2

CLUTCH

81700·82100·82400 WSM,11770

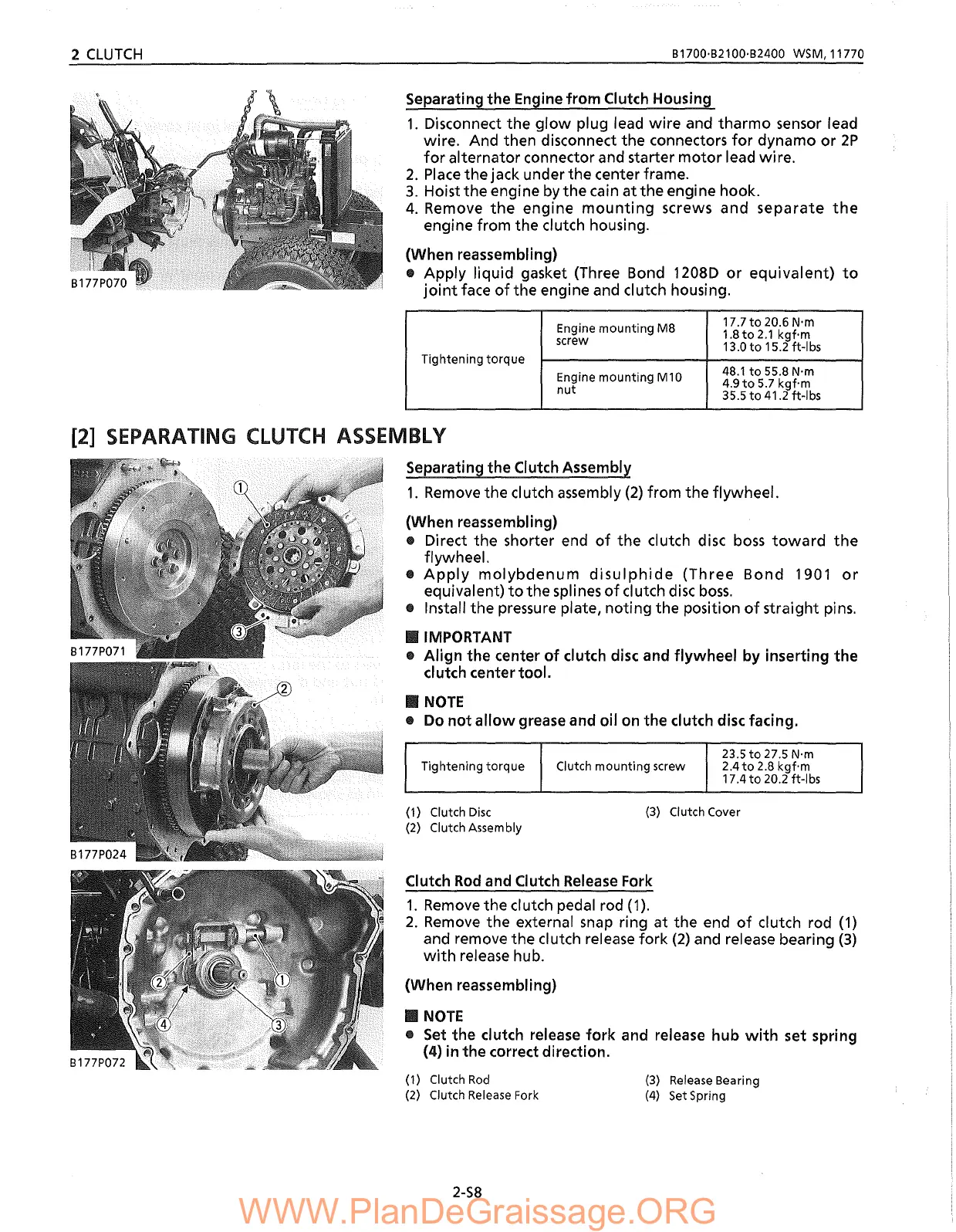

separating the Engine from Clutch Housing

1.

Disconnect the

glow

plug lead wire and tharmo sensor lead

wire. And then disconnect the connectors

for

dynamo

or

2P

for

alternator connector and starter

motor

lead wire.

2.

Place

the jack under the center frame.

3. Hoist the engine

by

the cain at the engine hook.

4.

Remove

the

engine

mounting

screws and separate

the

engine from the clutch housing.

(When reassembling)

.. Apply liquid gasket (Three Bond 1208D

or

equivalent)

to

joint

face

of

the engine and clutch housing.

