10. Fill with 20W50 motor oil until oil just appears at the

bottom of the oil level check port. Install the oil level

check port plug (9) into transaxle. Torque the plug

(9) to 20.34 N⋅m (15.0 lbf⋅ft).

11. Install the metal fitting assembly (5) to the transaxle

(1) and torque the metal fitting assembly (5) to

20.34 N⋅m (15.0 lbf⋅ft). Then install the barbed cap

(6) and the hose (7).

12. Proceed to the purge procedure.

2. Changing transaxle fluid

(See Replacing transaxle filter (T2290KWT) on page

59.)

EVERY 1 YEAR

1. Checking fuel line

WARNING

To avoid serious injury or death:

• Be sure to stop the engine and remove the key

when attempting to make the following checks

and changes.

• Never fail to check the fuel lines periodically.

The fuel lines are subject to wear and aging.

Fuel may leak out onto the running engine,

causing a fire.

The fuel line is made of rubber and ages regardless of

service period.

1. If the fuel line and clamps are found damaged or

deteriorated, replace them.

IMPORTANT :

• When the fuel line is disconnected for

maintenance or repair, close both ends of

the fuel line with a piece of clean cloth or

paper to prevent dust and dirt from entering.

In addition, particular care must be taken not

to admit dust and dirt into the fuel pump.

Entrance of dust and dirt causes

malfunction of the fuel pump.

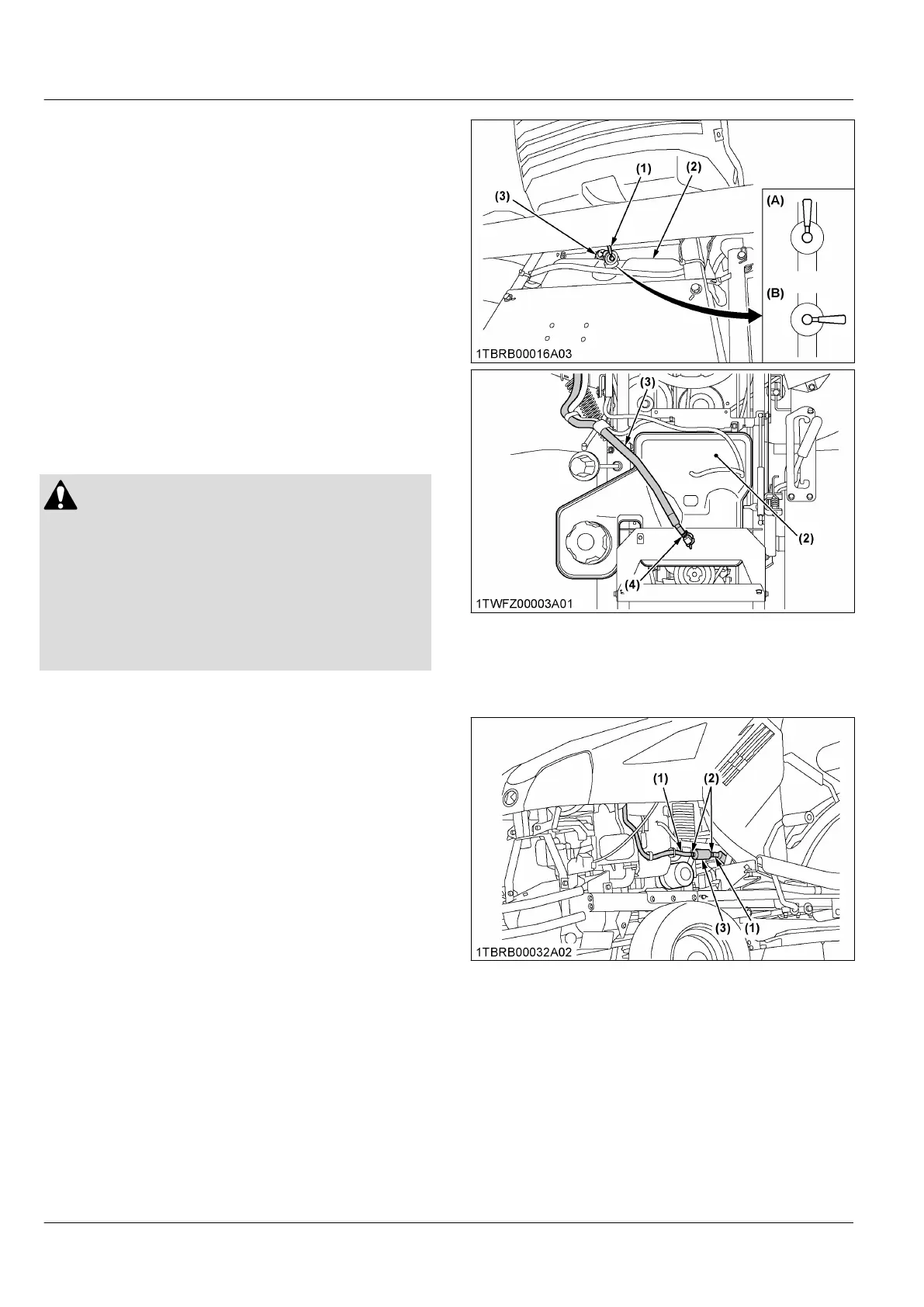

(1) Fuel valve

(2) Fuel tank

(3) Fuel line

(4) Pipe clamps

(A) “OPEN”

