14 APPENDIX

Mitsubishi Diesel Engine S16R & S16R2 OPERATION & MAINTENANCE MANUAL

206

Pub. No. K29001-00320 Revision: 1

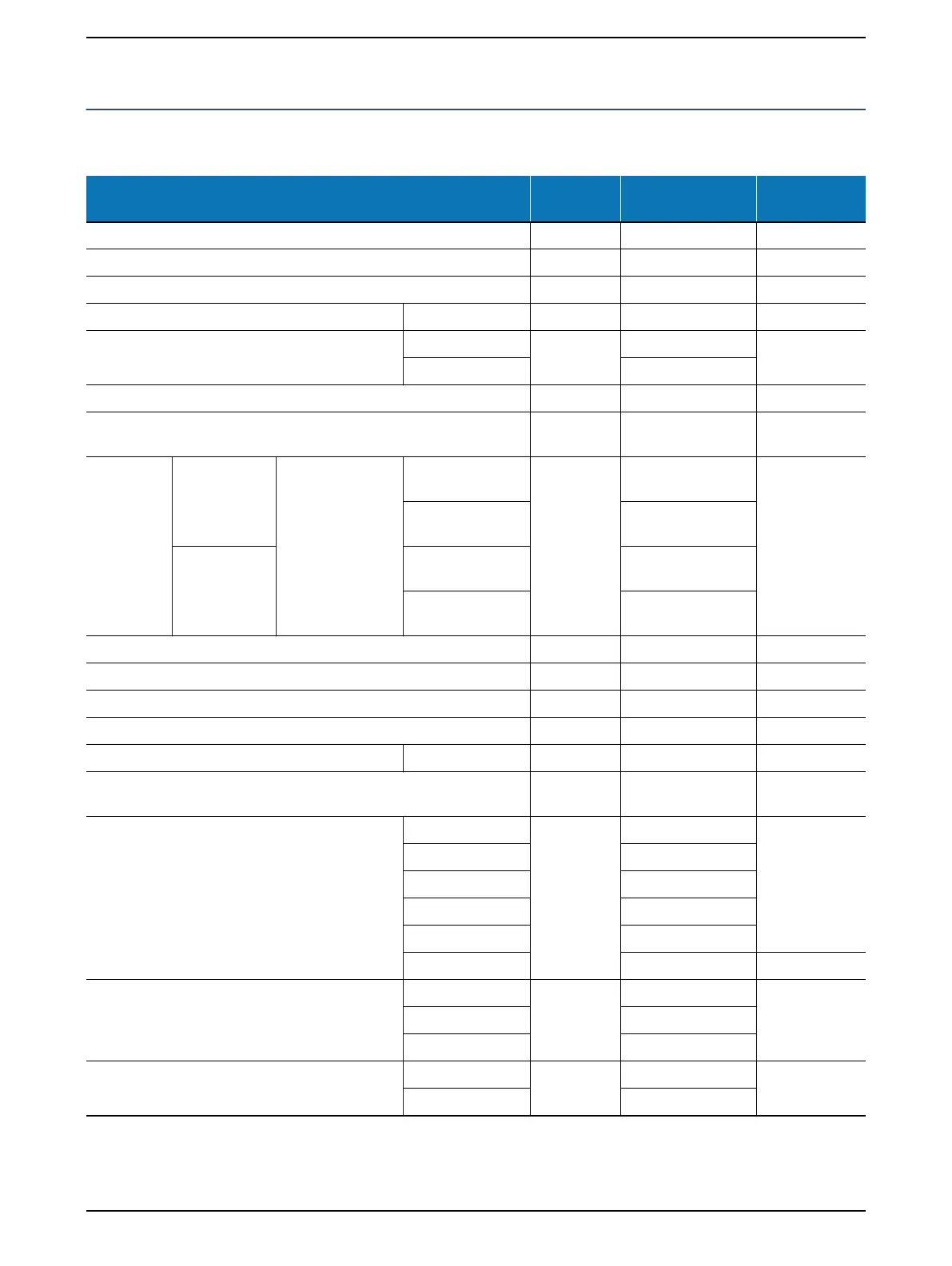

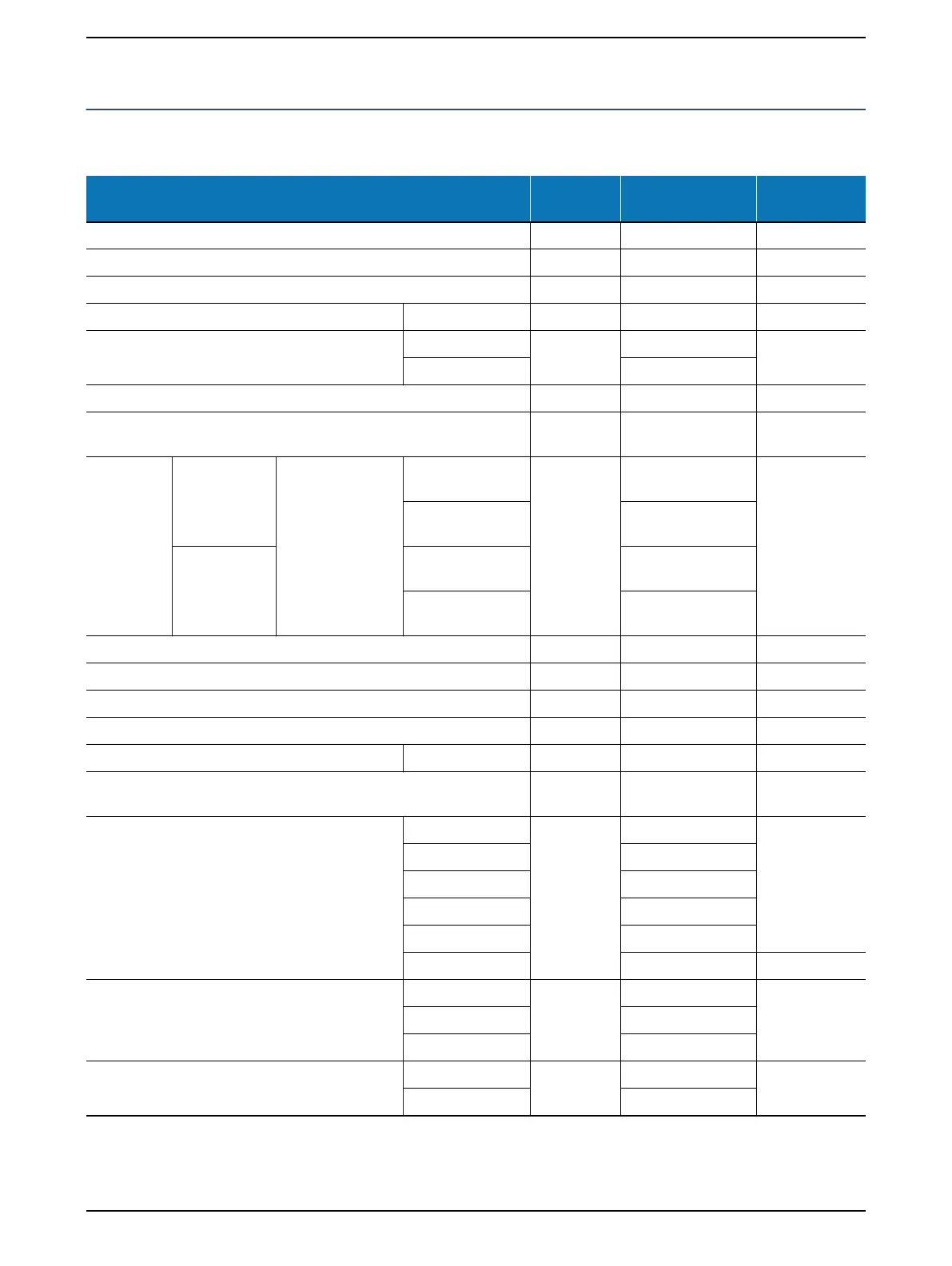

Engine Oil Quality Standards

*1: I test temp. (24°C [75°F] ), II test temp. (93.5°C [200°F]), III test temp. (24°C [75°F] after 93.5°C [200°F])

*2: Temperature of aluminum panel: 300°C [572°F] and 325°C [617°F], Temperature of engine oil: 100°C [212°F],

Splatter time: 15 seconds, Downtime: 45 seconds, Test time: 8 hours. The properties are the weight of solid product

accumulated on the panel.

Table 14-1 Engine Oil Quality Standards

Item Unit

Recommended

property value

Test method

API/JASO standards - CF grade -

SAE viscosity - 15W-40 -

ASTM Color - L4.0 JIS K 2580

Density 15°C [59°F] g/cm

3

0.87 to 0.90 JIS K 2249

Kinetic viscosity

40°C [104°F]

mm

2

/s

100 to 110

JIS K 2283

100°C [212°F] 13.5 to 15.5

Viscosity index - - JIS K 2283

Flash point °C [°F]

