Page 13

TABLE 5

G26 BLOWER RATINGS 120V 1PH

BLOWER MOTOR HP

G26Q3

CAP

1/3

5MFD 370V

G26Q4/5

G26Q3/4

1/2

7.5MFD 370V

3/4 40MFD 370V

G26Q2

1/5

5MFD 370V

8-Combustion Air Blower (B6)

All G26 units use a combustion air blower to move air

through the burners and heat exchanger during heating opĆ

eration. The blower uses a PSC or shaded Pole 120VAC

motor. PSC motors use run capacitors. The motor operates

during all heating operation and is controlled by blower conĆ

trol A15. The blower operates continuously while there is a

call for heat. The ignition control is prevented from proceedĆ

ing through the ignition sequence until combustion air blower

operation is sensed by the prove switch.

The pressure switch connected to the combustion air blower

housing is used to prove combustion air blower operation.

The switch monitors air pressure in the blower housing. DurĆ

ing normal operation, the pressure in the housing is negaĆ

tive. If the pressure drops (becomes more positive), the

pressure switch opens. When the pressure switch opens,

the ignition control (A3) immediately closes the gas valve to

prevent burner operation.

9-Primary Limit Control (S10)

The primary limit (S10) on G26 units is located in the

middle of the heating vestibule panel. When excess heat

is sensed in the heat exchanger, the limit will open. If the

limit is tripped, the furnace control energizes the supply air

blower and de-energizes the gas valve. The limit automatiĆ

cally resets when unit temperature returns to normal. The

switch is factory set and cannot be adjusted. The switch

may have a different setpoint for each unit model numĆ

ber. However, the setpoint will be printed on the side of

the limit.

FIGURE 13

INSULATING COVER (s)

LIMIT CONTROL (S10) FOR

G26 SERIES UNITS AND ALTERNATE STYLE

SPADE CONNECTORS

LIMIT

Units may be equipped with either style limit.

10-Rollout Switch (S47) -3 Through -6

Flame rollout switch S47 is a SPST N.C. high temperature

limit located on the right side of the burner box assembly (see

figure 14). S47 is wired to the burner ignition control A3.

When S47 senses flame rollout (indicating a blockage

in the combustion passages), the flame rollout switch

trips, and the ignition control immediately closes the

gas valve.

Switch S47 in all G26 units is factory preset to open at

200F + 12F (93C + 6.7C) on a temperature rise. All

flame rollout switches are manually reset. A kit (#65K60) is

available for G26 -1 and -2 models.

