National Crane Published 4-23-2018 Control # 239-11 4-7

NBT40 SERIES OPERATOR MANUAL SET-UP

INSTALLING CABLE ON THE HOIST

NOTE: The cable should preferably be straightened before

installation on the hoist drum.

Install cable on the hoist drum in accordance with the

following procedure.

3. Position the cable over the boom nose sheave and route

to the hoist drum.

4. Position the hoist drum with the cable anchor slot on top.

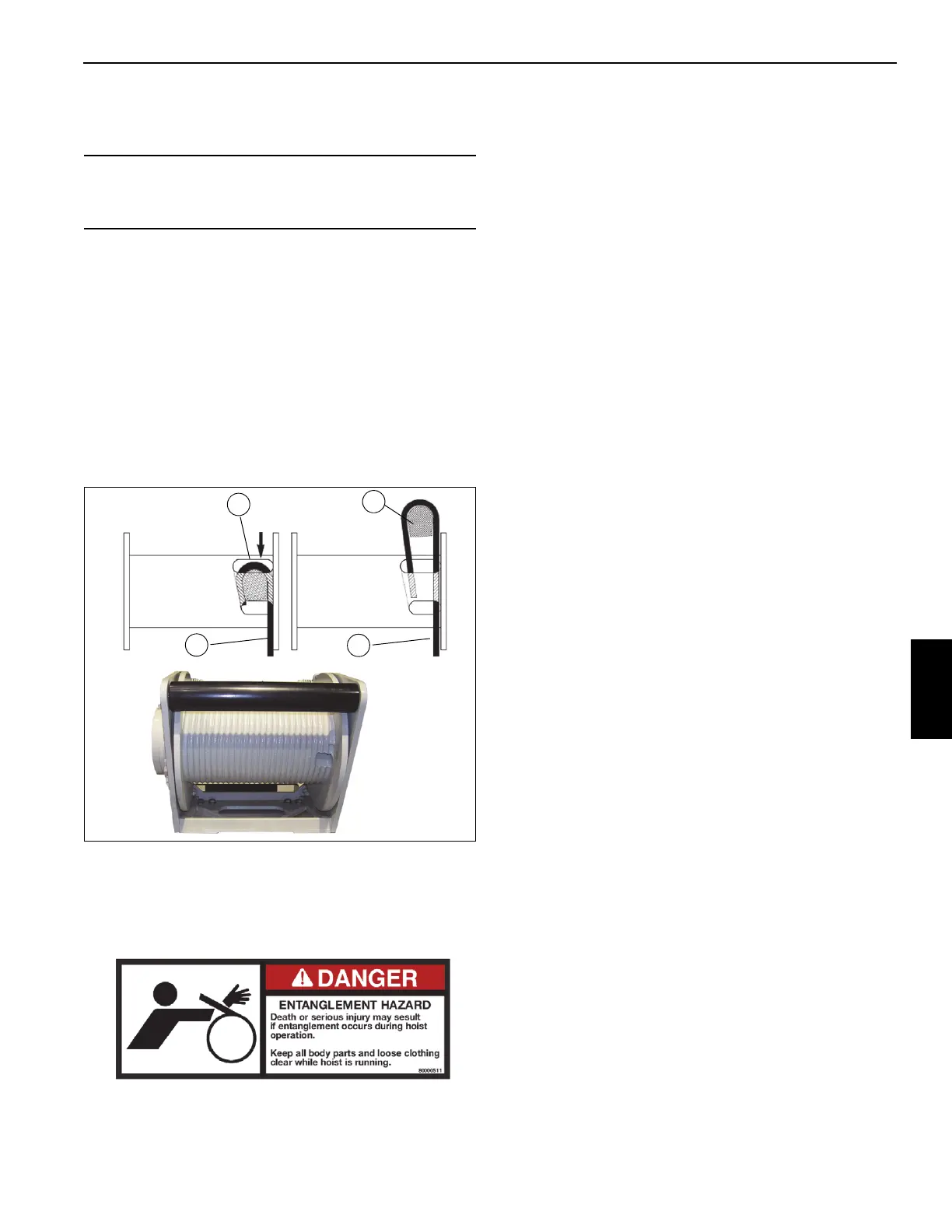

5. Insert the cable through the slot and position around the

anchor wedge (1) Figure 4-4.

NOTE: The end of the cable should be even with the

bottom of the slot for the anchor wedge.

6. Position the anchor wedge in the drum slot; pull firmly on

the free end (2) of the cable to secure the wedge.

NOTE: If the wedge does not seat securely in the slot,

carefully tap (3) the top of the wedge with a mallet.

7. Slowly rotate the drum, ensuring the first layer of cable is

evenly wound onto the drum.

8. Install the remainder of the cable, as applicable.

9. Attach the wedge socket to the free end of the cable as

shown in (Figure 4-6). If you are using a terminator

wedge socket, see Figure 4-5.

10. Torque the clamp on the dead end of the cable to 95 ft-lb

(128 Nm).

NOTE: The torque must be rechecked after the initial

operation of the crane. Be sure cable the clamp is

attached to the dead end of the cable only.

11. Start winding the cable onto the hoist drum. Maintain

about 500 pounds (250 kg) of tension on the cable.

12. Keep the cable wraps tight against each other when the

first half of the bare hoist is filling. The second half of the

hoist should wrap tightly because the fleet angle of the

cable tends to pull the cable to the center of the drum

thus wrapping tightly.

13. Continue winding the cable on the second, third and

fourth layer of the hoist. Keep the cable paying in

straight to the boom to avoid side loading the boom. The

preceding layers will wrap smoothly guided by the first

layer wrapping.

WEDGE SOCKETS

To install a wedge socket:

• Make sure the wedge socket is the proper size for the

cable.

• Do not mix components of different wedge socket

manufacturers.

• The wedge socket must meet the requirements of the

wedge socket and wire rope manufacturers.

State and local laws may vary and require different

attachment methods depending upon work conditions. The

user is responsible for alternate attachment methods.

Terminator Wedge Installation

The NBT40 SERIES is shipped with a terminator wedge

socket which is National Crane’s preferred type of socket

(Figure 4-5). Other wedge socket types are shown on

page 4-8.

To attach a terminator wedge Figure 4-5, use the following

procedure:

1. Match the socket, wedge, and clip to the wire rope and

size the rope with the go and no go hole in the socket.

• The wire rope must pass through the “go” hole and

not pass through the “no go” hole.

CAUTION

If cable is wound from the storage drum, the reel should

be rotated in the same direction as the hoist.

Loading...

Loading...