Filler

cap

Fill

with new

oil

from filler

port.

Make sure

that

the

filler

cap

is

tightened securely before starting

the

engine.

ENGINE

OIL

FILTER

REPLACEMENT

When necessary,

the

cartridge

type

engine oil filter shou

Id

be removed with

the

special

tool,

and replaced with a new

filter.

NOTE

1. Lightly apply

the

engine

oil

or grease

to

the

seal

surface

of

the

oil filter before mounting.

2. After

the

oil

filter has been screwed

in

and

the

rubber seal comes

in

contact

with

the

case surface,

screw

in

the

filter

2/3

turn

further

by hand.

3. After

mounting,

start

the

engine and inspect the

seal surface for leaks.

4. Replacing

the

filter causes

the

oil

to

be reduced by

the

volume

of

the

filter. Recheck the oil level after

running

the

engine for 5 minutes.

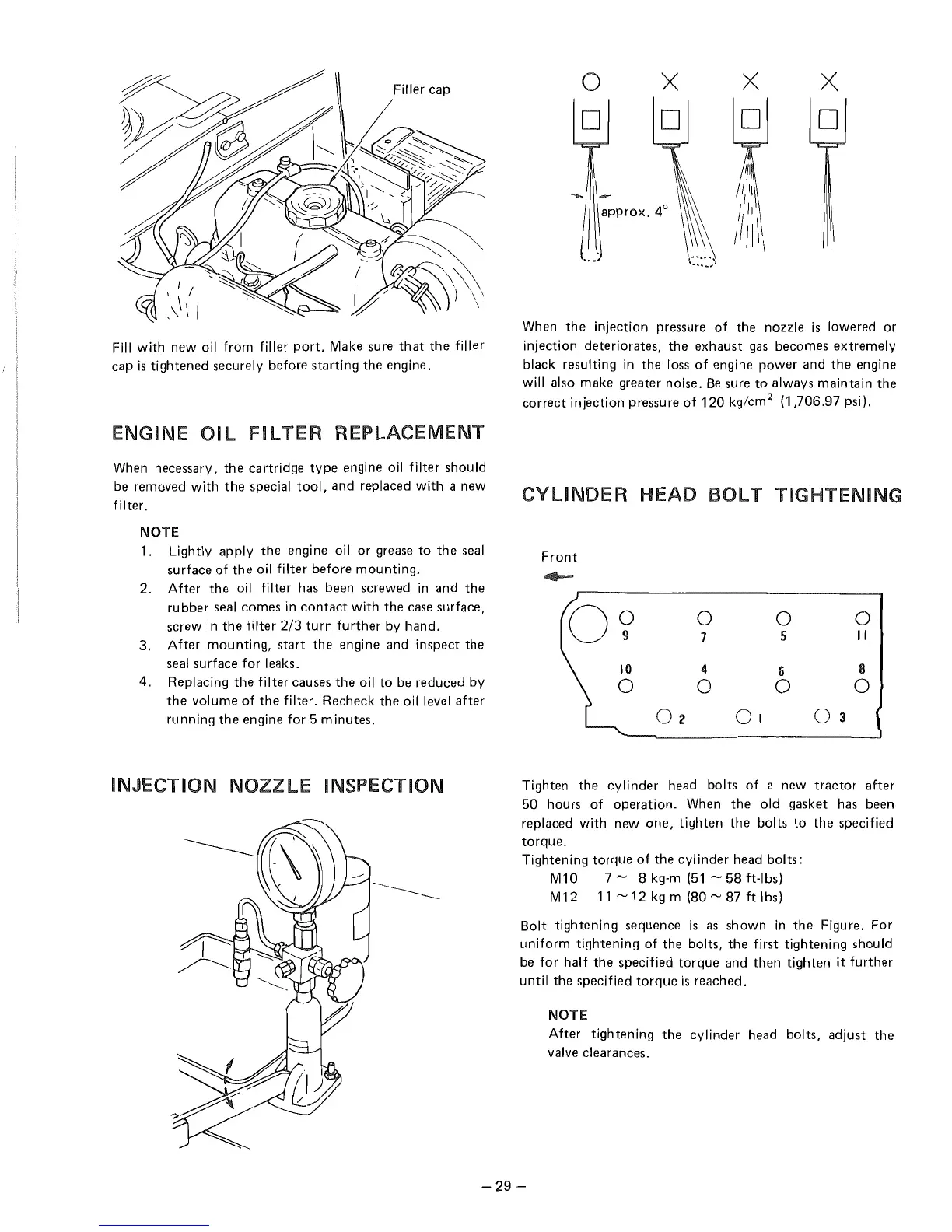

INJECTION

NOZZLE

INSPECTION

approx.4°

X

o

When

the

injection pressure

of

the

nozzle

is

lowered or

injection deteriorates,

the

exhaust

gas

becomes extremely

black resulting

in

the

loss

of

engine

power

and

the

engine

will also make greater noise.

