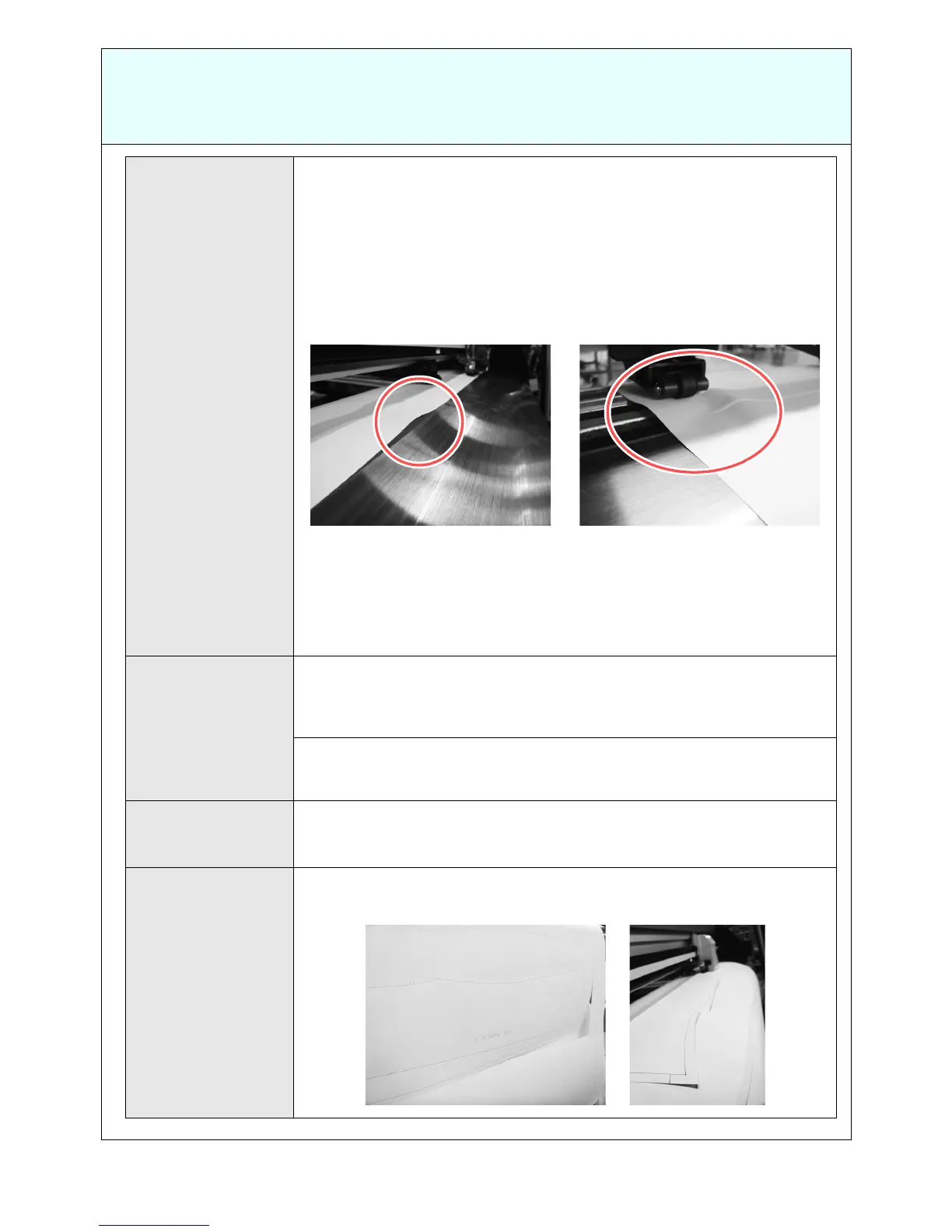

Check whether the

sheet is set prop-

erly.

(3) Check whether you perform pre-feed

Be sure to perform pre-feed. Roll sheet may expand or shrink not a little

due to the environment change by changing its status of being taken-up to

sagging. Because of this, the position relationship at the end of cutting

may be different from that at the start, or, the paper may skew and slant.

For the pre-feed setting method, refer to the Operation manual chapter

3 “Setting the PRE FEED”.

(4) Check whether the sheet does not float at the sheet detection.

If the sheet floats, reset it.

(5) Check whether the roll sheet that has not been wound tightly (sagging) is

not used.

If you rewind the roll sheet repeatedly, the sheet may sag due to expansion

and contraction of the media. If you set the sheet with surface waviness,

even tension cannot be applied on both right and left, and therefore, the

stable feeding cannot be performed.