225 to 250

[437 to 482]

JIS K 2265

Base Num-

ber

Hydrochloric

acid method

Sulfur content in

fuel

1.0 weight% or

lower

mgKOH/g

10 or higher

(up to 13)

JIS K 2501

0.2 weight% or

lower

8 or higher

(up to 13)

Perchloric acid

method

1.0 weight% or

lower

13 or higher

(up to 16)

0.2 weight% or

lower

11 or higher

(up to 16)

Acid Number mgKOH/g 1.5 to 2.0 JIS K 2501

Sulfur content % 0.5 or lower JIS K 2541

Sulfuric acid ash % 2.0 or lower JIS K 2272

Carbon residue content % 2.0 or lower JIS K 2270

High temperature shear viscosity 150°C [302°F] mPa·S 3.7 or more JPI-5S-36-91

Pour point °C [°F]

-25 or lower

[-13 or lower]

JIS K 2269

Additives

Ca

Weight%

0.480 to 0.570

JIS K 0116

P 0.050 to 0.070

Zn 0.060 to 0.080

B-

Si 0.001 or lower

N 0.030 to 0.060 JIS K 2609

Bubbling test

*1

I

mL

10/0

JIS K 2518II 30/0

III 10/0

Panel coking test

*2

300°C [572°F]

mg

140 or lower

FED791-3462

325°C [617°F] 300 or lower

Loading...

Loading...