Be

sure

to

always maintain the

correct

injection pressu

re

of

120

kg/cm

2

(1,706.97 psi).

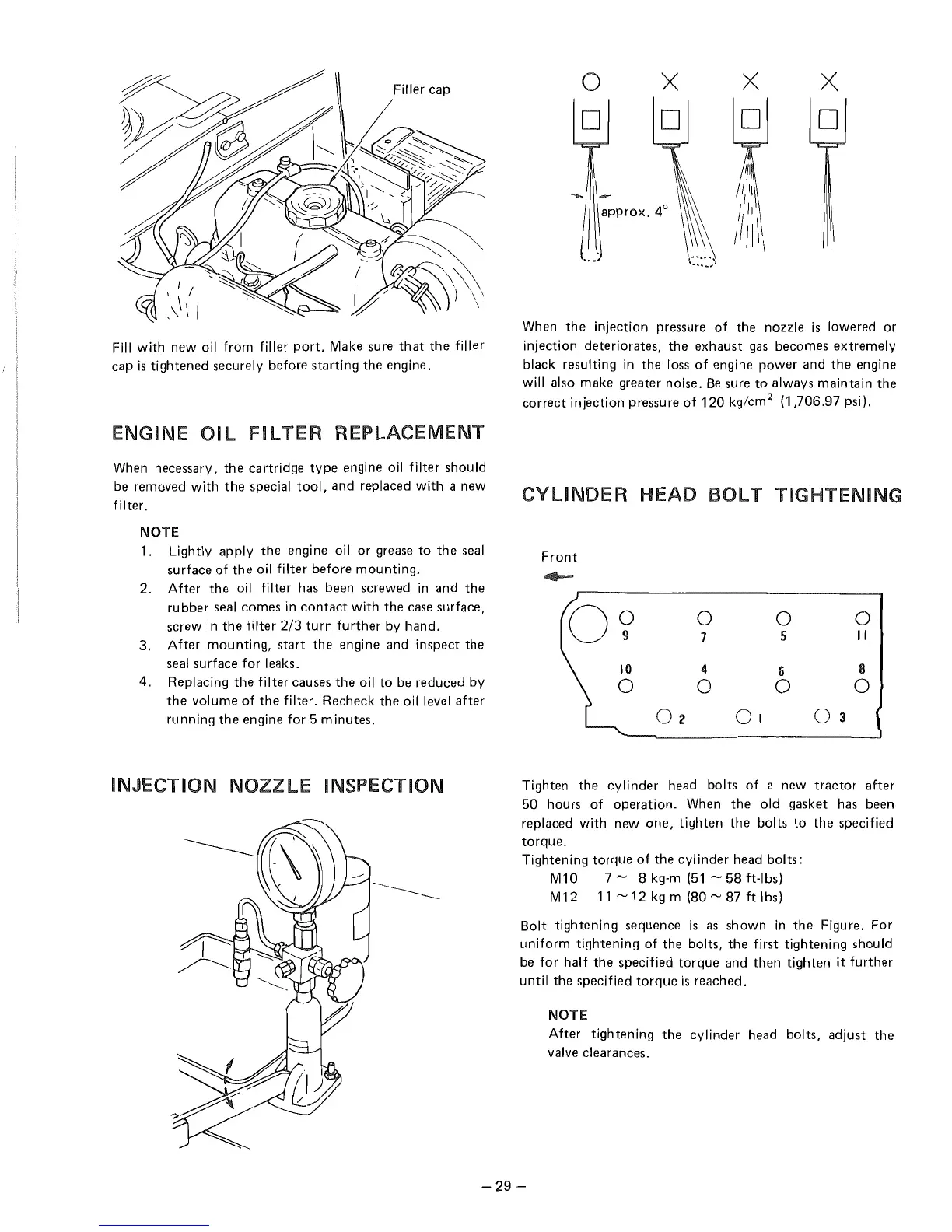

CYLINDER

HEAD

BOLT

TIGHTENING

Front

.......

02

o

7

4

o

o

5

6

o

03

o

II

8

o

Tighten the cylinder head bolts of a new

tractor

after

50

hours of operation. When

the

old gasket has been

replaced with new

one,

tighten

the

bolts

to

the

specified

torque.

Tightening

torque

of

the

cylinder head bolts:

M10

7~

8kg-m

(51

~58ft-lbs)

M12

11

~ 12 kg-m (80

~

87 ft-Ibs)

Bolt tightening sequence

is

as

shown

in

the

Figure. For

uniform tightening of

the

bolts,

the

first tightening should

be for half

the

specified

torque

and

then

tighten it

further

until the specified

torque

is

reached.

NOTE

After tightening

the

cylinder head bolts, adjust

the

valve clearances.

-29

-

Loading...

Loading...