Page 30

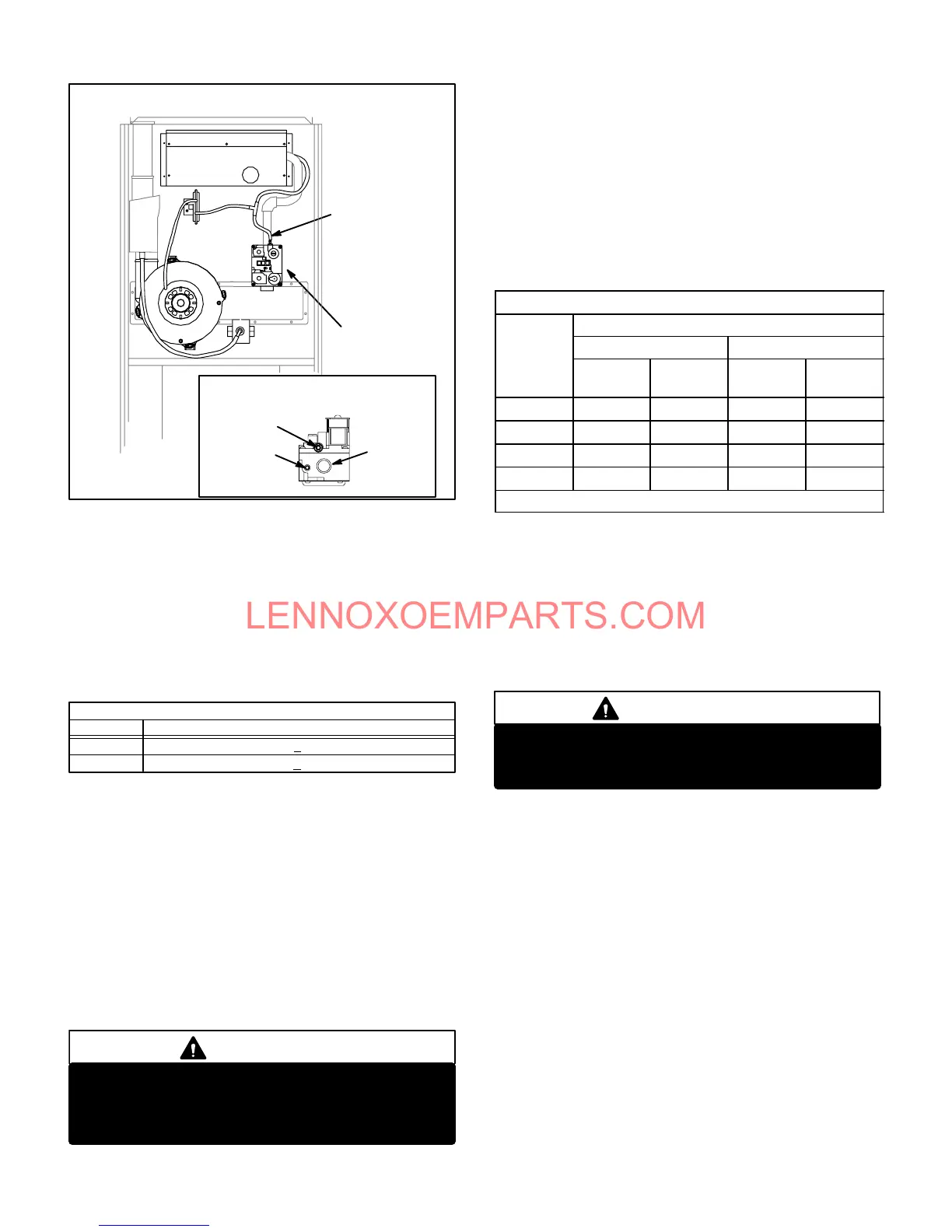

FIGURE 46

MANIFOLD CHECK

GAS

VALVE

SENSING

HOSE

GAS

VALVE

TOP VIEW GAS VALVE DETAIL

OUTLET

PRESSURE

TAP

HOSE

BARG

GAS

PIPING

4 - While waiting for the unit to stabilize, notice the flame.

Flame should be stable and should not lift from burner.

Natural gas should burn blue. L.P. gas should burn

mostly blue with some orange streaks.

5 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to values given in

table 9. Regulator cap must be installed when reading

pressures.

Absolute Pressure (outlet) in. W.C.

TABLE 9

GAS VALVE REGULATION*

3.5 +0.3

Natural

L.P.

7.5 +0.7

Unit (Fuel)

NOTE-Shut unit off and remove manometer as soon as

an accurate reading has been obtained. Take care to

replace pressure tap plug.

NOTE-During this test procedure, the unit will be

overfiring:

Operate unit only long enough to obtain accurate readĆ

ing to prevent overheating heat exchanger.

Attempts to clock gas valve during this procedure

will be inaccurate. Measure gas flow rate only during

normal unit operation.

6 - When test is complete remove obstruction from hose

and return hose to gas valve barb.

WARNING

Fire and explosion hazard.

These instructions MUST be followed exactly.

Can cause a fire or explosion resulting in property

damage, personal injury or loss of life.

G- Proper Gas Flow (Approximate)

Furnace should operate at least 5 minutes before checkĆ

ing gas flow. Determine time in seconds for two revoluĆ

tions of gas through the meter. (Two revolutions assures

a more accurate time.) Divide by two and compare to time

in table 10 below. Adjust manifold pressure on gas valve

to match time needed.

