Page 26

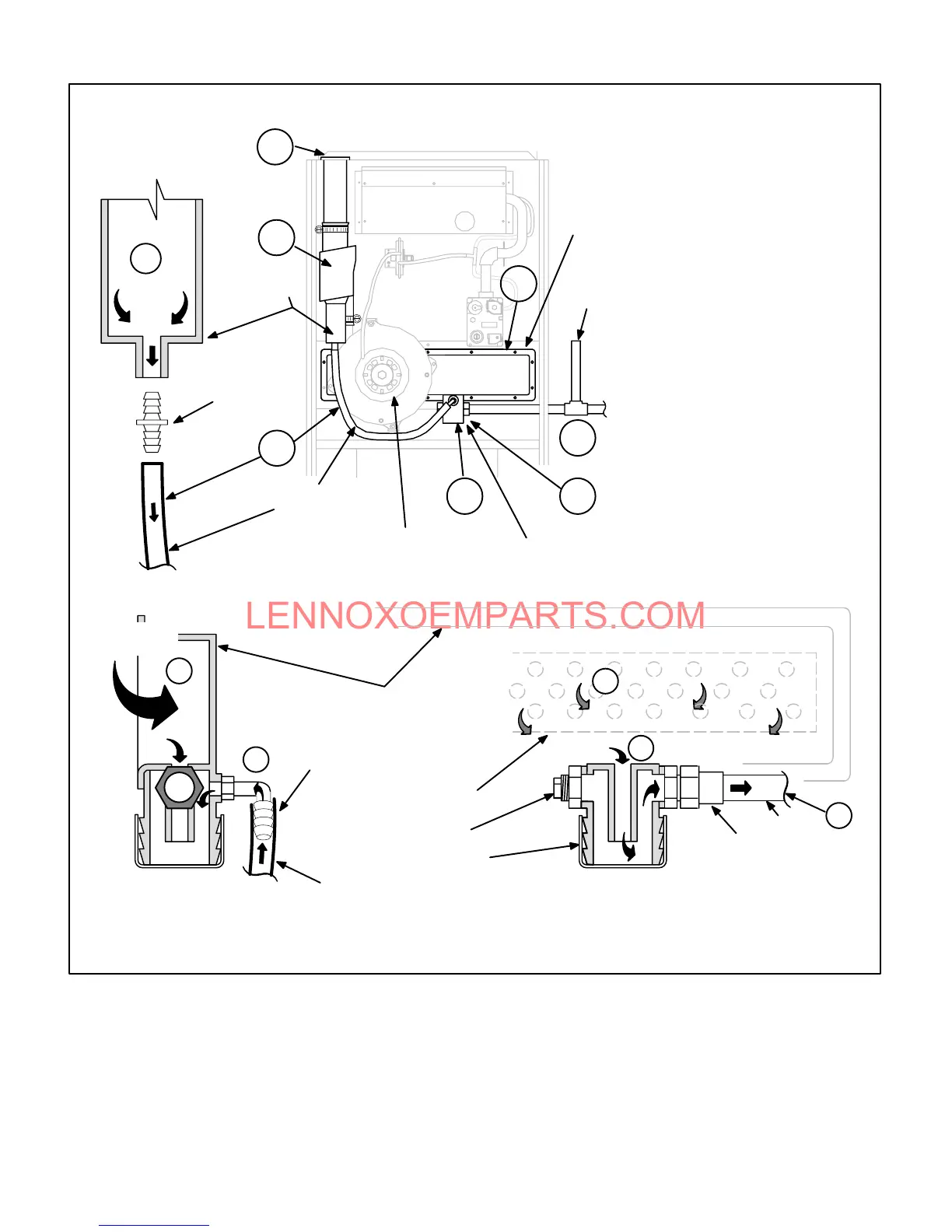

FIGURE 42

G26 -3 THROUGH -6 MODEL CONDENSATE

REMOVAL PROCESS

2

1

FLUE TRAP

COLD

HEADER

BOX

FLUE

DRAIN

HOSE

HEADER BOX

CONDENSATE TRAP

4

3

5

6

7

VENT

COMBUSTION

AIR BLOWER

Condensate Removal Process:

1- Condensate mixed with flue products

exits the coil and enters the cold headĆ

er box.

2- Condensate and flue products are sepaĆ

rated. Flue products are drawn into the

combustion air blower while condensate

is drained into the header box condenĆ

sate trap.

3- Flue products are expelled into the flue.

As flue products travel up and out, they

cool and more condensate is produced.

4- Condensate travels down the walls of

the flue pipe and into drain hose.

5- Water drains down through the flue

drain hose and is emptied into the

header box condensate trap.

6- When the cold header box condensate

trap is full, water begins draining out the

condensate drain pipe.

7- An external condensate trap is not reĆ

quired, but a vent is required. The vent

must extend above the height of the conĆ

denser coil (approx. 1 inch above the top

of the cold header box).

