61, 65 and 70 Series Vertical Shaft Engines

40

Fuel tank vent

The fuel tank vent performs the important task of allow-

ing air into the fuel tank. As fuel is being used by the

engine, the fuel level in the tank drops. The dropping fuel

level then creates a vacuum in the tank. If the fuel tank

could not suck air through the vent, the vacuum would pre-

vent the fuel from getting to the carburetor.

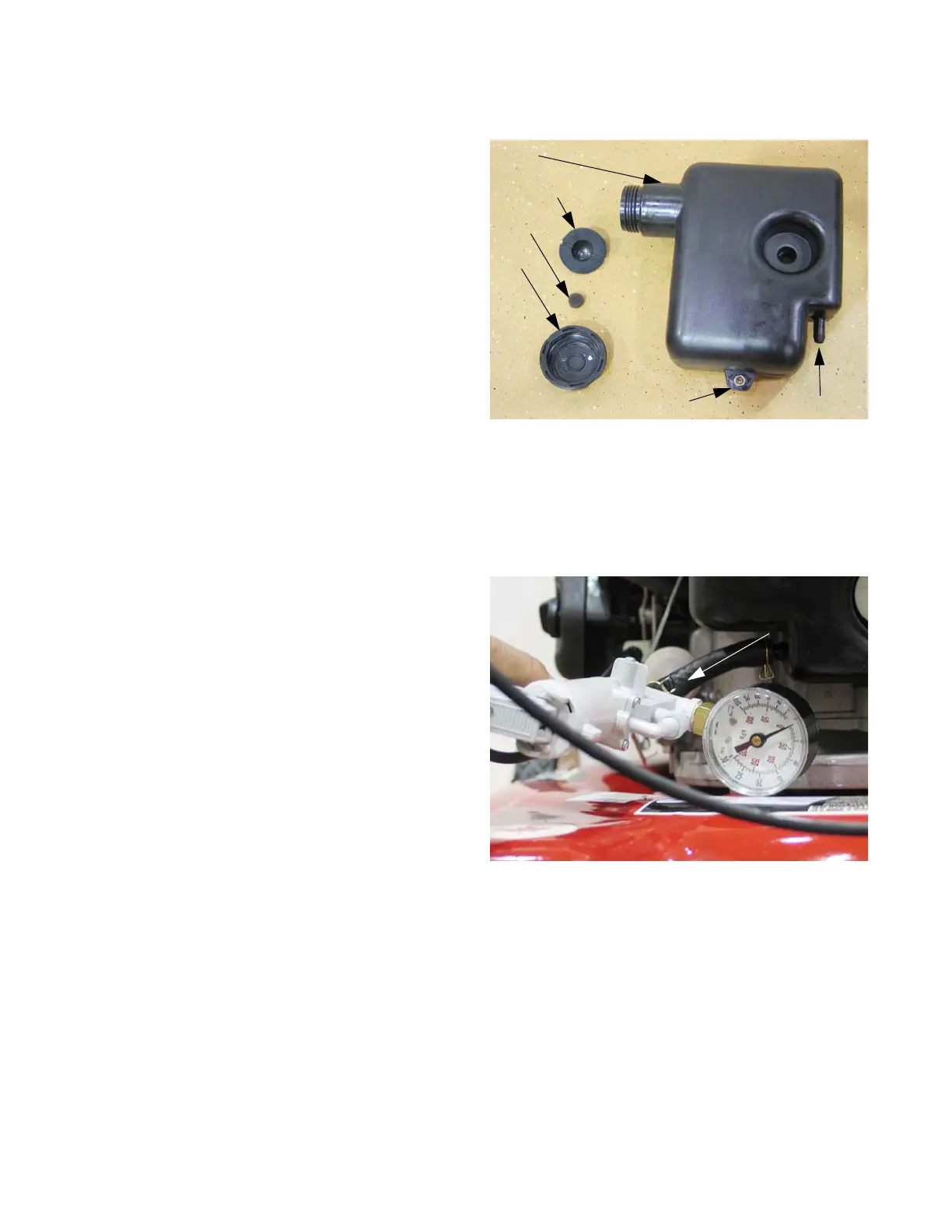

The tank is vented through the cap. See Figure 4.6.

To test the cap vent:

1. Drain the fuel out of the fuel tank into an approved

container.

