Handling Paper 3-7

Whiteness: The contrast of the printed page depends on the whiteness

of the paper. Whiter paper provides a sharper, brighter appearance.

Quality control: Uneven sheet size, corners that are not square, ragged

edges, welded (uncut) sheets, and crushed edges and corners can cause

the machine to malfunction in various ways. A quality paper supplier

should take considerable care to ensure that these problems do not

occur.

Packaging: Paper should be packed in a sturdy carton to protect it from

damage during transport. Quality paper obtained from a reputable

supplier is usually correctly packaged.

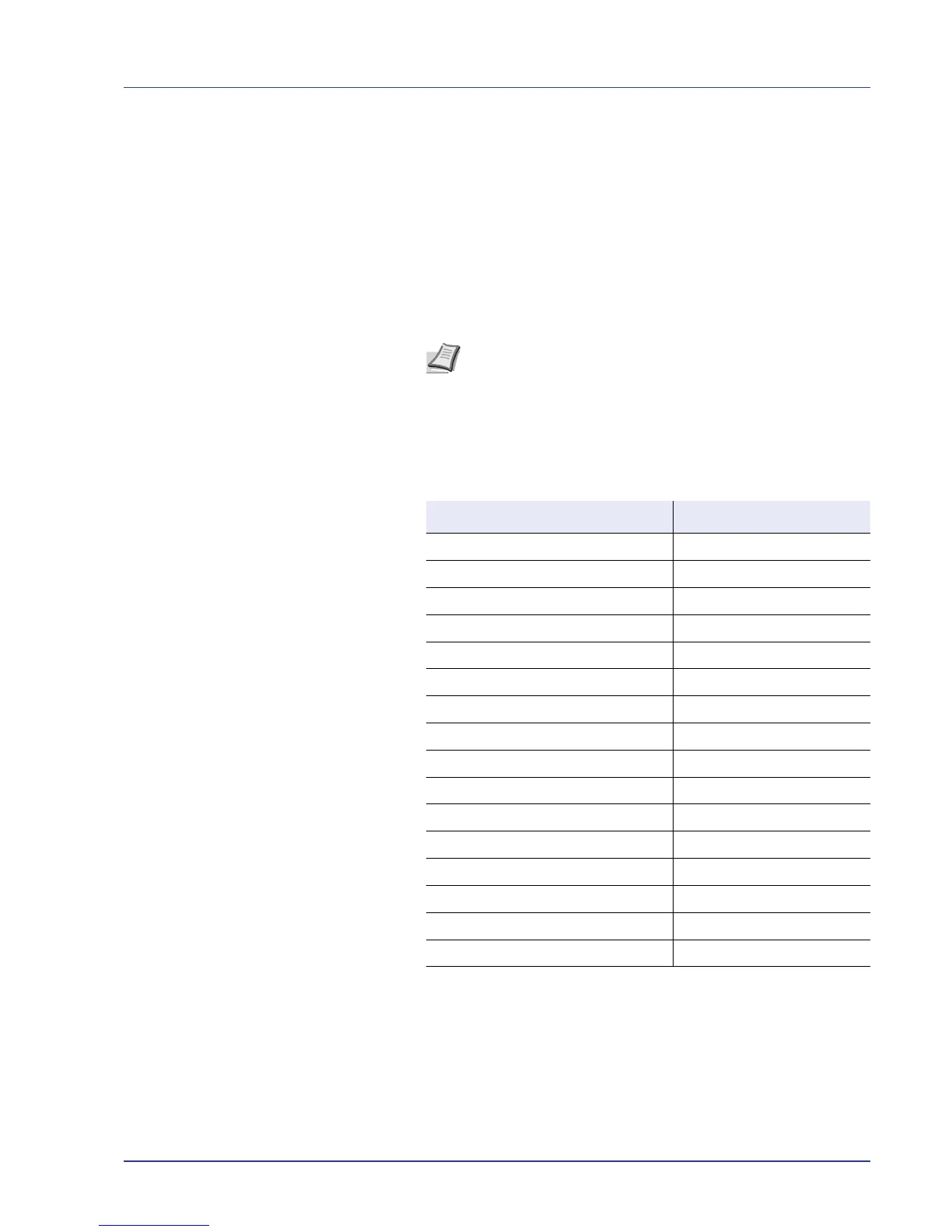

Special Paper

The following types of special paper can be used:

Use paper that is sold specifically for use with copiers or printers (heat-

fusing type). When using transparencies, labels, thin paper, envelopes,

postcards, or thick paper, feed the paper from the MP tray. For details,

refer to Paper Settings on page 4-46.

Since the composition and quality of special paper vary considerably,

special paper is more likely than white bond paper to give trouble during

Note You might see the printer emitting steam in the area around

the top tray if you use damp paper, but it is safe to continue

printing.

Paper Type to be Used Paper Type to be Selected

Overhead projector transparencies TRANSPARENCY

Rough paper ROUGH

Thin paper (60 to 64 g/m²) VELLUM

Label LABELS

Recycled paper RECYCLED

Preprinted paper PREPRINTED

Bond paper BOND

Postcards CARDSTOCK

Colored paper COLOR

Prepunched paper PREPUNCHED

Letterhead LETTERHEAD

Envelopes ENVELOPE

Coated paper COATED

Thick paper (120 to 220 g/m²) THICK

High-quality paper HIGH QUALITY

Custom CUSTOM 1~8

Loading...

Loading...