Engine mounting M8

17.7

to

20.6 N'm

1.8

to

2.1

kgf'm

screw

13.0

to

15.2 ft-Ibs

Tightening torque

Engine mounting M10

48.1

to

55.8 N'm

4.9

to

5.7

kgf'm

nut

35.5

to

41.2 ft-Ibs

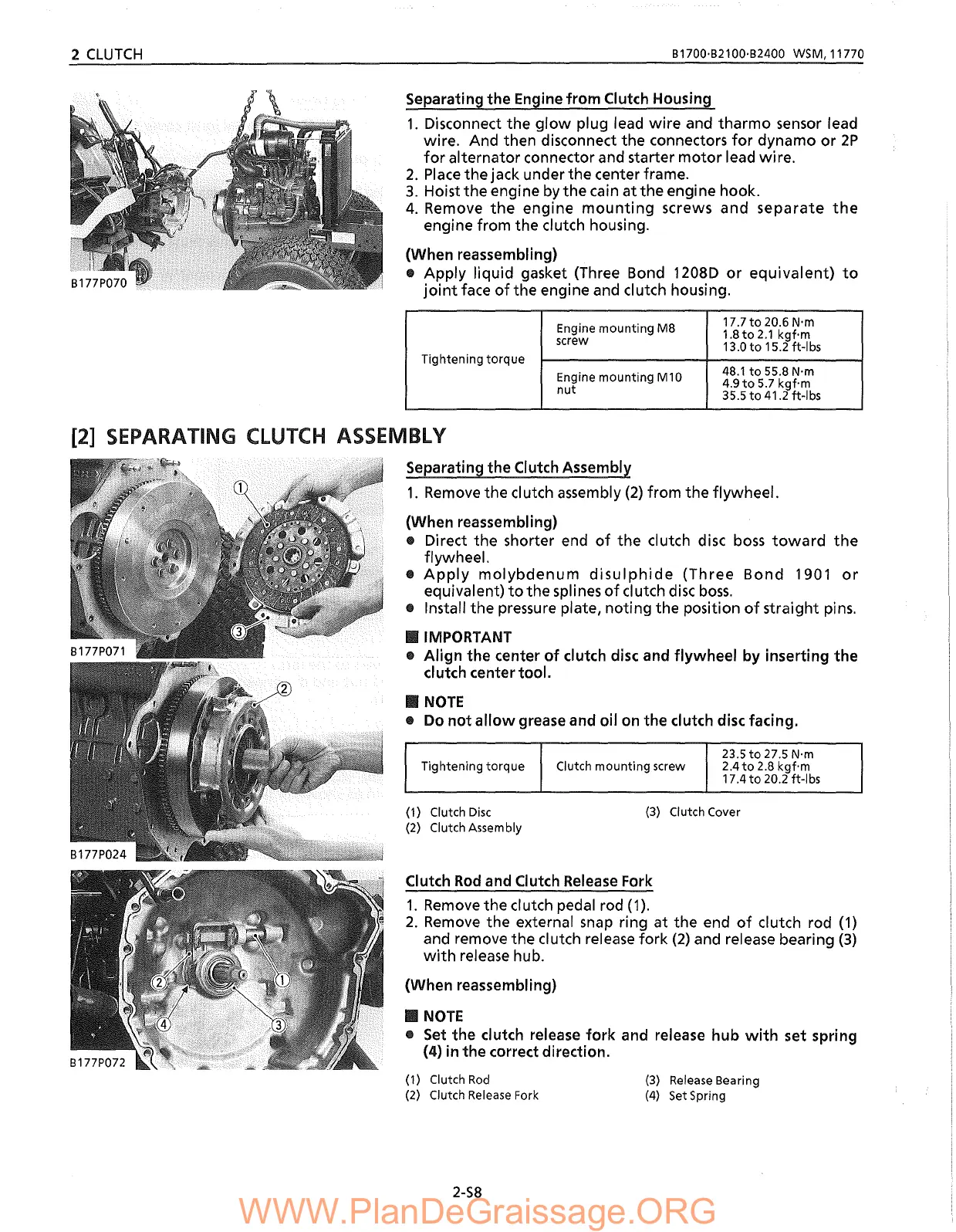

_

NOTE

• Do

not

allow

grease and oil on the clutch disc facing.

23.5

to

27.5 N'm

Tightening

torque

Clutch mounting screw

2.4

to

2.8

kgf'm

17.4

to

20.2 ft-Ibs

Clutch

Rod

and Clutch

Release

Fork

1.

Remove

the clutch pedal rod

(1).

2.

Remove

the external

snap

ring at the end

of

clutch rod

(1)

and remove the clutch release

fork

(2)

and release bearing (3)

with

release hub.

(When reassembling)

_

NOTE

•

Set

the clutch release

fork

and release hub

with

set spring

(4) in the correct direction.

(3)

Clutch Cover

(1) Clutch

Disc

(2)

Clutch Assembly

[2] SEPARATING CLUTCH ASSEMBLY

separating the Clutch Assembly

1.

Remove

the clutch assembly

(2)

from the flywheel.

(When reassembling)

.. Direct the shorter end

of

the clutch disc

boss

toward

the

flywheel.

•

Apply

molybdenum

disulphide

(Three

Bond

1901

or

equivalent)

to

the splines

of

clutch

disc

boss

.

.. Install the pressure plate, noting the position

of

straight pins.

_IMPORTANT

• Align the center

of

clutch disc and flywheel by inserting the

clutch center tool.

(1) Clutch

Rod

(2)

Clutch

Release

Fork

(3)

Release

8earing

(4)

Set

Spring

2-58

Loading...

Loading...