2-S9

GL6000, GL7000, GL9000, GL11000, WSM

GENERATOR

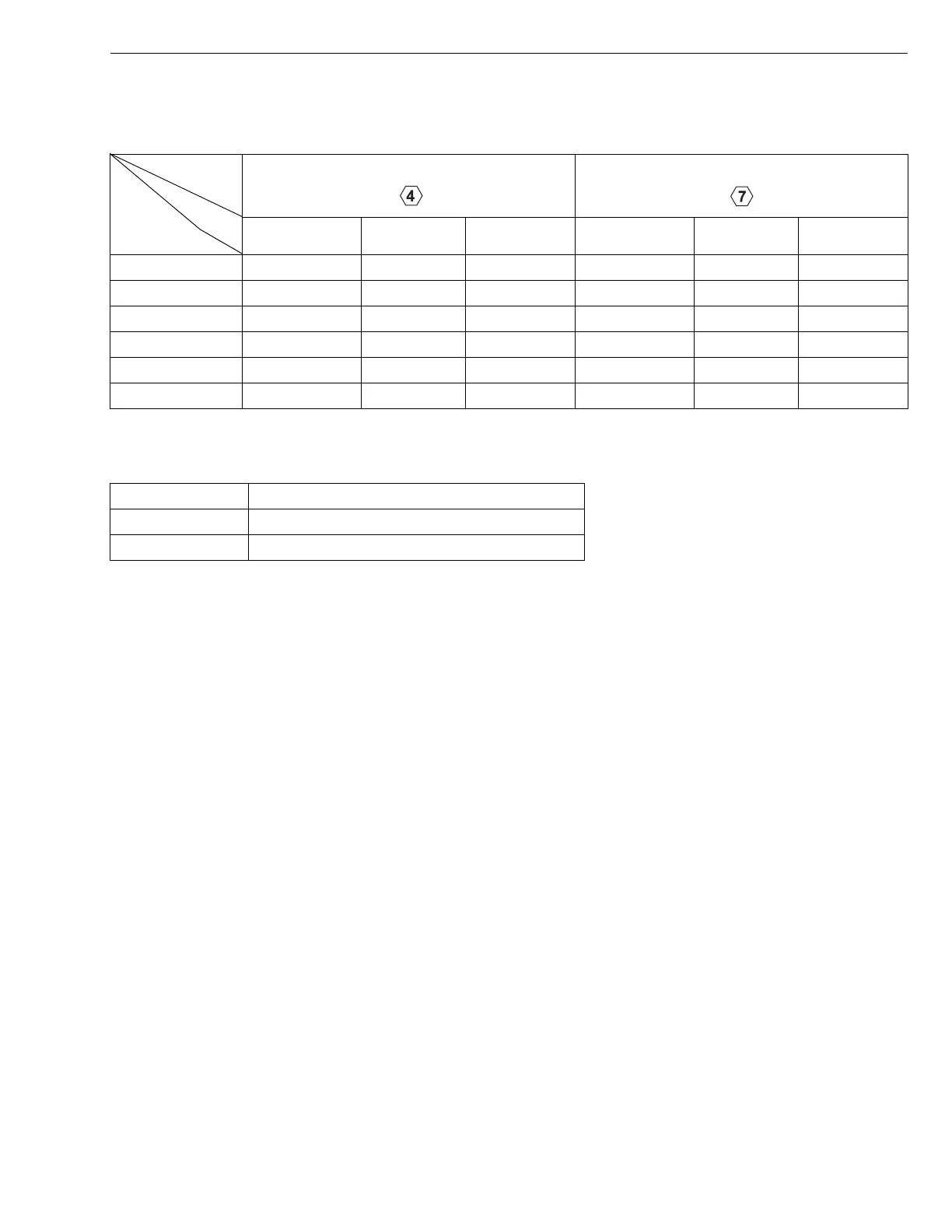

[2] TIGHTENING TORQUES FOR GENERAL USE SCREWS, BOLTS AND

NUT

When the tightening torques are not specified, tighten the screws, bolts and nuts according to the table below.

W10371750

Screw and bolt material grades are shown by numbers punched on the screw and bolt heads. Prior to

tightening, be sure to check out the numbers as shown below.

W1012705

Grade

Nominal Unit

Diameter

Standard Screw and Bolt

Special Screw and Bolt

N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M4 1.0 to 2.9 0.1 to 0.3 0.7 to 2.1 – – –

M5 1.9 to 3.6 0.2 to 0.4 1.4 to 2.7 – – –

M6 7.9 to 9.3 0.80 to 0.95 5.8 to 6.9 9.8 to 11.3 1.00 to 1.15 7.23 to 8.32

M8 17.7 to 20.6 1.8 to 2.1 13.0 to 15.2 23.5 to 27.5 2.4 to 2.8 17.4 to 20.3

M10 39.2 to 45.1 4.0 to 4.6 28.9 to 33.3 48.1 to 55.9 4.9 to 5.7 35.4 to 41.2

M12 62.8 to 72.6 6.4 to 7.4 46.3 to 53.5 77.5 to 90.2 7.9 to 9.2 57.1 to 66.5

Punched number Screw and bolt material grade

None or 4 Standard screw and bolt SS41, S20C

7 Special screw and bolt S43C, S48C (Refined)