.

MAINTENANCE

SERVICE PROCEDURE

REPLACE TRANSMISSION OIL FILTER ELEMENT

WARNING

The parts and oil are at high temperature immediately after the engine is stopped, and may cause burns. Wait for the

temperature to go down before starting the work.

When removing the oil filler cap, turn it slowly to release the internal pressure, then remove it.

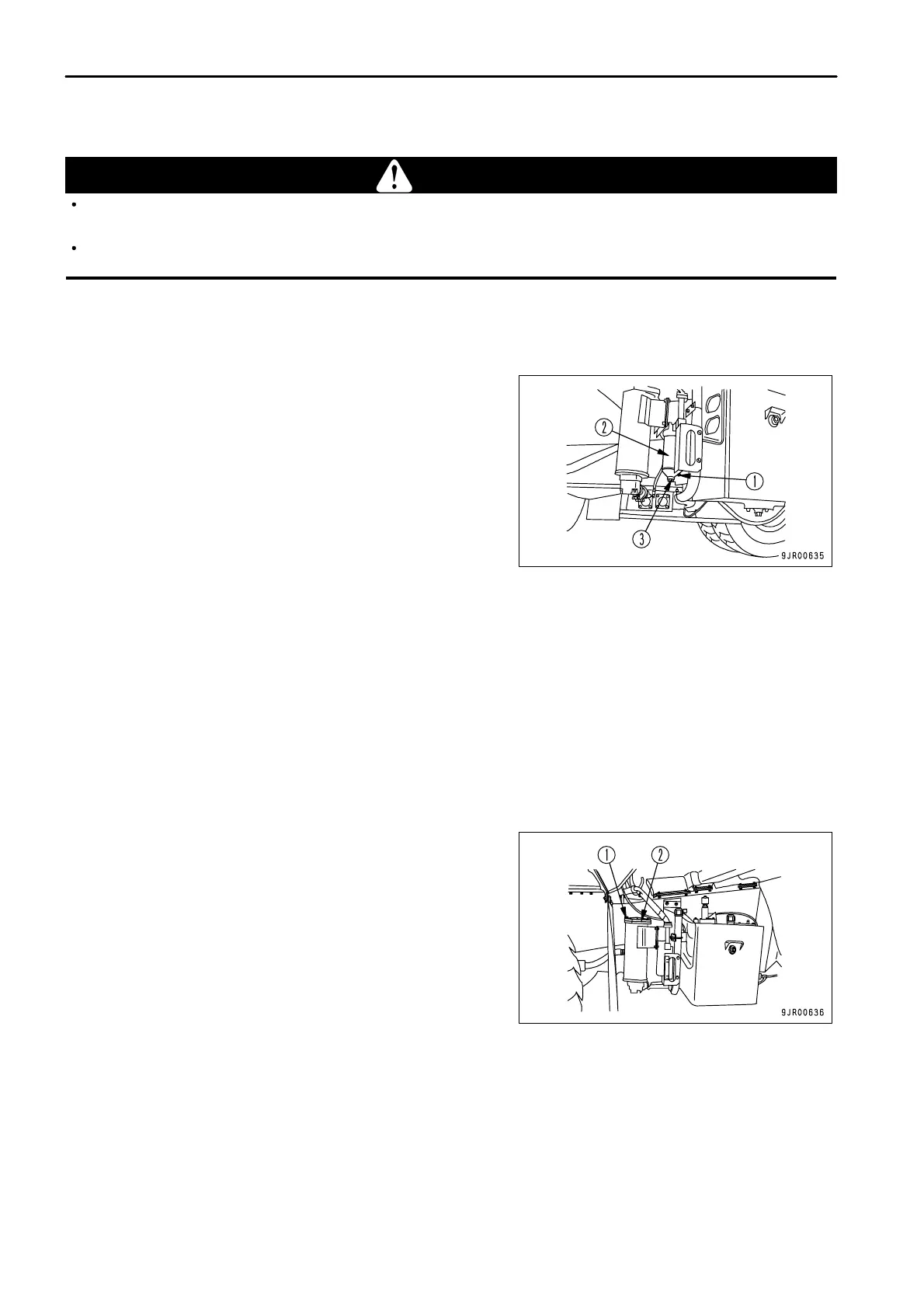

VALVE INLET SIDE

1.

Set the container to catch the oil under the filter case.

2.

Remove drain plug (1) at the bottom of the filter case, drain the

oil, then tighten the plug again.

3.

Hold down case (2), loosen center bolt (3), then remove case

(2).

4. Remove the element and clean the inside of the case.

5.

Replace the filter gasket and O-ring with new parts. Coat the

gasket and O-ring thinly with clean engine oil before installing.

6. Assemble the new element to the case, set the case in position, and install with center bolt (3).

Be careful not to tighten center bolt (3) too far.