Check whether a

usable sheet is

used.

Referring to the Operation manual chapter 5 “Specification-Settable

sheet”, check that it is a usable sheet with APC-130.

If you use a sheet other than the specified, the stable feeding may not be per-

formed.

A heavy sheet is used.

When you use a heavy sheet, set “Setting the SHEET TYPE” of the Setting

function to “HEAVY”. (For the setting method, refer to the Operation manual.)

Check whether con-

tinuous cutting has

not been performed.

If you perform continuous cutting, the sheet may be slanted gradually. In such

a case, after adjusting misalignment of the sheet using the hold function (refer

to the Operation manual), you can cut continuously.

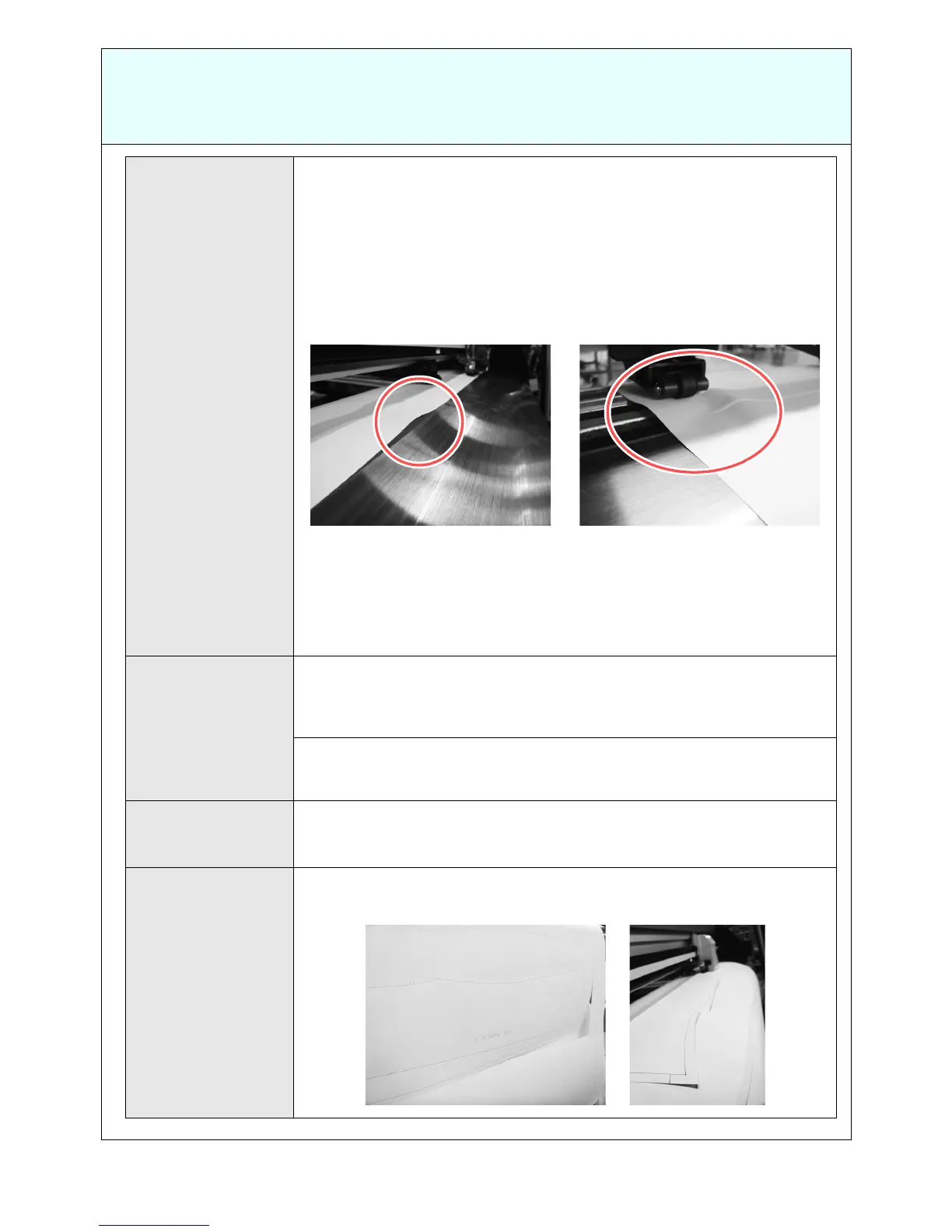

Check whether the

cut pattern does

not come off.

When the cut pattern comes off as described in the photo below, it may impact

on the feeding.

Loading...

Loading...