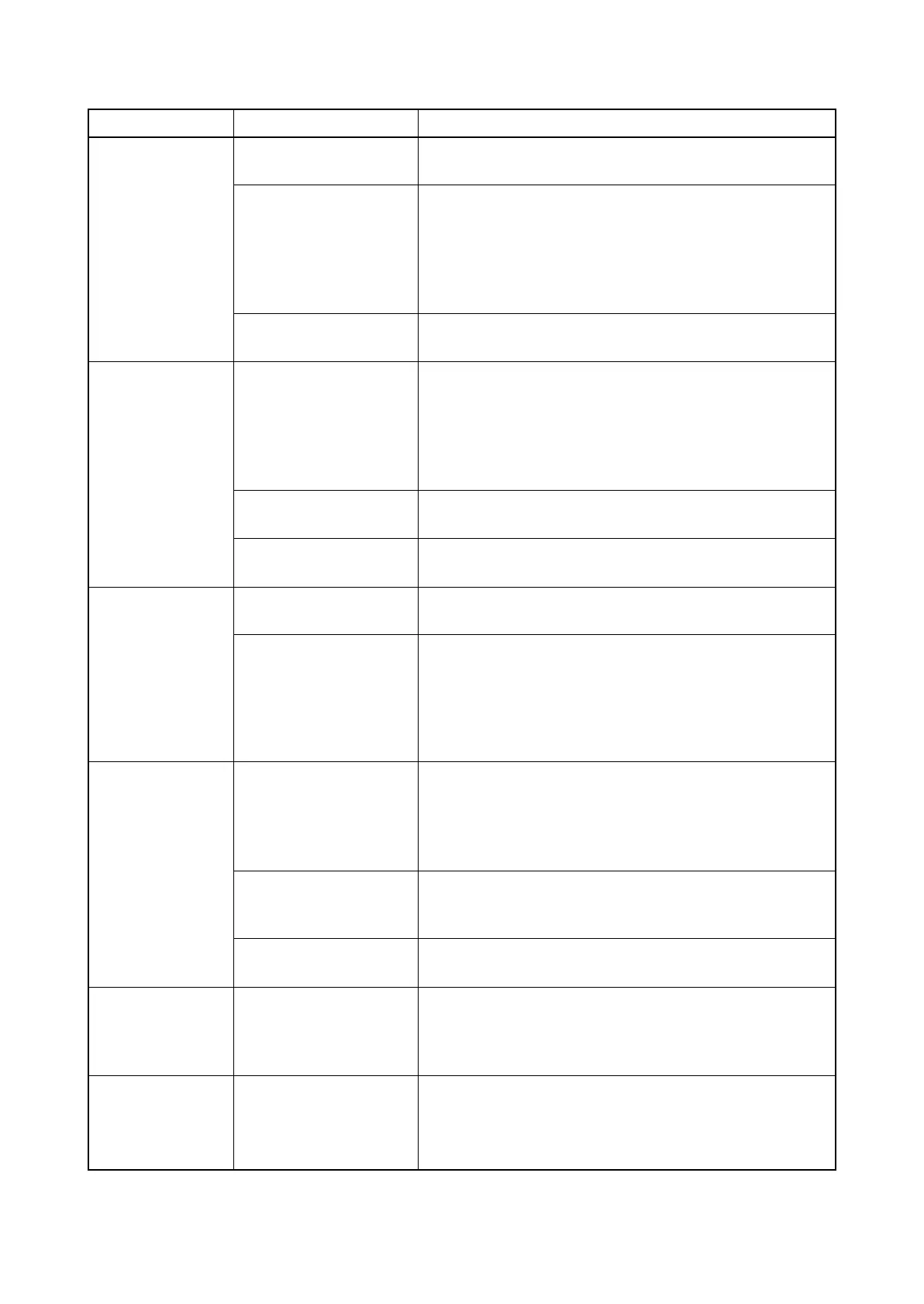

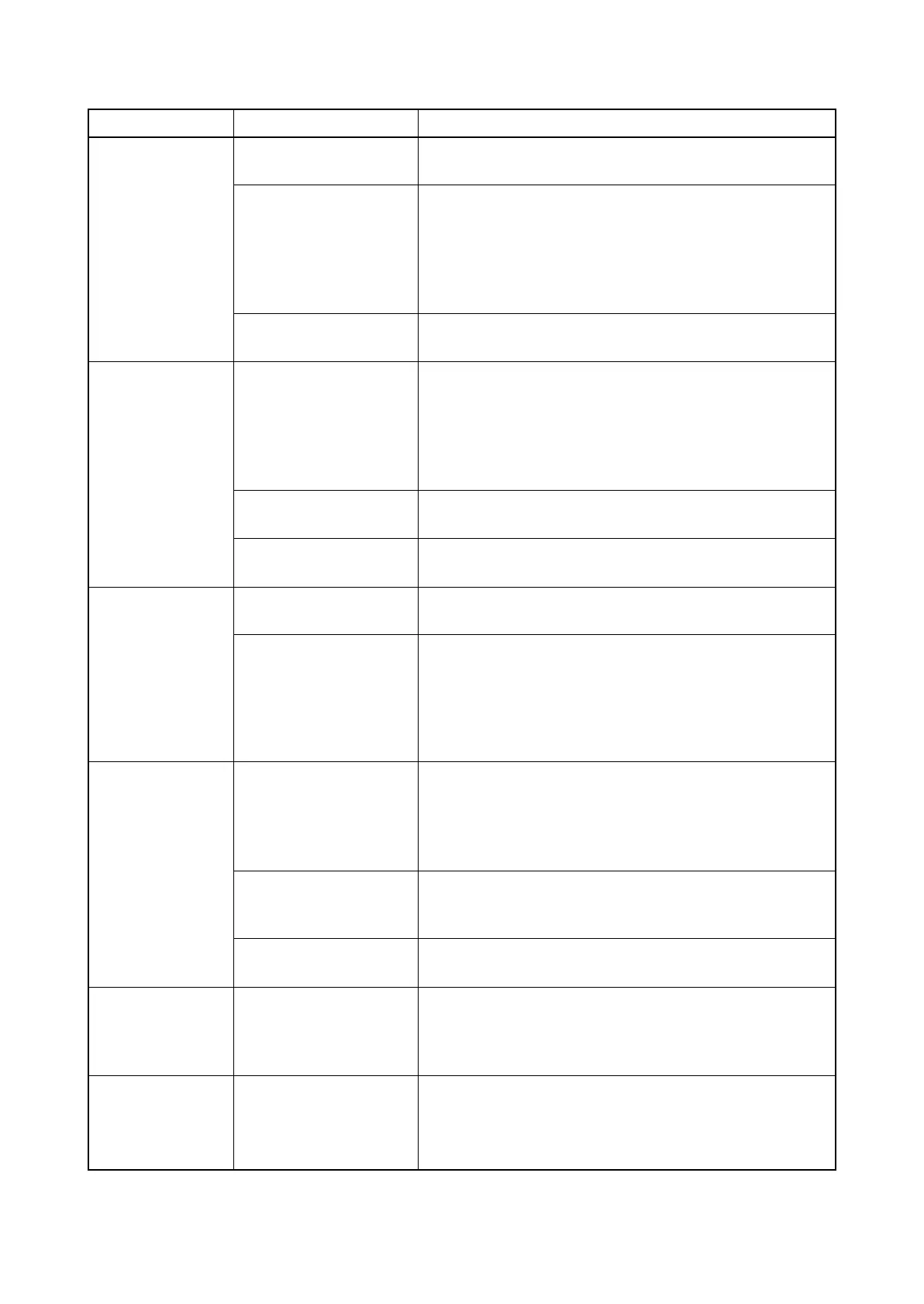

2PK/2PL/2PM/2PN

1-4-25

(8)Duplex solenoid

does not operate.

1. Broken duplex sole-

noid coil.

Check for continuity across the coil. If none, replace the

duplex solenoid.

2. Defective harness

between duplex sole-

noid and control

PWB (YC29), or

improper connector

insertion.

Reinsert the connector. Also check for continuity within the

connector harness. If none, remedy or replace the harness.

3. Defective control

PWB.

Replace the control PWB (See page 1-5-37).

(9)Cleaning lamp

does not turn on.

1. Defective harness

between cleaning

lamp (YC701) and

control PWB (YC28),

or improper connec-

tor insertion.

Reinsert the connector. Also check for continuity within the

connector harness. If none, remedy or replace the harness.

2. Defective cleaning

lamp (PWB).

Replace the cleaning lamp (PWB).

3. Defective control

PWB.

Replace the control PWB (See page 1-5-37).

(10)Paper indica-

tor is flashing when

paper is present in

the cassette.

1. Defective paper sen-

sor.

Replace the paper sensor.

2. Defective harness

between paper sen-

sor and control PWB

(YC18), or improper

connector insertion.

Reinsert the connector. Also check for continuity within the

connector harness. If none, remedy or replace the harness.

(11)A paper jam in

the paper feed/

conveying section

or fuser section is

indicated when the

main power switch

is turned on.

1. A piece of paper torn

from paper is caught

around registration

sensor or exit sen-

sor.

Check and remove if any.

2. Defective registration

sensor on the high

voltage PWB.

Replace the high voltage PWB (See page 1-5-43).

3. Defective exit sen-

sor.

Replace the exit sensor.

(12)Attention indi-

cator is lit when the

front cover is

closed.

1. Defective interlock

switch on the power

source PWB.

Check for continuity across the interlock switch. If there is

no continuity when the interlock switch is on, replace the

power source PWB (See page 1-5-40).

(13)When the trou-

ble occurs in the

DP.

-

Refer to the DP’s service manual.

Problem Causes Check procedures/corrective measures

Loading...

Loading...