NOTE- To obtain accurate reading, shut off all other

gas appliances connected to meter.

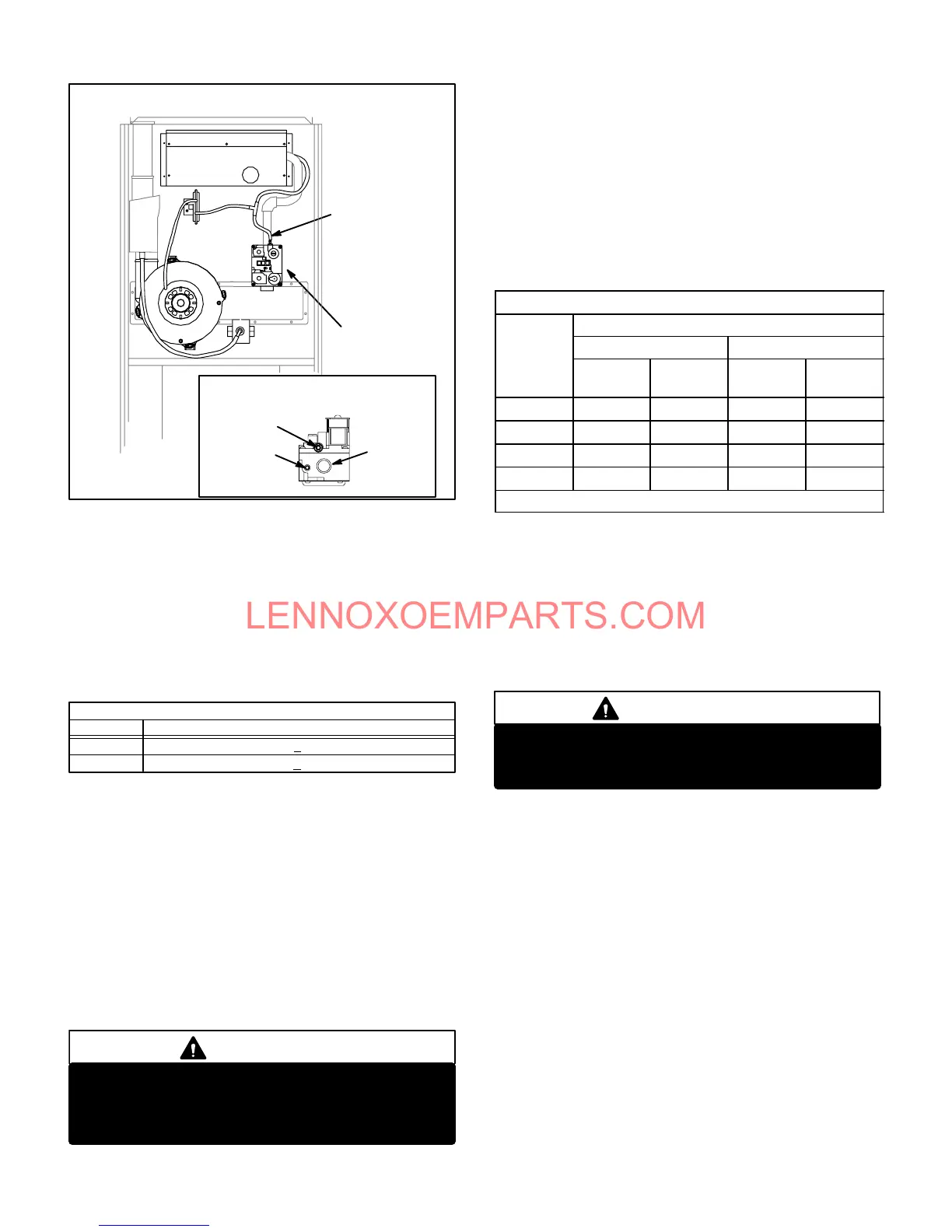

TABLE 10

GAS METER CLOCKING CHART

Seconds for One Revolution

Natural LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

-50 72 144 180 360

-75 48 96 120 240

-100 36 72 90 180

-125 29 58 72 144

Natural-1000 btu/cu ft LP-2500 btu/cu ft

H-High Altitude Derate

Units are selfĆcompensating for altitude and do not require

kits or adjustment when installed below 7500 ft. elevation.

Manifold pressure should remain the same for both natural

and propane. If unit is installed at an altitude higher than

7500 feet (2248 m), refer to local codes.

NOTE-This is the only permissible field derate for this

appliance.

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

I-Flame Signal

A 20 microamp DC meter is needed to check the flame sigĆ

nal on the SureLight and Johnson G776 ignition control. Use

a flame signal transducer (part number 78H5401) available

from Lennox to measure the flame signal.

Flame (microamp) signal is an electrical current which

passes from the ignition control through the sensor elecĆ

trode during unit operation. Current passes from the senĆ

sor through the flame to ground to complete a safety cirĆ

cuit.

To Measure Flame Signal:

1 - Set the volt meter to the DC voltage scale. Insert transĆ

ducer into the VDC and common inputs. Observe corĆ

rect polarities. Failure to do so results in negative (-)

values.

2 - Turn off supply voltage to control.

3 - Disconnect flame sensor lead from terminal of ignition

control.

Loading...

Loading...