Page 28

12- If the furnace will not operate, follow the instructions

To Turn Off Gas To Unit" and call your service techniĆ

cian or gas supplier.

To Turn Off Gas To Unit

1 - Set thermostat to lowest setting.

2 - Turn off all electrical power to unit if service is to be

performed.

3 - Remove heat section access panel.

4 - On Honeywell VR8204 gas valves, turn knob on gas

valve clockwise to OFF. For White Rodgers 36E

gas valves, move switch to OFF. Do not force.

5 - Replace unit access panel.

C-Safety or Emergency Shutdown

Turn off unit power. Close manual and main gas valves.

D-Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED" mode. Close

all gas valves (both internal and external to unit) to guaranĆ

tee no gas leak into combustion chamber. Turn off power

to unit. All access panels, covers and vent caps must be in

place and secured.

Refer to Maintenance" section of this manual for instrucĆ

tions on how to prepare condensate assembly for exĆ

tended period shutdown.

IV-HEATING SYSTEM SERVICE CHECKS

A-A.G.A./C.G.A. Certification

All units are A.G.A. and C.G.A. design certified without

modifications. Refer to the G26 Operation and Installation

Instruction Manual Information.

B-Exhaust CO

2

and CO content

Carbon Dioxide is a colorless and odorless gas produced

in small amounts by all furnaces, including the G26, during

combustion process. When the unit is properly installed

and operating normally, the CO

2

content of the exhaust is

between 6.0% and 8.0% for natural gas and between

7.5% and 9.5% for L.P. gases. CO content will be less than

0.04% regardless of the gas used. If unit appears to be opĆ

erating normally at or beyond the upper limit of the CO

2

range, the unit should be checked for abnormally high CO.

Testing for abnormally high CO

2

and CO.

One method for testing the CO

2

/CO content is the BacharĆ

ach CO

2

test with the Fyrite CO

2

indicator. Other methods

of testing CO

2

/CO are available. Closely follow the instrucĆ

tions included in the test kit you choose. Follow the proceĆ

dure below in order to check CO

2

/CO on the G26 furnace.

1 - Drill size "R" or 11/32 in. on the exhaust vent, just exitĆ

ing the cabinet and tap 1/8-27 NPT. This hole will be

used to draw your CO

2

/CO sample.

2 - Install a hose barb connector into test hole.

3 - Attach end of Fyrite sampling tube to hose barb.

4 - Set thermostat to highest setting and allow unit to run

15 minutes.

5 - When CO

2

/CO testing is complete, turn off unit, reĆ

move hose barb from exhaust vent and use a1/8"

plastic plug to close off port.

C-Gas Piping

Gas supply piping should not allow more than 0.5"W.C.

drop in pressure between gas meter and unit. Supply gas

pipe must not be smaller than unit gas connection. See gas

pipe capacity table on page 6 of this manual.

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gas.

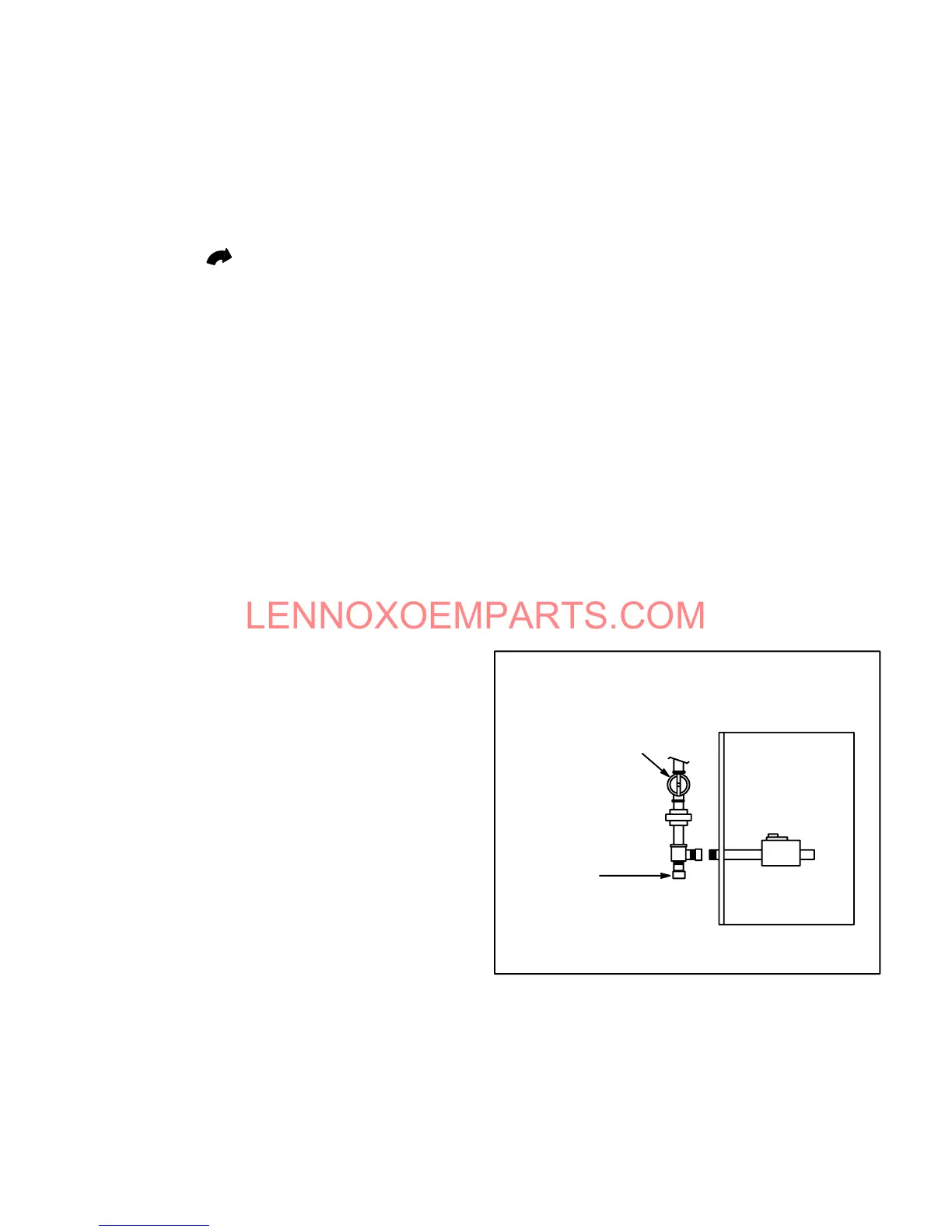

D-Testing Gas Piping

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged if

subjected to more than 0.5psig (14" W.C.). See figure 44. If

the pressure is equal to or less than 0.5psig (14"W.C.), use

the manual shut-off valve before pressure testing to isoĆ

late furnace from gas supply.

FIGURE 44

GAS VALVE WILL NOT HOLD TEST PRESSURE IN

EXCESS OF 0.5 PSIG (14"W.C.)

MANUAL MAIN SHUT-OFF

VALVE WILL NOT HOLD

NORMAL TEST PRESSURE

CAP

FURNACE

ISOLATE

GAS VALVE

GAS PIPING TEST PROCEDURE (TYPICAL)

Loading...

Loading...