Maintenance/repair

Maintenance operations

Checking the component parts

8

43

Lenze ¯ BA 33.0005 ¯ 5.0

8.3.3 Checking the component parts

With a mounted brake ¯ Check ventilation function and activation/deactivation

¯ Check air gap (if required, re−adjust it)

¯ Measure rotor thickness (if required, replace rotor)

¯ Thermal damage of the armature plate or flange

(tarnished in dark blue)

44

44

43

With a dismounted brake ¯ Check clearance of the rotor gear teeth (replace rotors that

are damaged by vibration)

¯ Damage by vibration of the torque support at the sleeve

bolts, cylindrical pins, and armature plate

¯ Check springs for damage

¯ Check armature plate and flange or end shield

– Evenness for size 06...12 < 0.06 mm

– Evenness from size 14 < 0.1 mm

– Max. run−in depth = rated air gap of the design size

45

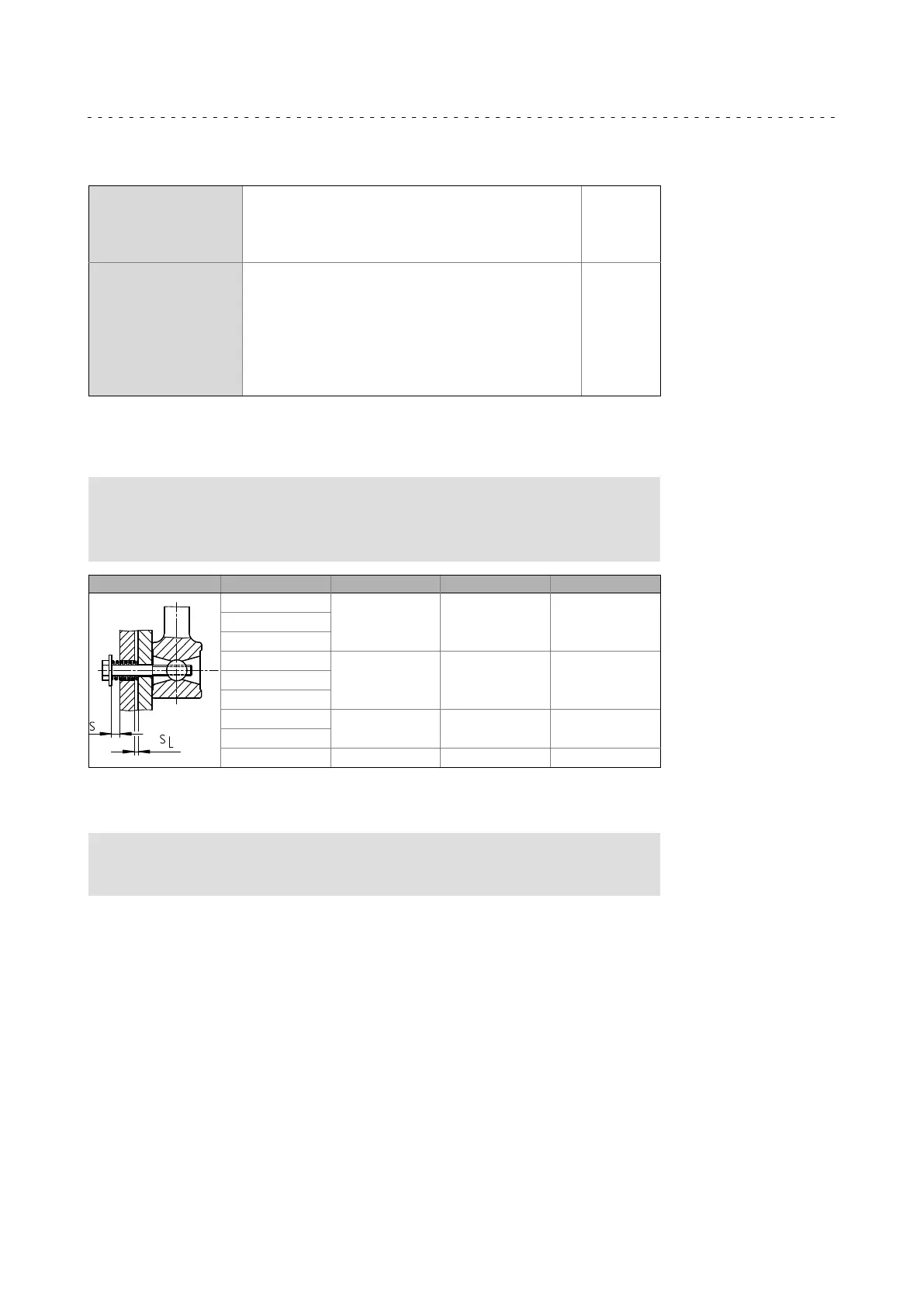

Check the mounting dimension of the manual release

Stop!

Dimension "s" must be maintained! Check air gap "s

L

"!

( operating instructions)

Size s

L

(mm) s

+0.1

(mm) s + s

L

(mm)

06

0.2 1 1.208

10

12

0.3 1.5 1.814

16

18

0.4 2 2.4

20

25 0.5 2.5 3

8.3.4 Checking the rotor thickness

Danger!

When the rotor thickness is checked, the motor must not run.

1. Remove fan cover and cover ring if attached.

2. Measure rotor thickness with calliper gauge. If a friction plate is attached, ensure

a flanged edge at the outer diameter of the friction plate.

3. Compare measured rotor thickness with minimally permissible rotor thickness

(values 45).

4. If required, exchange the entire rotor. Description 45.

Loading...

Loading...