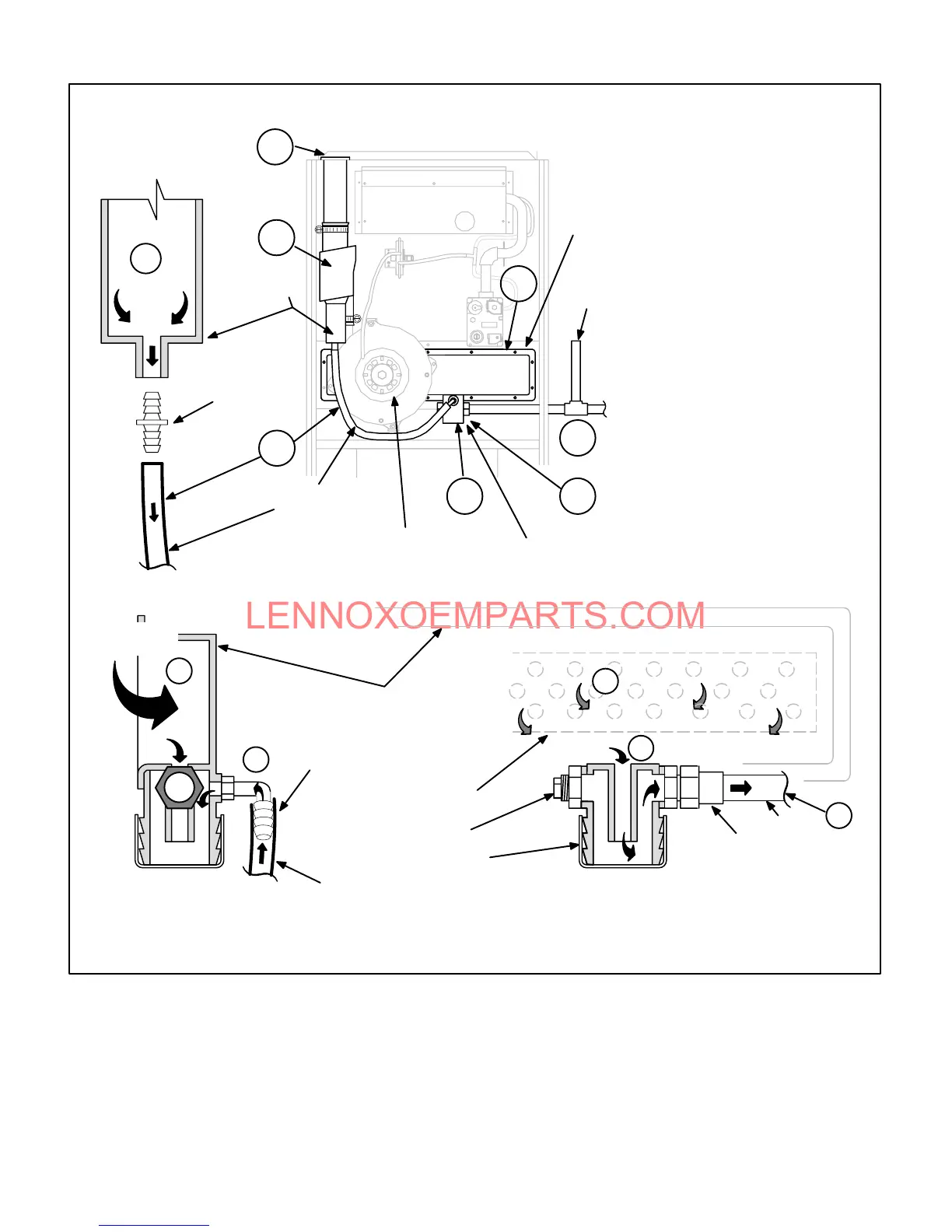

DETAIL OF COLD HEADER CONDENSATE TRAP

COLD HEADER BOX

HOSE BARB

RUBBER BOOT OR CAP

1/2"MPT PLUG

1/2"MPT TO FEMALE

PVC PIPE ADAPTER

1/2"PVC

1

COIL OPENING BEHIND

COLD HEADER BOX

2

DETAIL OF

FLUE TRAP

HOSE BARB

6

5

CONDENSATE

FROM COIL

1

4

FLUE DRAIN HOSE

SIDE DETAIL OF

HEADER BOX

CONDENSATION

TRAP

FRONT DETAIL OF

HEADER BOX

CONDENSATION

TRAP

6 - Connect condensate drain line (1/2" [13mm] SDR 11

plastic pipe or tubing) to condensate connection on

drip leg assembly and route to open drain. CondenĆ

sate line must be sloped downward away from drip

leg to drain. If drain level is above drip leg, condenĆ

sate pump must be used to condensate line. CondenĆ

sate drain line should be routed within the conditioned

space to avoid freezing of condensate and blockage

of drain line. If this is not possible, a heat cable kit may

be used on the condensate drip leg and line. Heating

cable kit is available from Lennox in various lengths;

6ft. (1.8m) - kit no. 18K48; 24ft. (7.3m) - kit no. 18K49;

and 50ft. (15.2m) - kit no. 18K50.

III-STARTĆUP

A-Preliminary and Seasonal Checks

1 - Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

Loading...

Loading...