Assembly Procedure PC4000

PC4000Asrev05

Edition 08/2005

13

ã

• Wear safety clothing, goggles, respirator and other safety

devices, whenever working conditions make this necessary.

• Provide hoists of sufficient capacity to lift heavy units. Refer to

the weight specifications.

• Be sure to observe the instructions in the ”Assembly

Procedure Manual”.

• Lifting gear, tools and other suspension systems must be in

good condition and of sufficient lifting capacity.

• Be sure hydraulic cylinders and attachment components are

properly supported from hoist and securely fastened, before

removing supporting pins.

• Floors must be clean and dry. After draining operations be sure

all spillage is cleaned up.

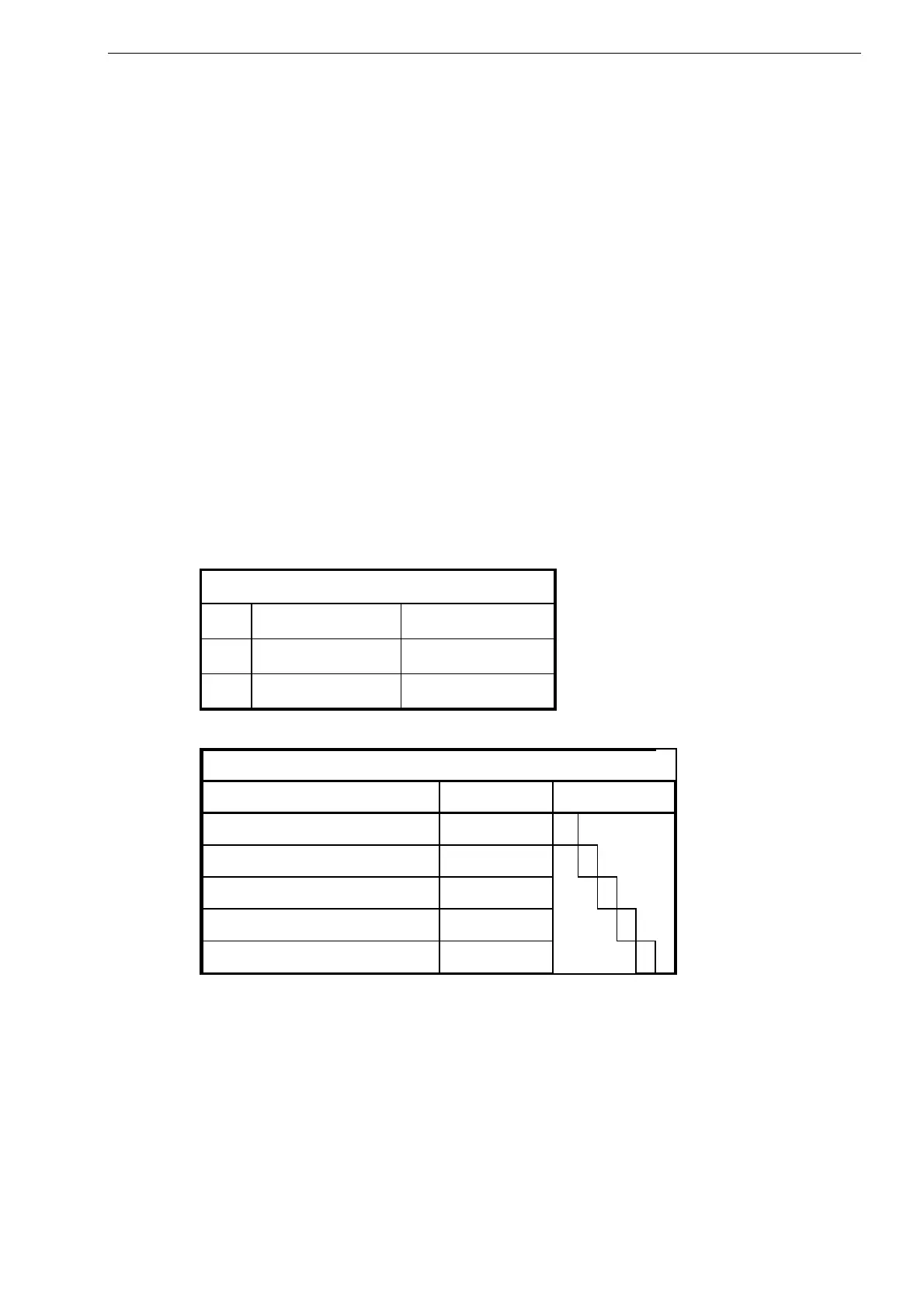

2.4 Manpower / Assembly Time

* Electric Drive Version 1 day longer

Schedule may change, depending on site preparation, man power, daily working hours and regulations.

Training time may vary, depending on knowledge and number of people.

Man Power

(10 hour shift)

1

Supervisor

KMG or Dealer

15 days

6

Customer

Mechanics

10 days

1 Operator Trainer

5 days

depending on demand

Time Schedule

Responsible

De

t.

Assembly

Service

8*

Setting and Test

Service

2

Customer Acceptance

Service

2

Operator Training

Techn. Support/

Application

5

Maintenance Training

Service

5

10 Hours Day