22

Pellerin Milnor Corporation

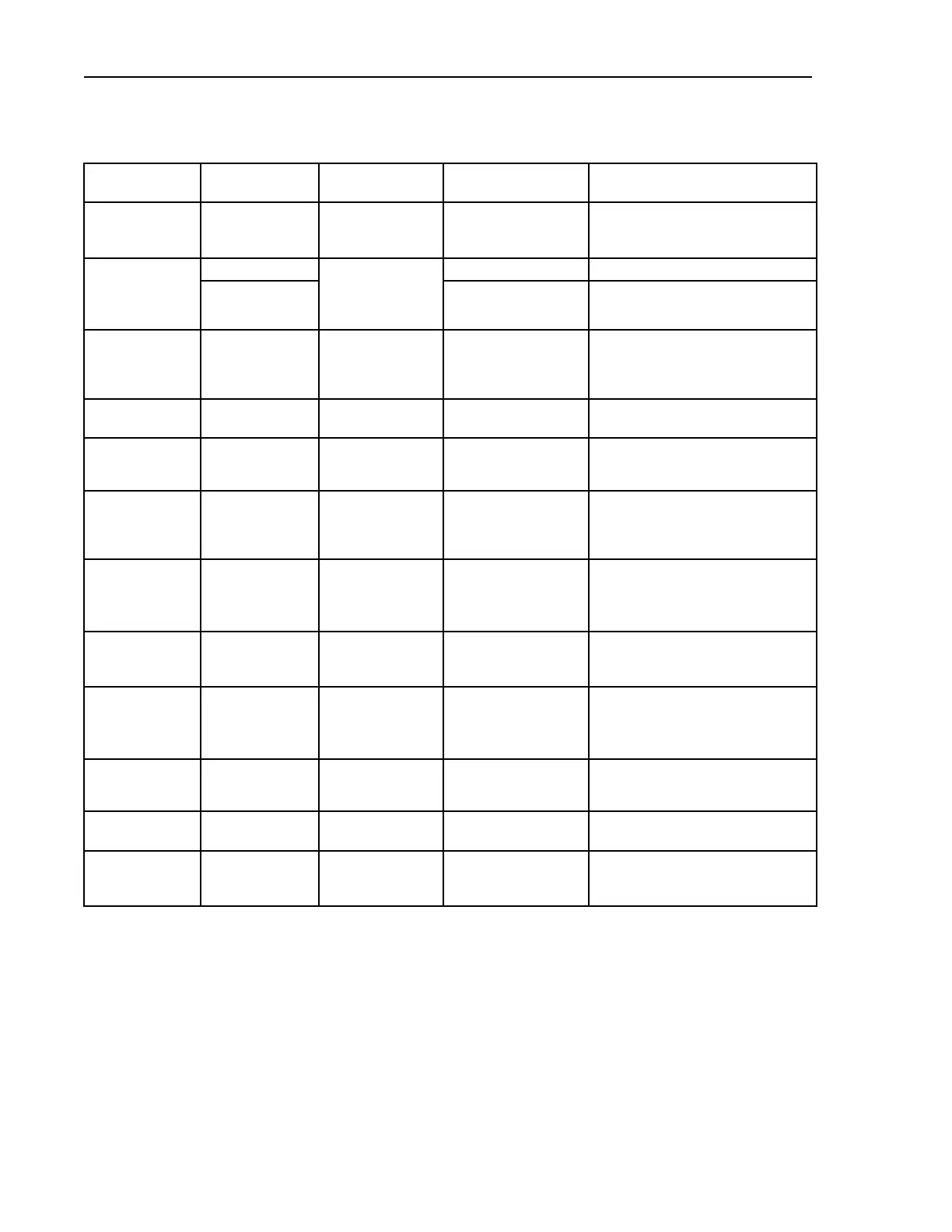

Table 8 Contamination Types, Cleaning Agents, and Procedures (cont'd.)

Material or

Component

Usual

Contamination

Example

Cleaning Agent

More Data

electrical

connections

corrosion, varnish spade connector,

molex connector,

plug-in relay

spray solvent for elec-

trical components

Disconnect then connect it again.

Use solvent if the bad connection

continues.

electronic sensors dust photoeye lens, re-

flector, laser, prox-

imity switch,

temperature probe

none

Use a clean, soft, dry cloth.

dirt warm water with soap,

then water flush

Use clean, soft cloths.

stainless steel chemical spill shell, supply

injector

water

Use a hose to flush the chemical

supply from the surface fully. Do

not get water on electrical compo-

nents or mechanisms.

300 series stain-

less steel

chemical corro-

sive attack

shell interior,

cylinder

pickling and

passivation

Speak to your dealer or Milnor. This

is not routine maintenance.

painted metal,

unpainted

aluminum

dust, dirt, grease frame members warm water with soap,

then water to flush

Use clean cloths. Do not get water

in electrical components.

rubber dirt, oil, grease drive belts, hoses warm water with soap,

then water to flush

Use clean cloths. Flush fully. Oil or

soap must not stay on drive belts.

Make sure that drive belts are

serviceable.

clear plastic,

acrylic

discoloration

(yellowing)

compressed air fil-

ter bowl, visual

flow meter

warm water with soap,

then water to flush,

then acrylic cleaner.

Do not use ammonia.

