1-S56

GL6000, GL7000, GL9000, GL11000, WSM

ENGINE

Oil Clearance between Crankshaft Journal and Crankshaft

Bearing 2 and Crankshaft Bearing 3

1. Put a strip of plastigauge (Code No. 07909-30241) on the center

of the journal.

2. Install the bearing case and tighten the bearing case screws 1 to

the specified torque, and remove the bearing case again.

3. Measure the amount of the flattening with the scale, and get the

oil clearance.

4. If the oil clearance exceeds the allowable limit, replace the

crankshaft bearing 2 (crankshaft bearing 3).

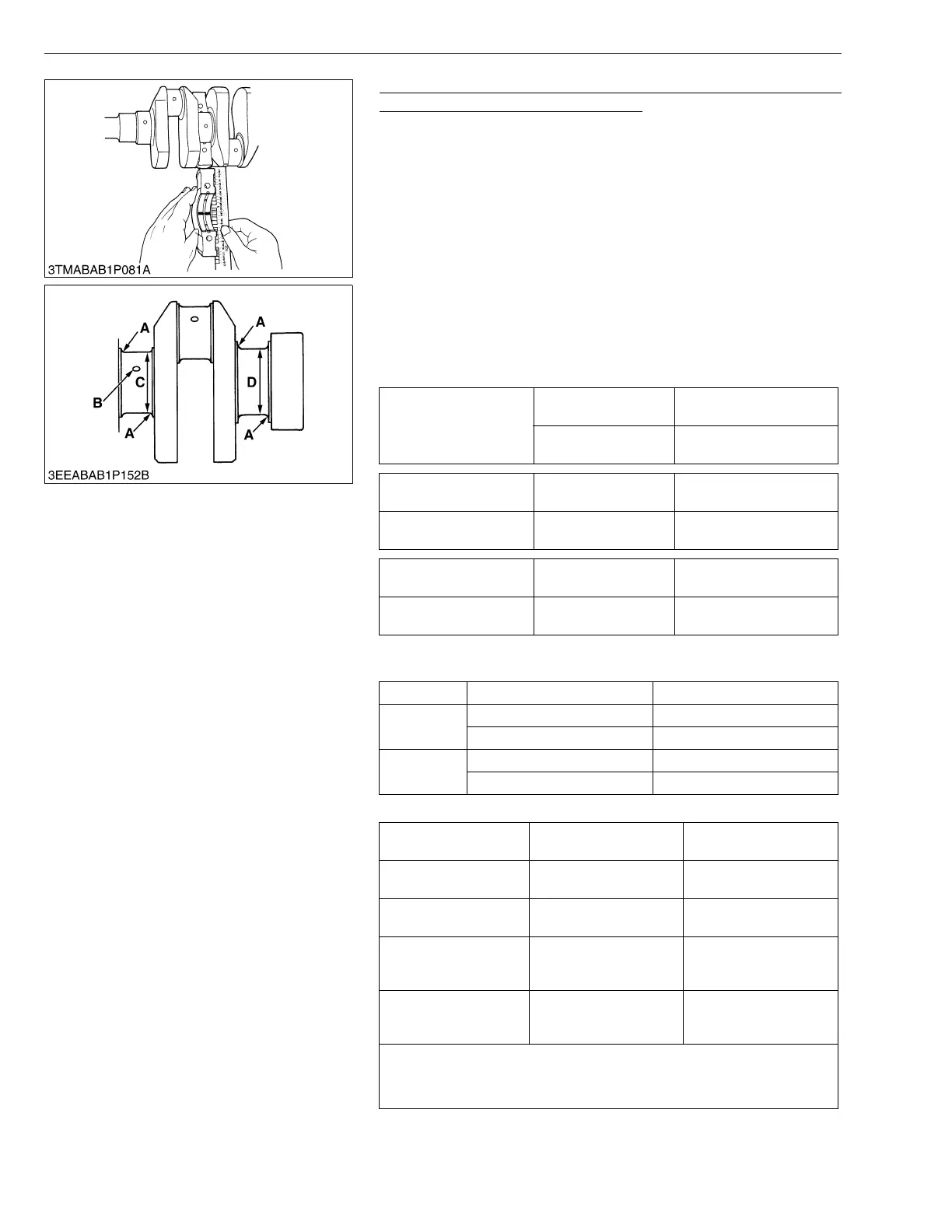

5. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an undersize one referring to the

table and figure.

• Be sure not to move the crankshaft while the bearing case

screws are tightened.

(Reference)

• Undersize crankshaft bearing 2 and 3

• Undersize dimensions of crankshaft journal

W10344030

Oil clearance between

crankshaft journal and

crankshaft bearing 2

(crankshaft bearing 3)

Factory spec.

0.028 to 0.059 mm

0.00110 to 0.00232 in.

Allowable limit

0.20 mm

0.0079 in.

Crankshaft journal O.D.

(Flywheel side)

Factory spec.

43.934 to 43.950 mm

1.72968 to 1.73031 in.

Crankshaft bearing 2

I.D.

Factory spec.

43.978 to 43.993 mm

1.73142 to 1.73201 in.

Crankshaft journal O.D.

(Intermediate)

Factory spec.

39.934 to 39.950 mm

1.57221 to 1.57284 in.

Crankshaft bearing 3 I.D. Factory spec.

39.978 to 39.993 mm

1.57394 to 1.57453 in.

Oversize Part Name Marking

0.2 mm

0.008 in.

Crankshaft bearing 2 02 020 US

Crankshaft bearing 3 02 020 OS

0.4 mm

0.016 in.

Crankshaft bearing 2 04 040 OS

Crankshaft bearing 3 04 040 OS

Undersize

0.2 mm

0.008 in.

0.4 mm

0.016 in.

Dimension A

1.8 to 2.2 mm radius

0.071 to 0.087 in. radius

1.8 to 2.2 mm radius

0.071 to 0.087 in. radius

*Dimension B

1.0 to 1.5 mm relief

0.0394 to 0.0591 in. relief

1.0 to 1.5 mm relief

0.0394 to 0.0591 in. relief

Dimension C

39.734 to 39.750 mm dia.

1.56433 to 1.56496 in.

dia.

39.534 to 39.550 mm dia.

1.55646 to 1.55709 in.

dia.

Dimension D

43.734 to 43.750 mm dia.

1.72181 to 1.72244 in.

dia.

43.534 to 43.550 mm dia.

1.71394 to 1.7147 in. dia.

(0.8S)

The crankshaft journal must be fine-finished to higher than .

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.0394 to 0.0591 in.) relief.

Loading...

Loading...