Tightening torque: 167 to 196 Nm (17 to 20 kgm , 123 to 144.7 lbft)

7. Run the engine for a short time at idling, then stop the engine, and check that the oil is up to the specified level.

For details, see "CHANGE OIL IN TRANSMISSION CASE, CLEAN TRANSMISSION CASE STRAINER

(PAGE 4-65)".

Run the engine at high idling, and when the oil is warmed up, if the transmission filter (valve end) clogging

monitor lamp flashes, replace the element immediately.

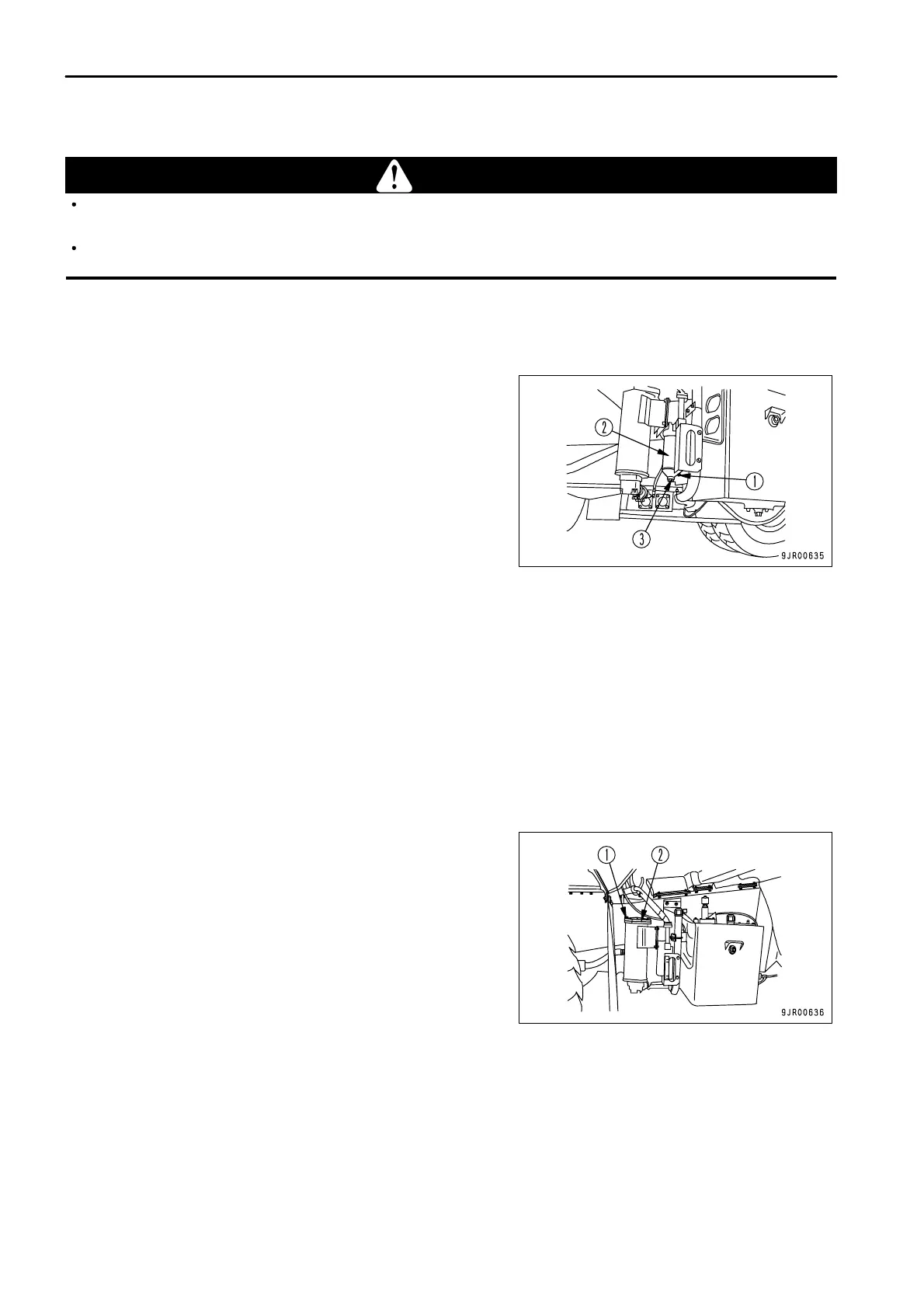

RETURN SIDE

1.

Remove bolt (1), then remove cover (2).

2. Take out the element, then clean the inside of the case and

removed parts.

3.

Install the new element, then install cover (2) with bolt (1).

Run the engine at high idling, and when the oil is warmed up, if the transmission filter (tank end) clogging monitor

lamp on the maintenance monitor (if equipped) flashes, replace the element immediately.

4 - 58

Loading...

Loading...