Use only the necessary cleaning

agents. Wash and rinse with clean,

soft cloths. Follow instructions on

acrylic cleaner.

glass discoloration

(yellowing)

door glass, site

glass

ammonia and water

solution and water

rinse then acetone

Use clean, soft cloths. Use only the

necessary cleaning agents. If neces-

sary, soak in cleaner.

soft air filter, lint

filter,

dust, lint on inverter electric

box door, in air

line filter bowl, in

dryers

shop vacuum Replace the used with a new filter

when the vacuum cannot remove

contamination.

rigid strainers,

screens for water,

steam

mineral particles in water line, y-

strainer

water

Use a rigid bristle brush. Flush with

a flow of water.

rigid strainers,

screens for oil

metal shavings in hydraulic line carburetor cleaner or

equivalent solvent

Soak. Use a rigid bristle brush.

steel drive

components

dirt, hardened

lubricant

bearings, roller

chains, sprockets,

gears

carburetor cleaner or

equivalent solvent

Soak. Use a cloth or soft bristle

brush.

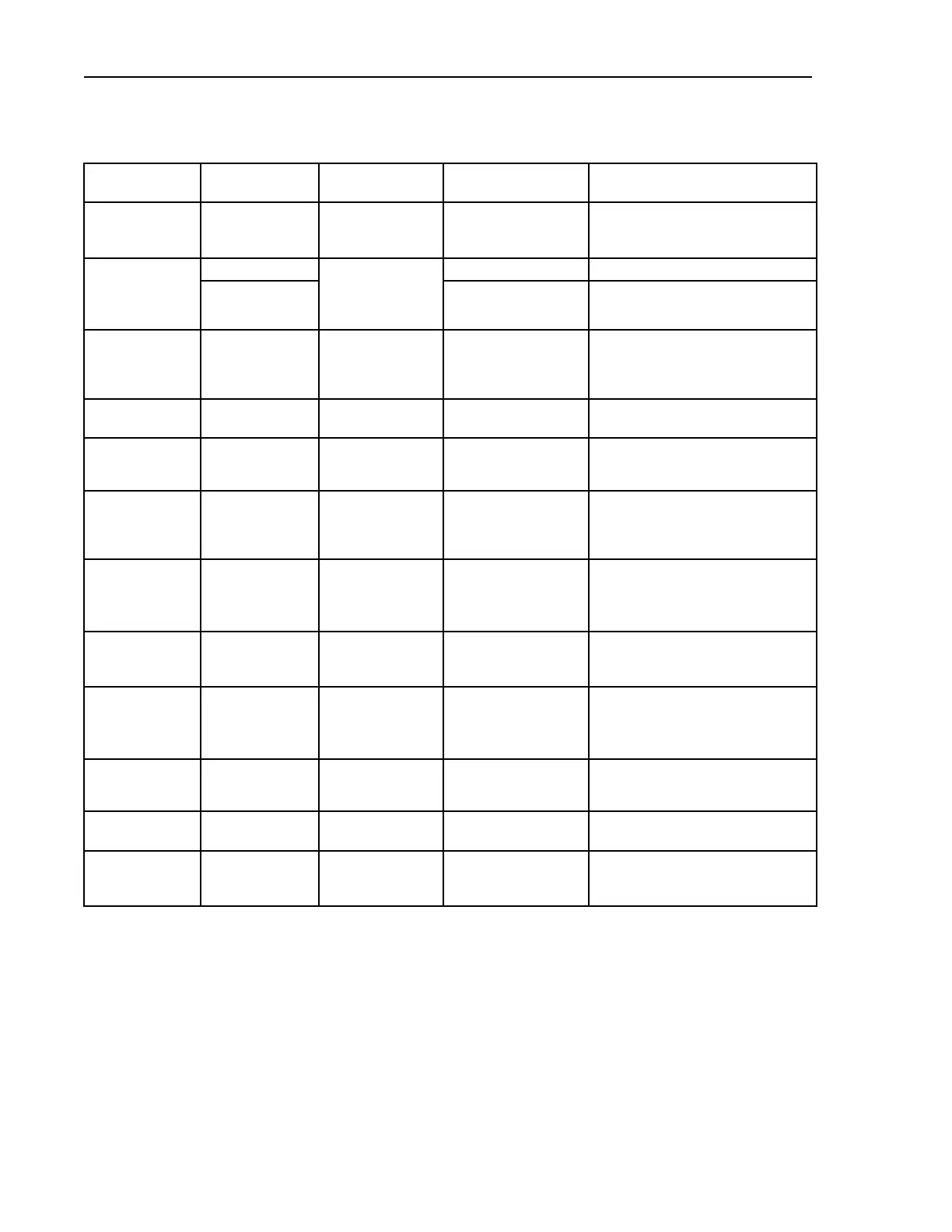

3.1.3 Lubricant Identification

BNUUUH01.R04 0000335793 A.5 A.26 A.13 11/8/21 11:43 AM Released

The table below identifies the lubricant for each lubricant code given in the maintenance sum-

mary. Get these or equivalent lubricants from your local lubricant supplier.

When you add grease, always use the procedures given in Section 3.1.4 : Grease Gun Procedures,

page 23. When you add grease to motors, also use the procedures given in Section 3.1.6 : Proce-

dures for Motors, page 24.

Routine Maintenance

Loading...

Loading...