Pellerin Milnor Corporation 25

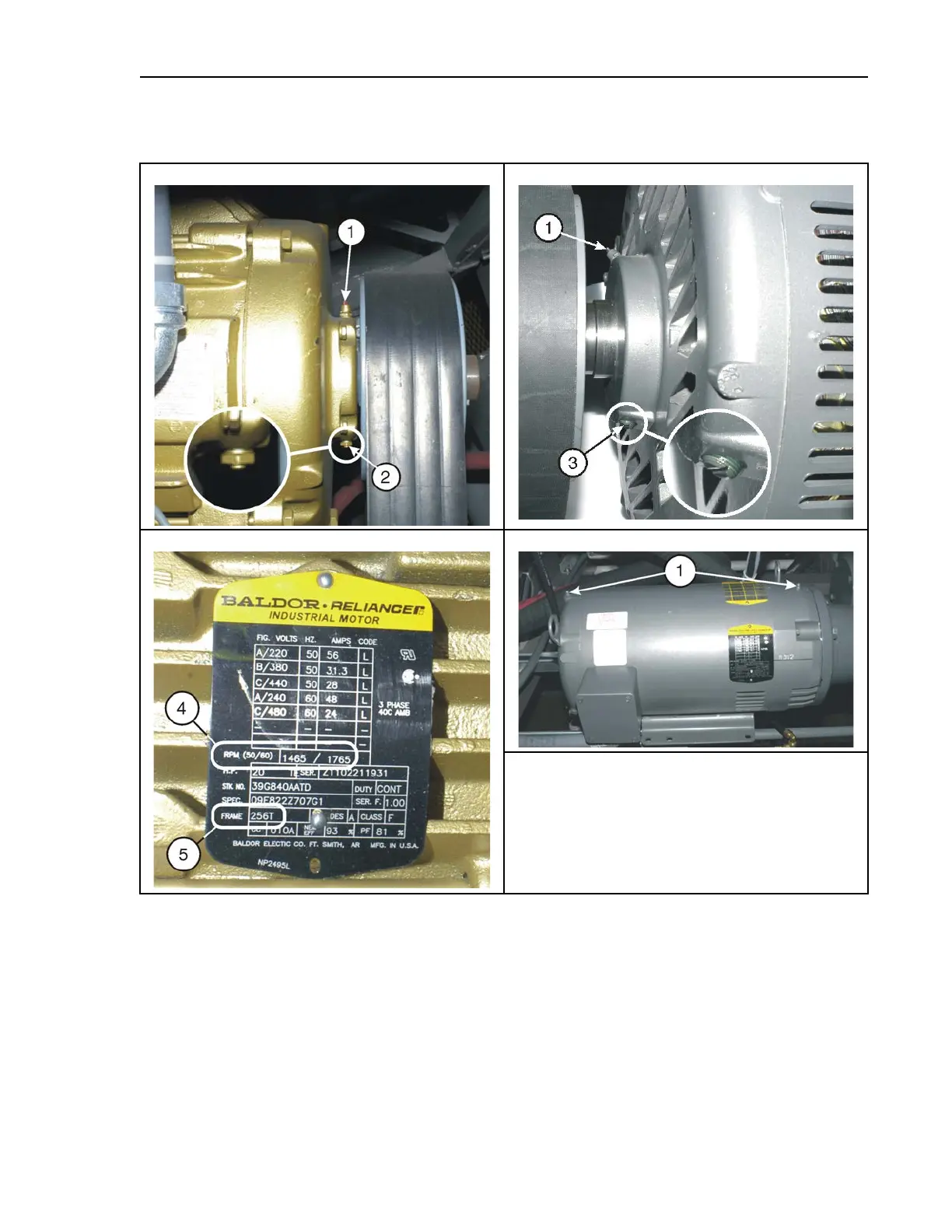

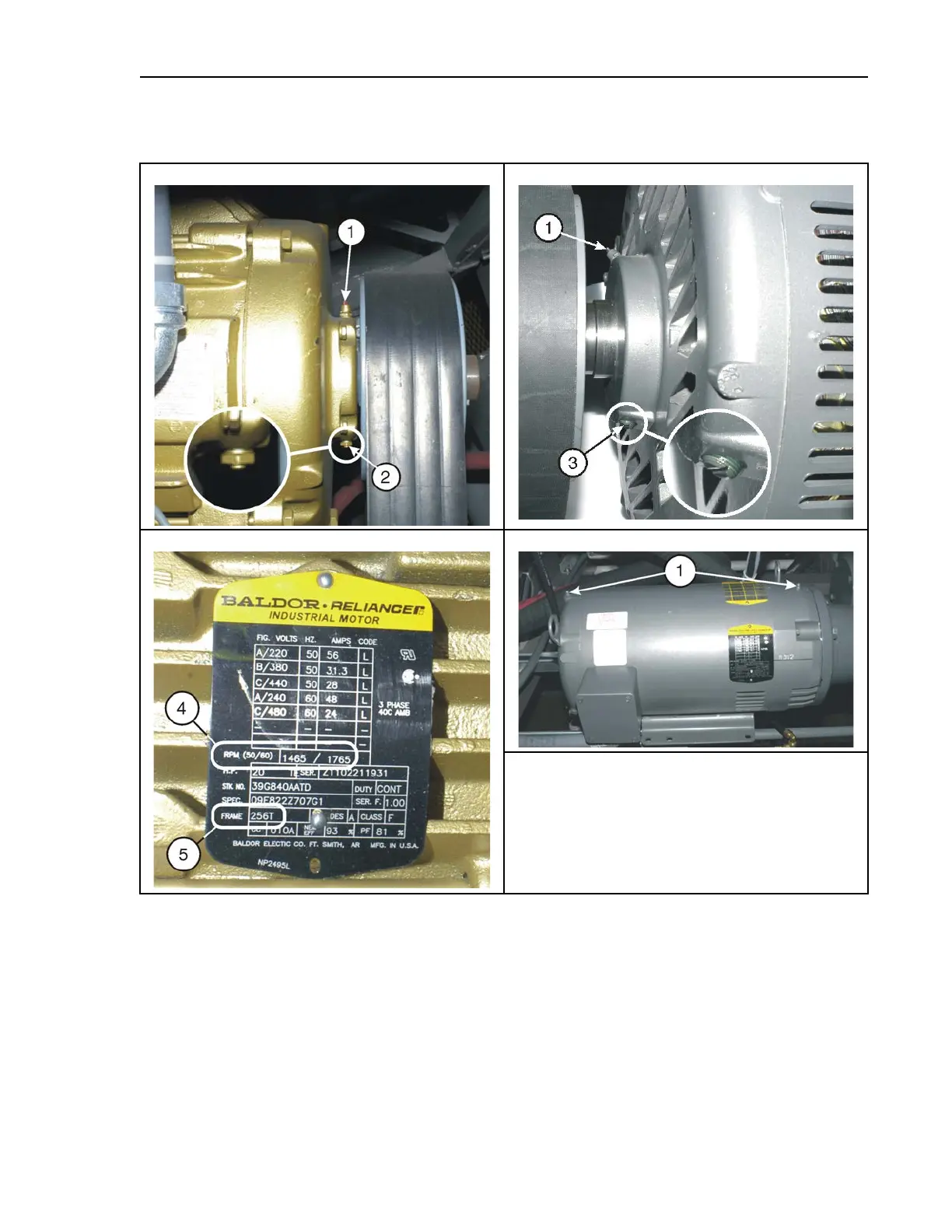

Figure 6. Motor Grease Maintenance Conditions

Grease Fitting and Grease Relief

Grease Fitting and Grease Drain

Motor Nameplate

Grease Fittings, No Reliefs or Drains

Legend

1...Grease fitting

2...Grease relief. Do not remove.

3...Grease drain plug. Remove first.

4...RPM (motor speed). This example is 1465 RPM

at 50 Hz and 1765 RPM at 60 Hz.

5...NEMA (IEC) frame size. Example: 256T

Apply grease as follows:

1. Operate the machine or use manual functions to operate the motor until it is warm.

2. Remove power from the machine.

3. If the motor has grease drain plugs, remove them. See the caution statement above..

4. Add grease EM (Table 9: Lubricant Identification, page 23 ) with the motor stopped. If the

motor with the nameplate in the above figure operates at 60 Hz, the specified grease quantity

for each grease fitting is 0.65 fl oz (18.4 mL).

Routine Maintenance

Loading...

Loading...