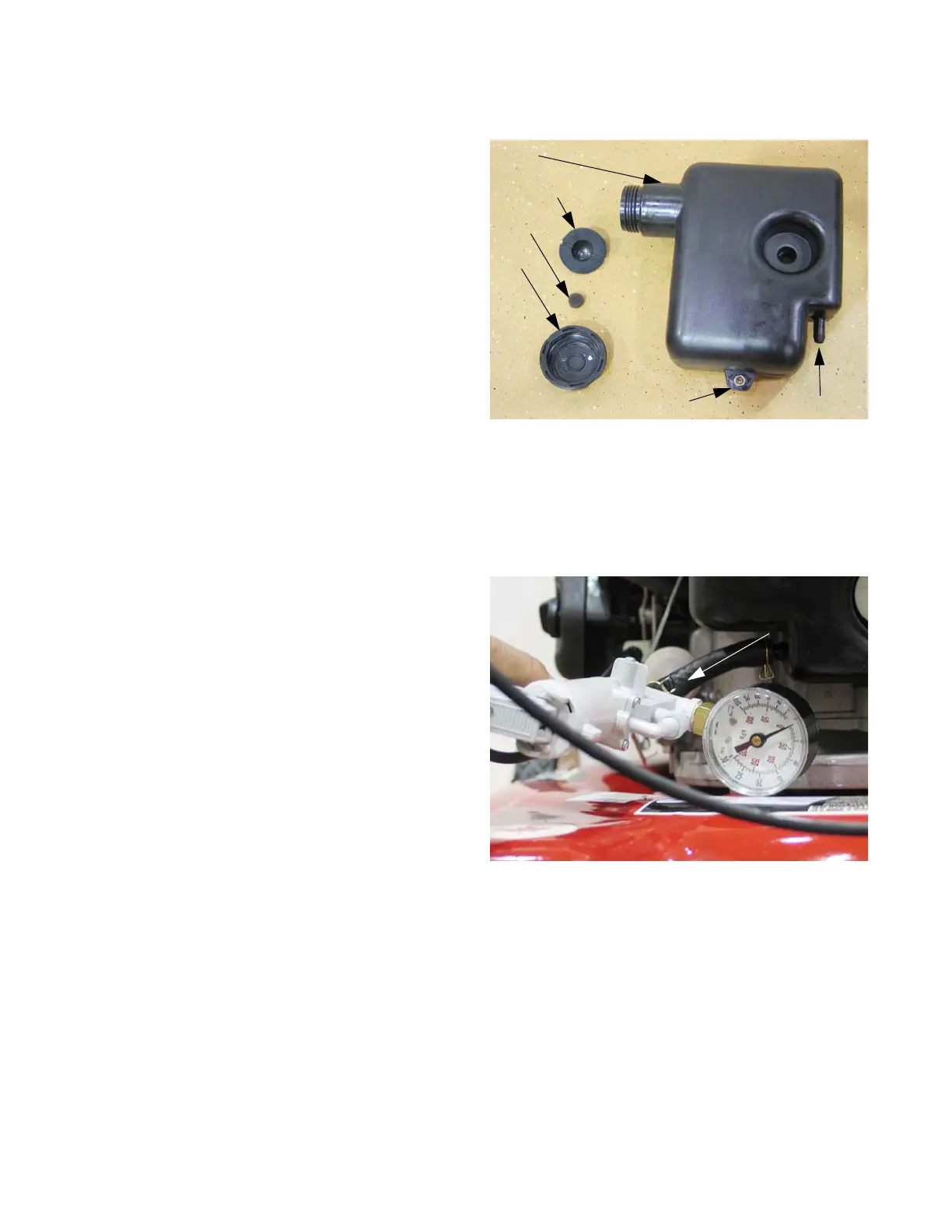

2. Attach a hand-pumped vacuum/pressure tester to

the fuel barb on the fuel tank. See Figure 4.7.

3. Attempt to pull a vacuum on the fuel tank with the

gas cap in place.

4. Attempt to pressurize the fuel tank with the gas cap

in place.

NOTE: The tank should not hold any pressure nor

any vacuum.

• Replace the cap if either pressure or vacuum

builds using the hand-pump tester.

• A cap that maintains pressure will cause the

engine to run rich as the fuel in the tank heats

and expands, forcing it’s way past the float

valve in the carburetor.

• A cap that maintains vacuum will cause the

engine to run lean as the fuel is depleted and

no air comes in to replace it.

• The two conditions may both be present, but

the symptoms vary with fuel, fuel level, and

operating conditions.

• Usually presents as a “Runs and quits” sce-

nario.

Figure 4.6

Tank

Cap liner / gasket

Filter

Cap

Sleeve (mtg. hole) Hose barb

Figure 4.7

Hand-pump vacuum

/ pressure tester

connected to fuel line

Loading...

Loading...