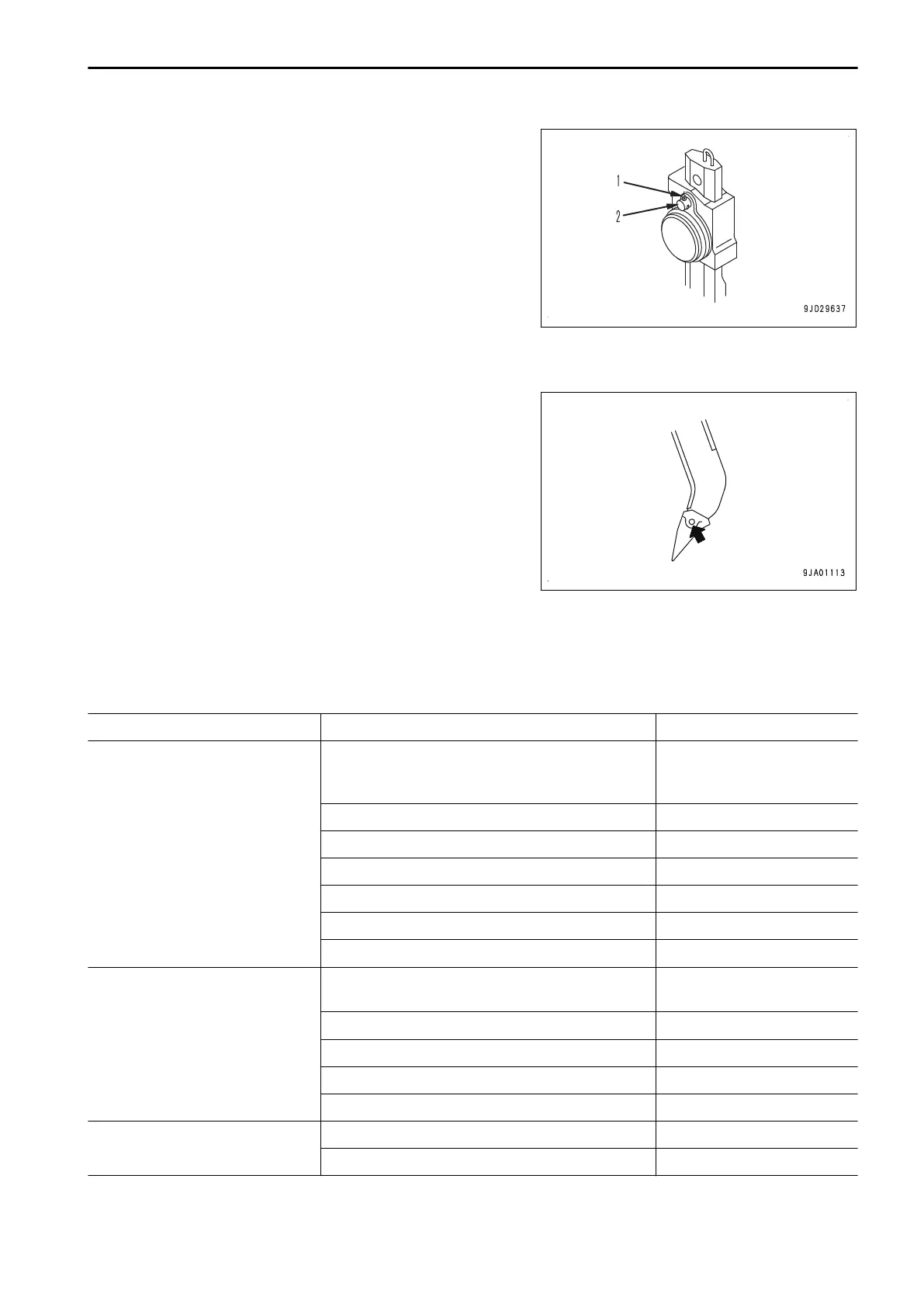

1.

Remove the cotter pin (1).

2.

Remove the pin (2).

3.

Change the shank hole position, and insert the pin (2).

4.

Insert the cotter pin (1).

