25Installing the System Piping

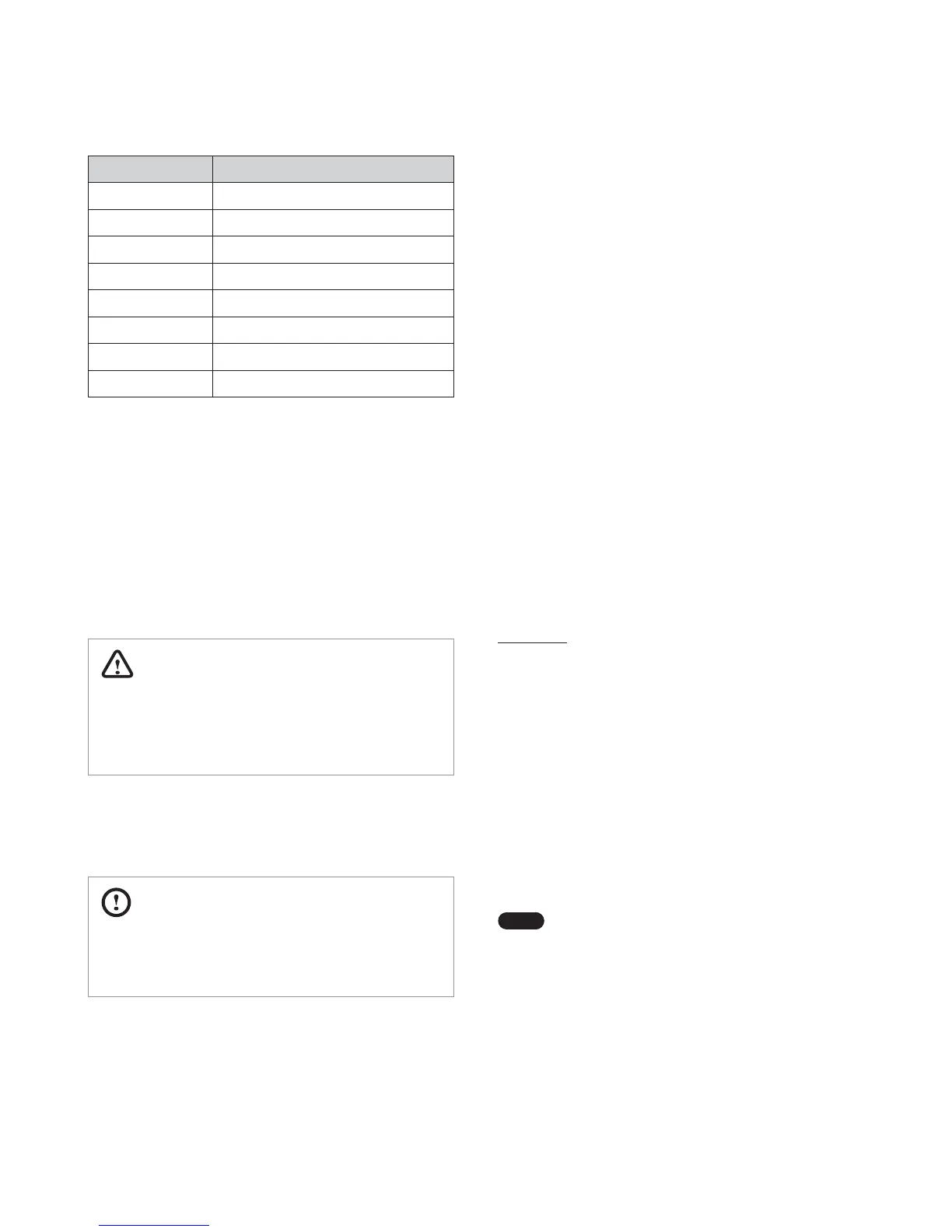

Contaminant Maximum Allowable Level

Total Hardness 200 mg/l (12 grains/gallon)

Aluminum 0.05 to 0.2 mg/l

Chloride 250 mg/l

Copper 1.0 mg/l

Iron 0.3 mg/l

Manganese 0.05 mg/l

pH 6.5-8.5

Sulfate 205 mg/l

2. Close the manual and automatic air vents and the boiler drain

valve.

3. Fill the boiler to the correct system pressure. The correct

pressure will vary with each application. The typical cold water

fill pressure for a residential system is 12 psi. The pressure

will rise when the boiler is turned on and the system water

temperature increases. The operating pressure must never

exceed the relief valve pressure setting.

4. At initial fill and during boiler start-up and testing, check

the system thoroughly for leaks. Repair any leaks before

proceeding further.

WARNING

Eliminate all system leaks. The continual introduction of fresh

makeup water will reduce boiler life. Minerals can build up in

the heat exchanger, reducing heat transfer, overheating the

heat exchanger and causing heat exchanger failure.

The system may have residual substances that could affect water

chemistry. After the system has been filled and leak tested,

verify that water pH and chlorine concentrations are within the

acceptable range by performing sample testing.

CAUTION

Before operating the boiler for the first time, ensure that the

boiler system is filled with water. Purge the air inside the

system to avoid damage to the boiler.

3.5 Examples of System Applications

Refer to the following examples to properly implement a system

for space heating, DHW supply, or both. These examples are

provided to suggest basic guidelines when you install the boiler

system. However, the actual installation may vary depending on

the circumstances, local building codes, or state regulations. Check

the local building codes and state regulations thoroughly before

installation, and comply with them fully.

3.5.1 Considerations for System Applications

Read and follow the guidelines listed below when installing system

piping for the Navien NHB boiler:

System application drawings are intended to explain the system

piping concept only.

When installing a mixing valve on the DHW piping, ensure that

the cold water pressure does not exceed the hot water pressure.

For the upstream side of all pumps, use straight pipes with a

minimum inside diameter of

1

/

2

in (12 mm).

Provide a system expansion tank following the guidelines on

page 18.

Installations must comply with all local codes. In Massachusetts,

a vacuum relief valve must be installed in the cold water line per

248 CMR.

Air Removal

The boiler and system plumbing layout must be configured to

promote the removal of air from the water. Air vents and bleeders

must be strategically placed throughout the system to aid in

purging the air from the system during commissioning of the

boiler. The system must also employ the use of a strategically

located air removal device, such as an air scoop or an air eliminator

designed to remove the air from the water as it flows through the

system.

Follow the installation instructions included with the air removal

device when placing it in the system; air removal devices generally

work better when placed higher in the system. Always locate air

removal devices in areas of the system that have a guaranteed

positive pressure, e.g., in close proximity to the water fill and

expansion tank.

Note

Connecting an air vent on top of the boiler is

recommended.

Loading...

Loading...