B1700'B21 00·B2400 WSM, 11770

1

ENGINE

ST10F040

Connecting

Rod

Alignment

III

NOTE

..

Since

the I.D.

of

the connecting rod small end bushing

is

the

basis

of

this check, check the bushing

for

wear beforehand.

1.

Install the piston pin into the connecting rod.

2.

Install the connecting rod on the connecting rod alignment

tool

(Code

No:

07909-31661).

3.

Put a gauge over the piston pin and move

it

against

the

face

plate.

4.

If

the gauge does not

fit

squarely against

the

face plate,

measure the

space

between the pin

of

the gauge and

the

face plate.

5.

If

the measurement

exceeds

the allowable limit, replace

the

connecting rod.

(4) Crankshaft

connecting rod

alignment

Allowable

limit

0.05

mm

0.0020 in.

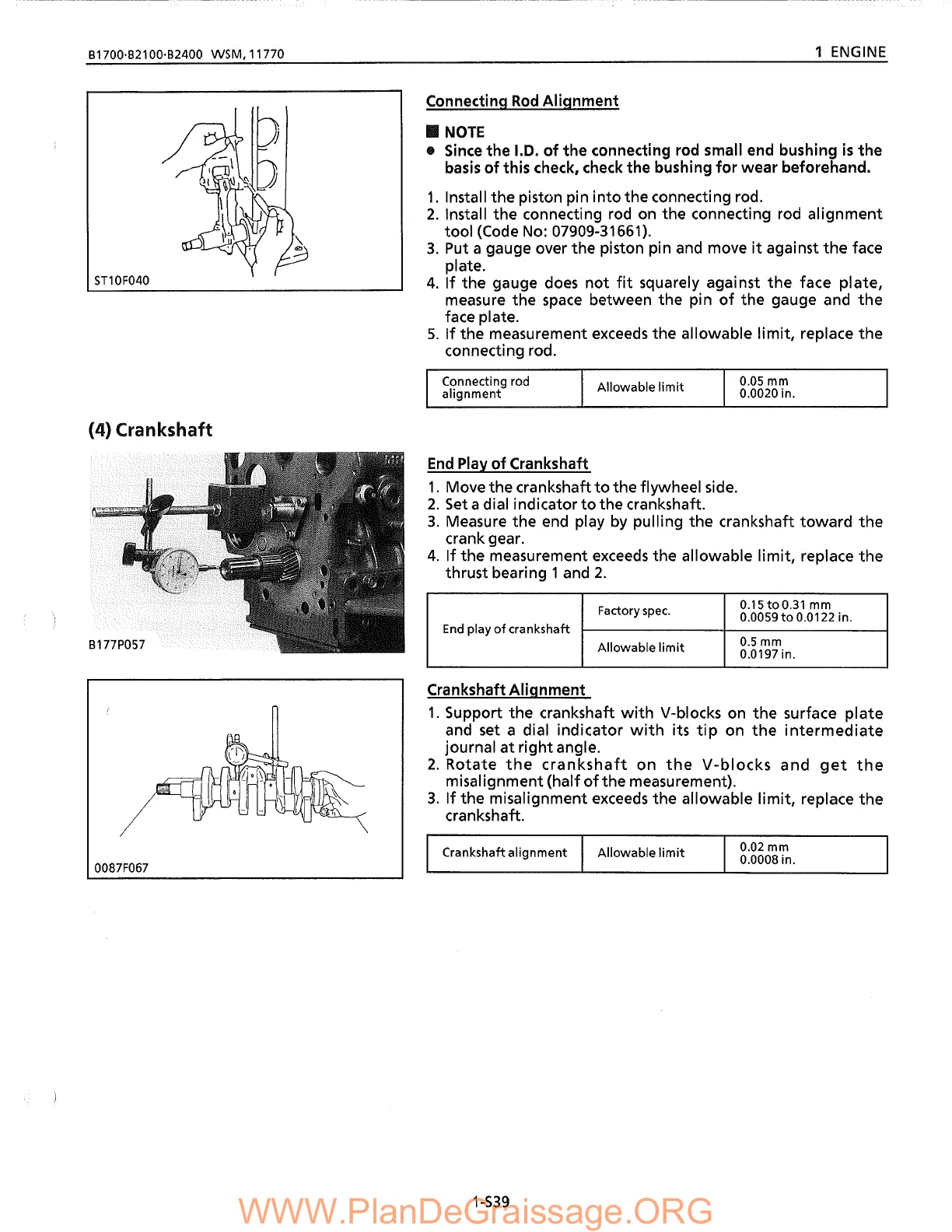

End

Play

of

Crankshaft

1.

Move the crankshaft

to

the flywheel side.

2.

Set

a dial indicator

to

the crankshaft.

3.

Measure the end play

by

pulling the crankshaft

toward

the

crank gear.

4.

If

the measurement

exceeds

the allowable limit, replace

the

thrust bearing 1and

2.

Factory

spec.

0.15toO.31 mm

0.0059

to

0.0122 in.

End

play

of

crankshaft

Allowable

limit

0.5mm

0.0197 in.

Crankshaft Alignment

1.

Support the crankshaft

with

V-blocks on

the

surface plate

and set a dial indicator

with

its

tip

on

the

intermediate

journal

at

right angle.

2.

Rotate

the

crankshaft

on

the

V-blocks

and

get

the

misalignment (half

ofthe

measurement).

3.

If

the misalignment

exceeds

the allowable limit, replace

the

crankshaft.

0087F067

Crankshaft alignment

1-S39

Allowable

limit

0.02 mm

0.0008 in.

Loading...

Loading...