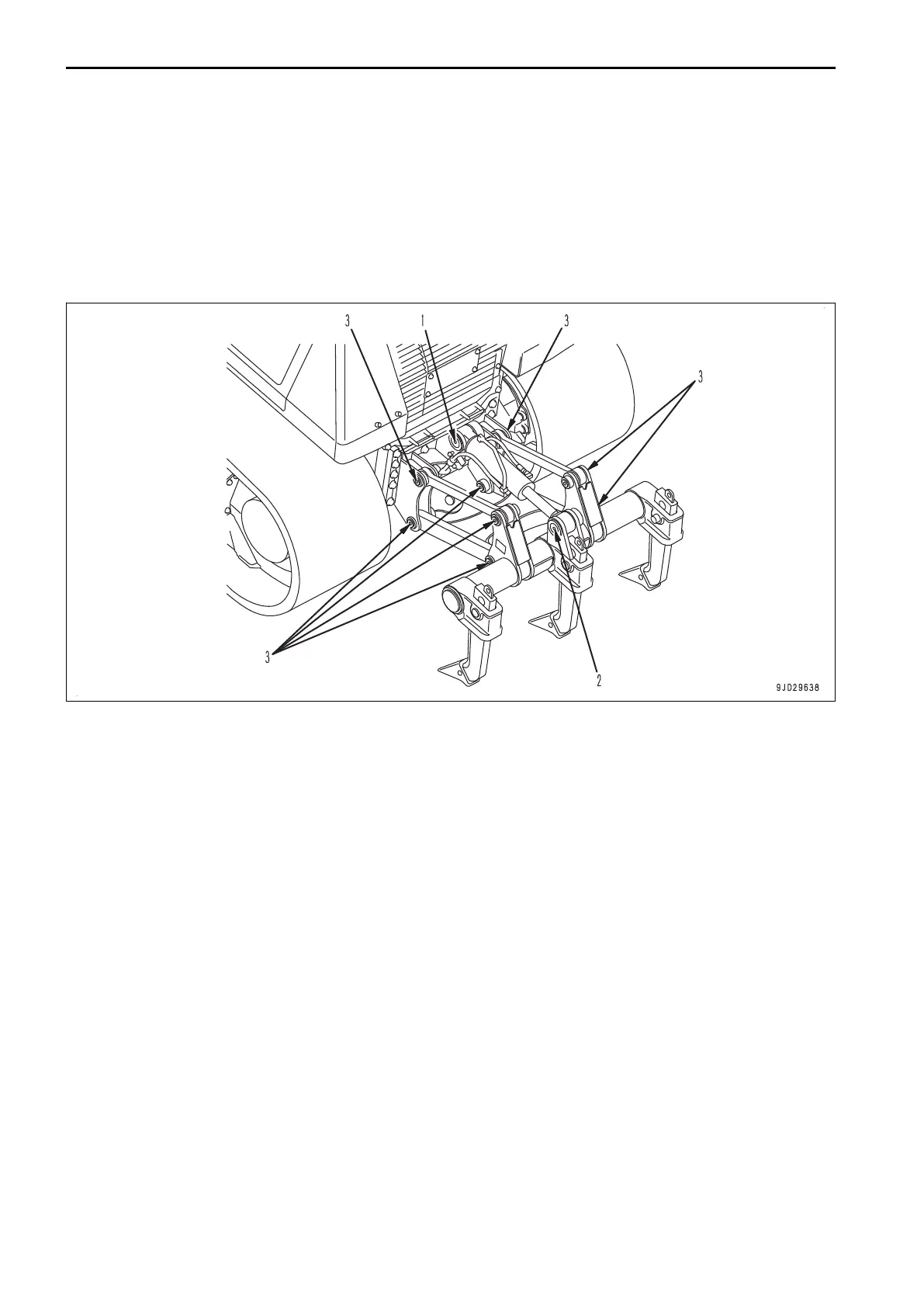

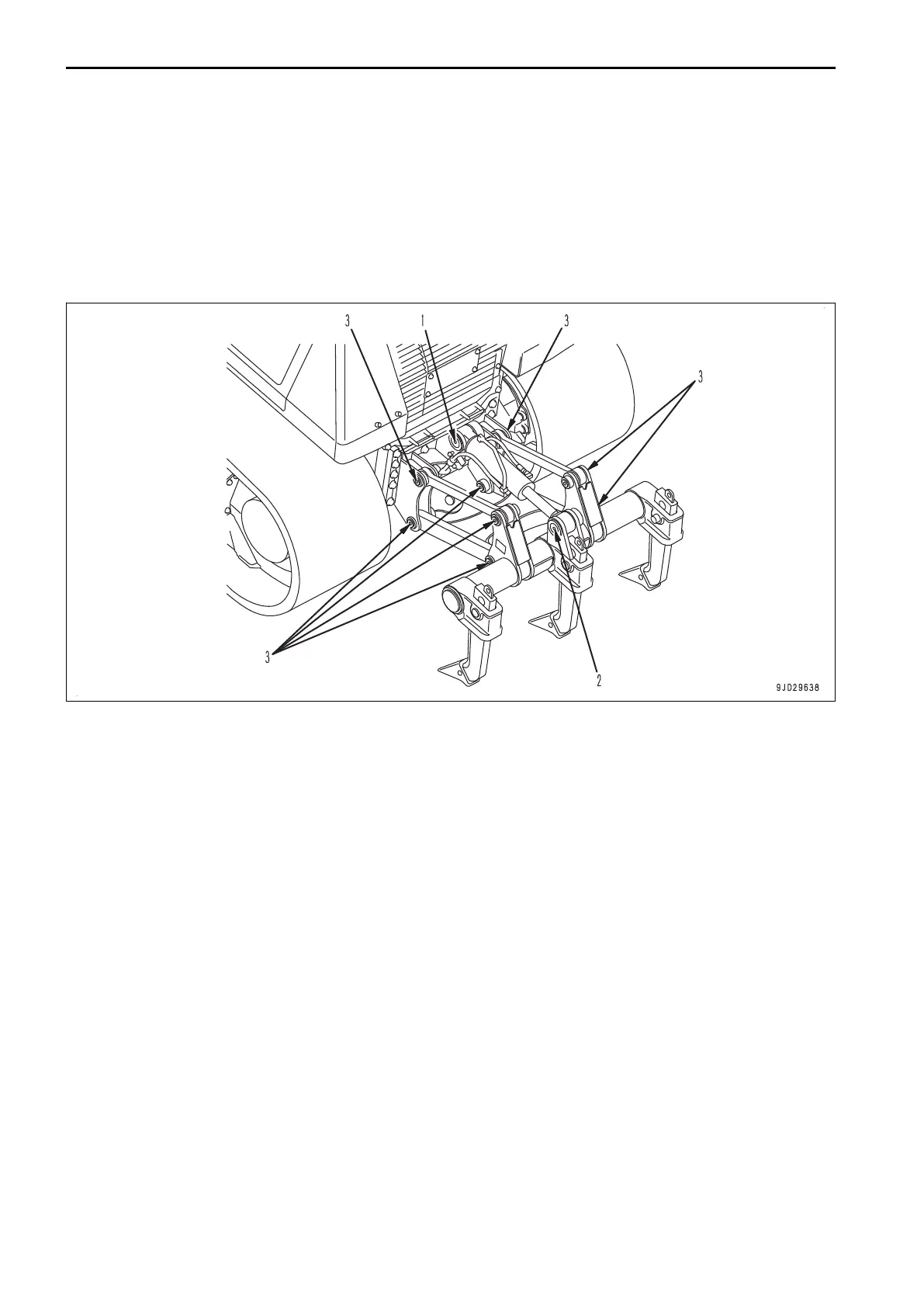

(1) Ripper cylinder foot pin (1 place)

(2) Ripper cylinder rod end pin (1 place)

(3) Link pin (8 places)

METHOD FOR CHECKING OIL LEVEL IN HYDRAULIC TANK, ADDING OIL

1.

Place the machine on a level ground and lower the work equipment to the ground.

If the machine is inclining, make it level.

2.

Make the blade perpendicular and lower it to the ground.

3.

Make the ripper point touch the ground.

4.

Stop the engine.

5.

Check oil level in hydraulic tank.

For

details, see OPERATION, “METHOD FOR CHECKING OIL LEVEL IN HYDRAULIC TANK, ADDING

OIL”.

SPECIFICATIONS: D51EX-24

Power angle power tilt dozer (Machine with ripper)

HANDLE HYDRAULIC RIPPER ATTACHMENTS AND OPTIONS

6-8

Loading...

Loading...