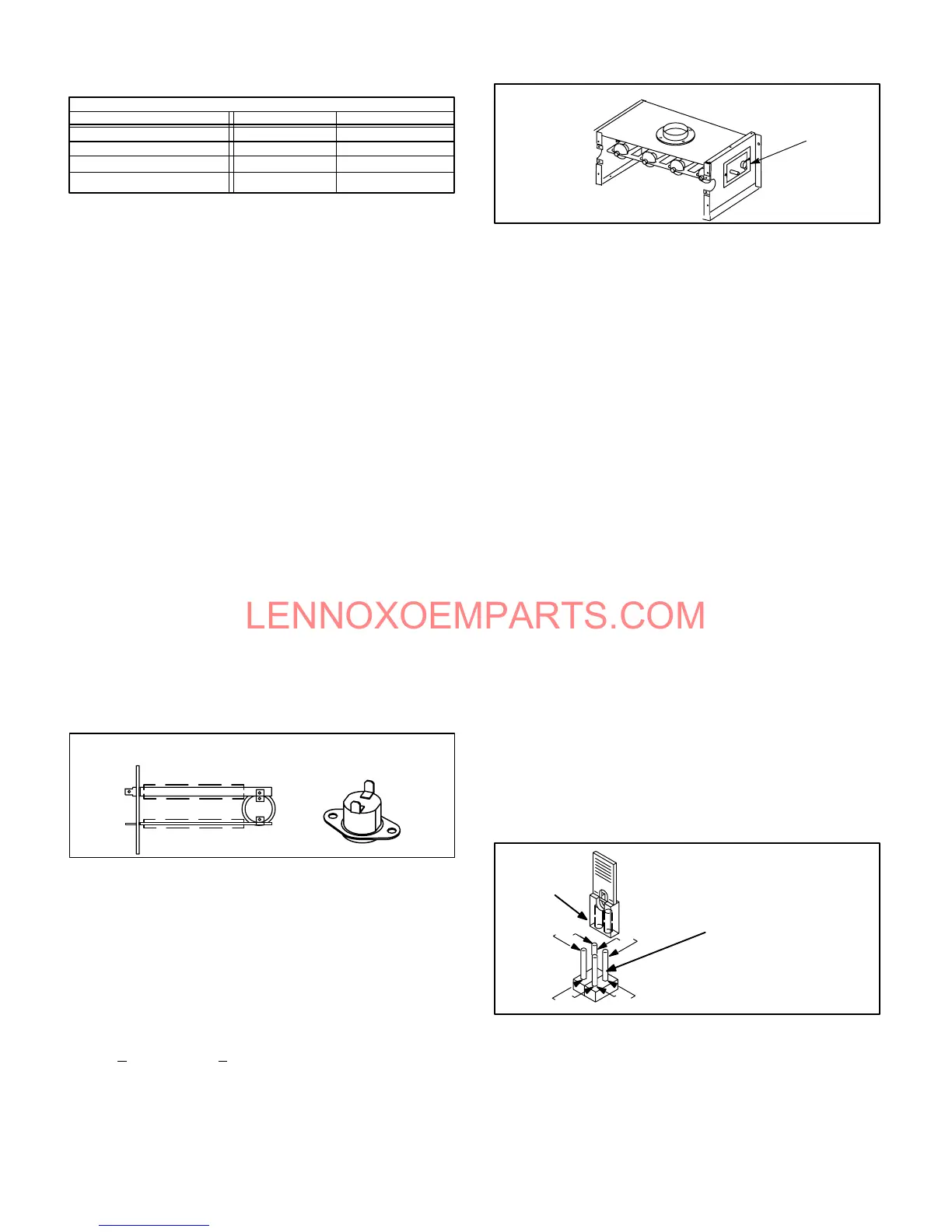

FI

RE 14

FLAME ROLLOUT SWITCH (S47)

FLAME ROLLOUT

SWITCH (S47)

11- BCC2-3 Blower Control A15

(-1 and -2 models)

All G26-2 and -1 model units utilize the BCC2Ć3 blower conĆ

trol manufactured by Heatcraft. The BCC2Ć3 is a printed cirĆ

cuit board which controls the supply air blower and monitors

primary limit and gas valve operation. The control has a

nonĆadjustable, factory preset fanĆon" timing. Fan off" timĆ

ing is adjustable. The board is divided into two sections,

120 and 24VAC. Line voltage comes into the board on the

120VAC side. See figure 16.

Fan Timings

Fan off" timing (time that the blower operates after the heat

demand has been satisfied) is determined by the arrangeĆ

ment of a jumper across pins on the BCC2Ć3 blower control

board. See figure 15. To adjust fan off " timing, gently disĆ

connect jumper and reposition across pins corresponding

with new timing. Fan on" time is factory set at 45 seconds

and is not adjustable.

NOTEĊIf fan off" time is set too low, residual heat in

heat exchanger may cause primary limit S10 to trip reĆ

sulting in frequent cycling of blower. If this occurs, adĆ

just blower to longer time setting.

Figure 15 shows the various fan off" timings and how jumper

should be positioned. Unit is shipped with a factory fan off"

setting of 90 seconds. Fan off" time will affect comfort and

efficiency and is adjustable to satisfy individual applications.

The fan off" timing is initiated after a heating demand but not

after a blower or cooling demand (that is, when indoor therĆ

mostat switch is changed from ON to AUTO and heating/

cooling demand is not present, the blower stops immediateĆ

ly).

FIGURE 15

FANĆOFF TIME ADJUSTMENT

270

210

150

90

To adjust fanĆoff timing:

Remove jumper from BCC2Ć3 and seĆ

lect one of the other pin combinations

to achieve the desired time.

TIMING

JUMPER

TIMING

PINS

(seconds)

Leave jumper off for

330 second fanĆoff timing.

Loading...

Loading...