(B) “CLOSE”

T2090BR

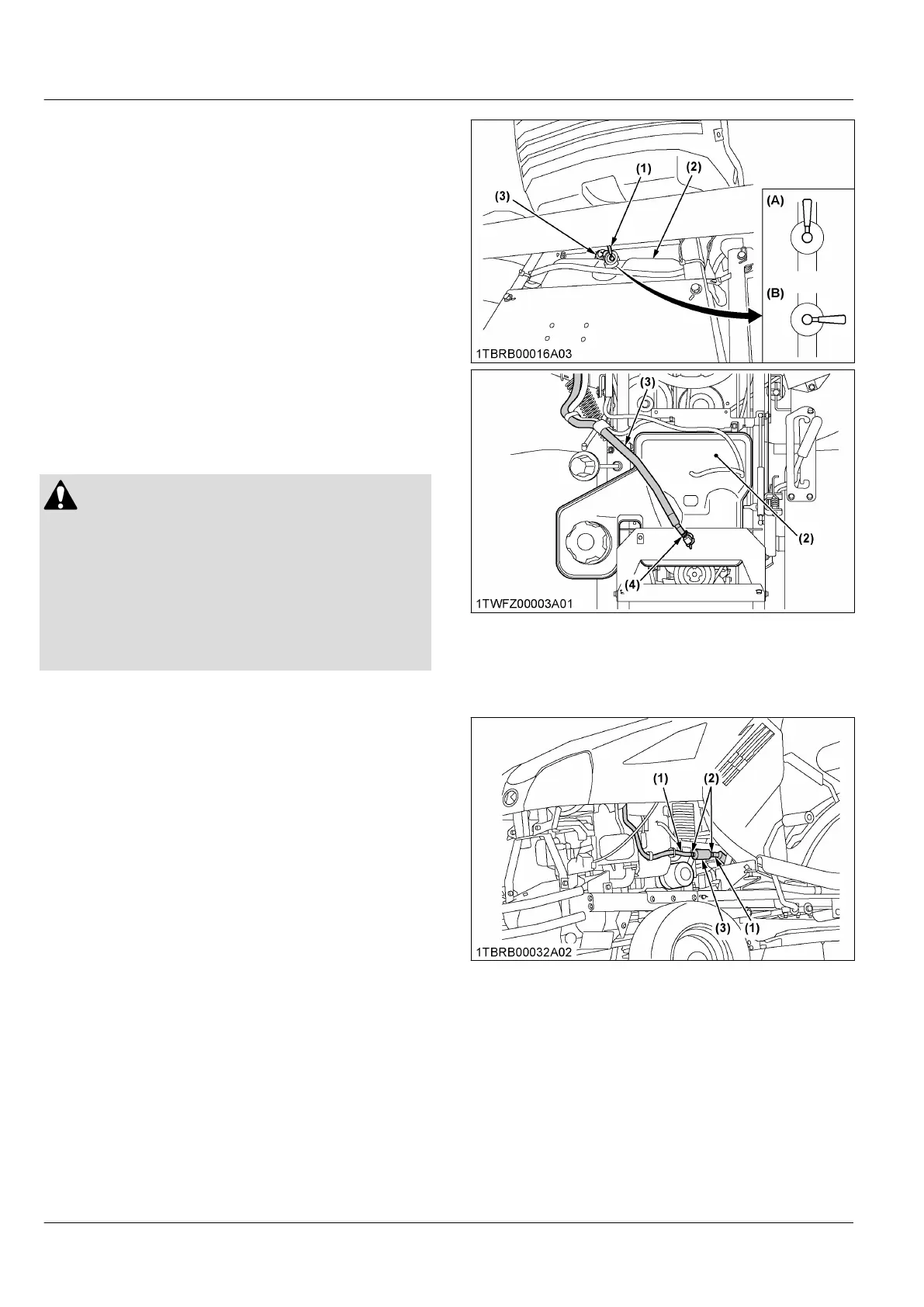

(1) Fuel hose

(2) Fuel hose clamp

(3) Fuel filter

PERIODIC SERVICE EVERY 600 HOURS

T2090BR-AU,T2290KW-AU,T2290KWT-AU

Loading...

Loading...