National Crane Published 4-23-2018 Control # 239-11 3-7

NBT40 SERIES OPERATOR MANUAL OPERATING CONTROLS & PROCEDURES

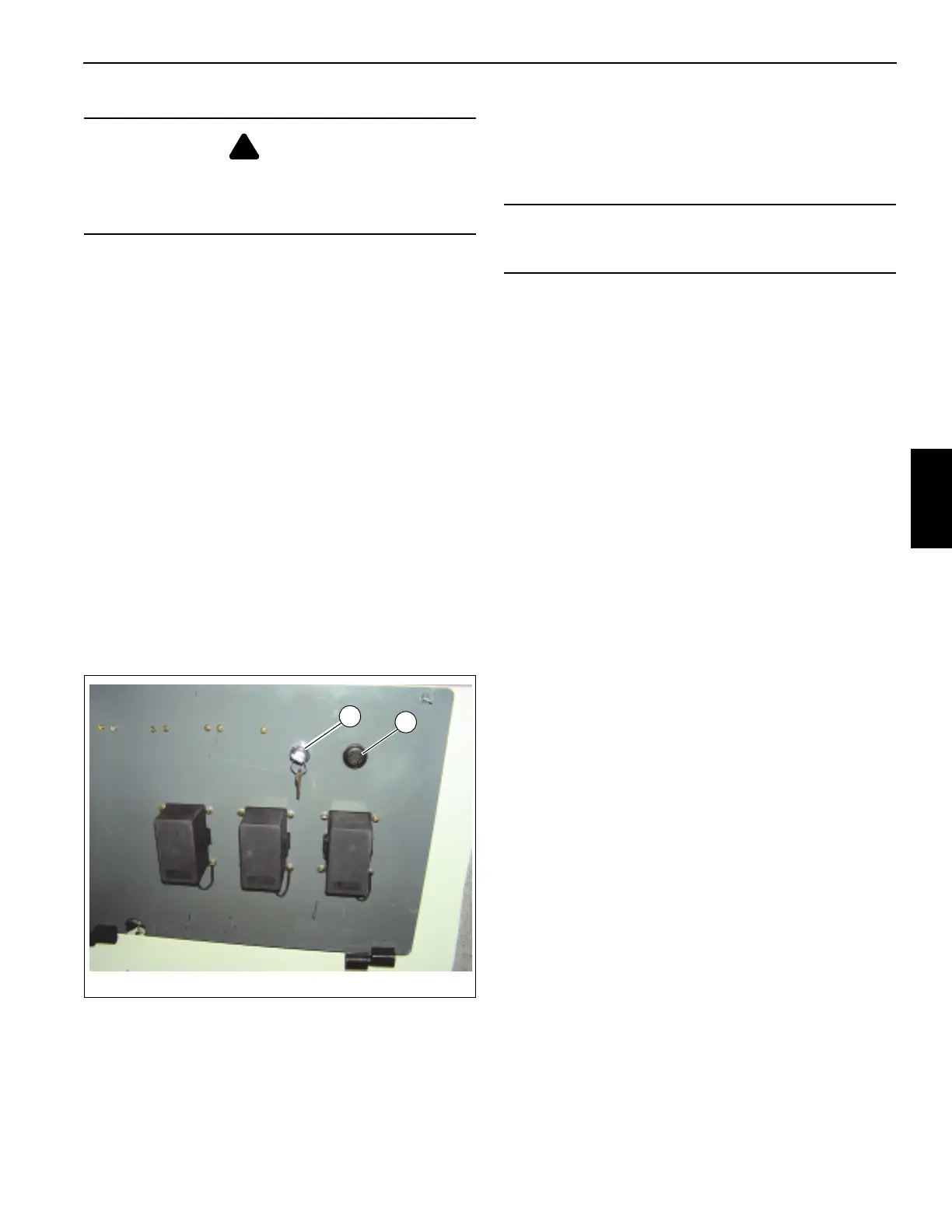

RCL and Minimum Wrap Bypass Switch

The RCL Bypass Switch (6, Figure 3-3) is a momentary on-

off switch, turn the key to the On position (right) to

disengaged the RCL controls and minimum wrap lockout

controls. Releasing the key allows the RCL and minimum

wrap controls to re-engage.

The RCL and 3 wrap system will be bypassed only as long

as the switch (6, Figure 3-3) is in the On position.

Turning the key switch (6, Figure 3-3) to the On position re-

engages the boom down, telescope out and hoist controls.

These functions were disabled when an overload condition

was sensed by the Rated Capacity Limiter (RCL). It is

important to read and understand the RCL Override Warning

information in the RCL Operator’s Manual before using the

RCL Bypass switch (6) or the RCL on/off switch.

The bypass switch (6, Figure 3-3) will also re-engage the

main and auxiliary hoist controls disabled by the minimum

wrap indicator sensor system.

The RCL control can be turned completely off and back on

using the switch (1, Figure 3-5) located behind the cab seat.

Hydraulic Oil Indicator

The hydraulic oil temperature warning light (7, Figure 3-3) is

located on the crane cable console and illuminates when the

hydraulic oil overheats. If overheating occurs, run the crane

at idle with the controls in neutral until the light goes out.

Swing Brake Indicator

The swing brake indicator (8, Figure 3-3) is located on the

crane cab console. The indicator light is on when the swing

brake is activated.

Main Hoist Minimum Wrap Indicator

When the main hoist is down to the last cable wrap the

minimum wrap indicator (9, Figure 3-3) will flash intermittent

and the minimum wrap buzzer (2, Figure 3-5) will sound

intermittently.

When the amount of cable left on the hoist reaches the

minimum wrap; the indicator light will be constant, the buzzer

will be constant and the hoist will be disabled by the

minimum wrap sensor system.

Main Hoist Speed Switch

The main hoist speed selector switch (10, Figure 3-3) is

located on the right seat armrest. It is a three position switch

(on-off-on), placarded as rabbit (fast) hoist motor speed and

turtle (slow) hoist motor speed.

Hand Throttle Control

The push/pull hand throttle (11, Figure 3-4) is located on the

crane cab console and has the following functions.

Increase Engine Speed - Push in and hold the center button

(1, Figure 3-6); pull out on the knob (2) to accelerate the

engine. Releasing button (1) will lock knob in place and

maintain engine speed.

Decrease Engine Speed - Push in and hold the center button

(1, Figure 3-6); push the knob (2) in to slow the engine

speed.

Incremental Speed Adjustment - Rotate knob (2, Figure 3-6)

clockwise to increase speed and counterclockwise to

decrease engine speed.

The hand throttle must be positioned as shown in Figure 3-6

to operate the foot throttle (4, Figure 3-4) properly.

DANGER

The RCL only aids the operator when properly

programmed with the proper load chart and crane

configuration. To prevent injury or death to personnel, be

sure the RCL is programmed before crane operation.

NOTICE

Do not operate the crane with overheated hydraulic oil or

damage to seals in the hydraulic components may result.

Loading...

Loading...