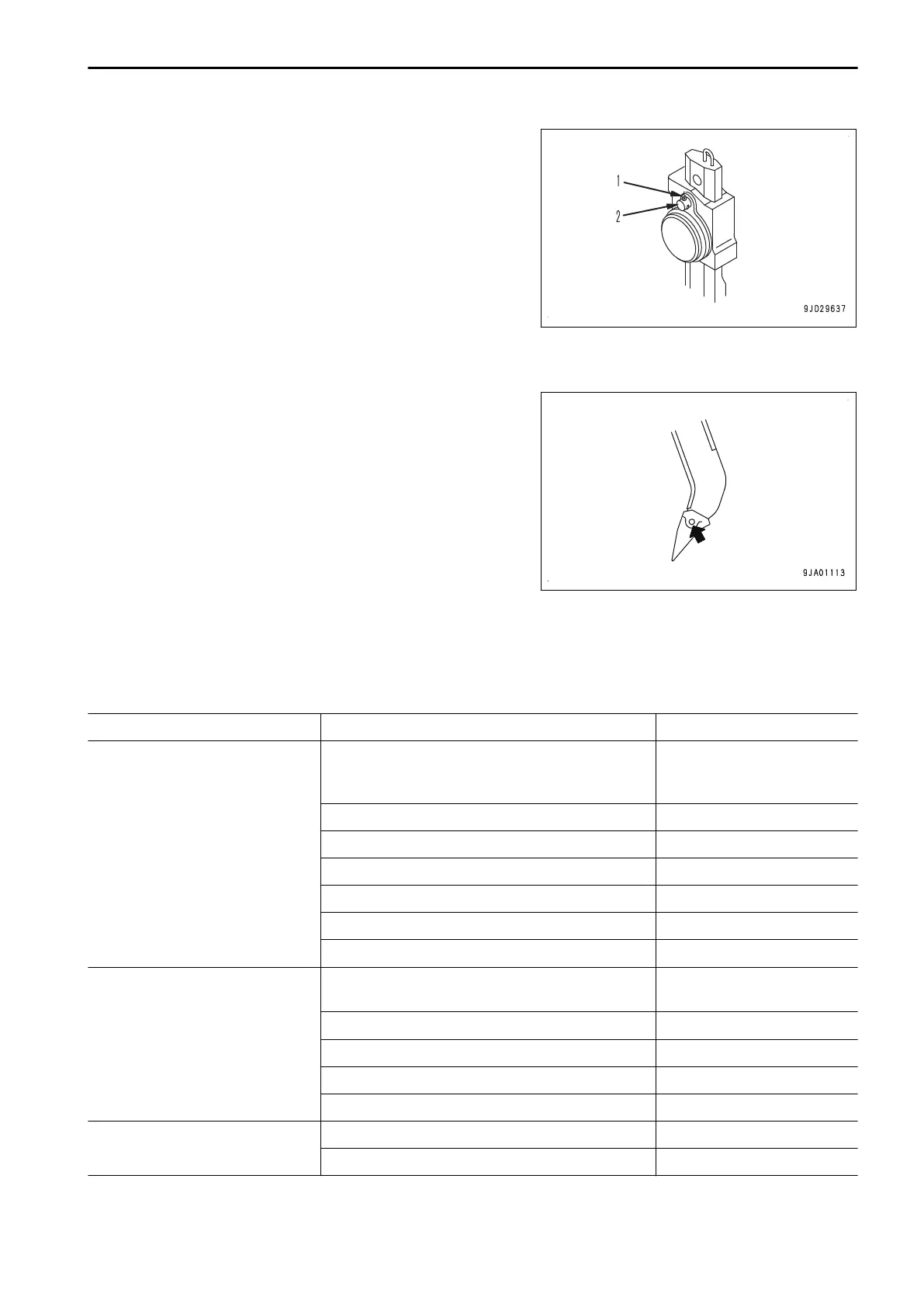

METHOD FOR REPLACING RIPPER POINT

A point is installed to protect the shank. If the point is worn, replace it according to the following procedure.

1.

Put a pin puller to the pin indicated by the arrow, and hit it

with a hammer to drive out the pin.

The pin comes of

f.

2.

Replace the point.

3.

Insert the pin halfway.

4.

Drive in the pin with the hammer.

TROUBLES AND ACTIONS

OTHER TROUBLE

• Contact your Komatsu distributor for the remedies indicated with (*) in the remedy column.

• In cases of problems or causes which are not listed below, ask your Komatsu distributor for repairs.

Problem Main causes Remedy

Lack of rising and pushing force

of ripper

Slow moving

Inappropriate hydraulic oil Add oil to specified level by

referring to EVER

Y 250

HOURS MAINTENANCE.

Defective pump Check, repair. (*)

Incorrect adjustment of relief valve Check, adjust. (*)

Defective control valve and safety valve Check, repair. (*)

Defective valve spool Check, repair. (*)

Defective piston ring, packing, or valve Check, repair. (*)

Clogging inside piping Check, repair. (*)

Cylinder lacks holding power. Leakage of oil from piping or hose Tighten, check, replace the

O-ring or hose.

Defective piston ring or packing Replace. (*)

Defective piston valve Check, repair. (*)

Defective valve spool Check, repair. (*)

Defective safety valve, defective suction valve Check, repair. (*)

Oil pressure does not rise. Clogging inside piping Repair. (*)

Incorrect adjustment of relief valve Check, adjust. (*)

ATTACHMENTS AND OPTIONS HANDLE HYDRAULIC RIPPER

6-7

Loading...

Loading...