48 Setting the DIP Switches

CAUTION

Do not remove the front cover unless the power to the

boiler is turned off or disconnected. Failure to do so may

result in electric shock.

The boiler has 2 sets of DIP switches on the main circuit board

(PCB) and 2 sets of DIP switches on the front panel. DIP switches

are used to control the functionality of the boiler. Set the DIP

switches appropriately, based on the installation environment.

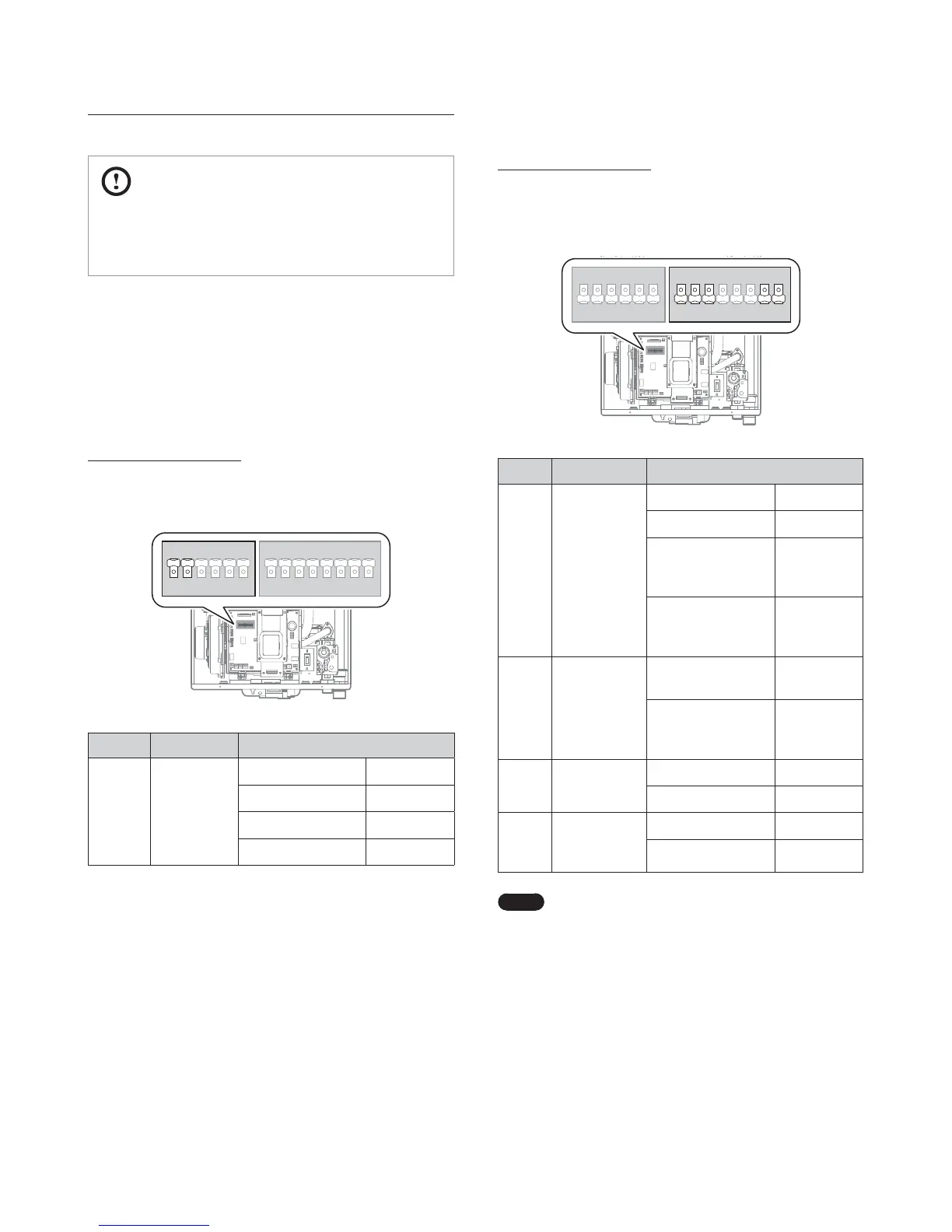

6.1 PCB DIP Switches

DIP Switch 1 (6 switch unit)

The DIP SW 1 on the circuit board configures the operation status

and model/capacity settings.

1 2 3 4 5 6

ON

1 2 3 4 5 6 7 8

ON

Switch Function Setting

1 & 2

Operation

Status

Normal Operation 1-OFF, 2-OFF

2-stage MAX 1-ON, 2-OFF

1-stage MIN 1-OFF, 2-ON

1-stage MAX 1-ON, 2-ON

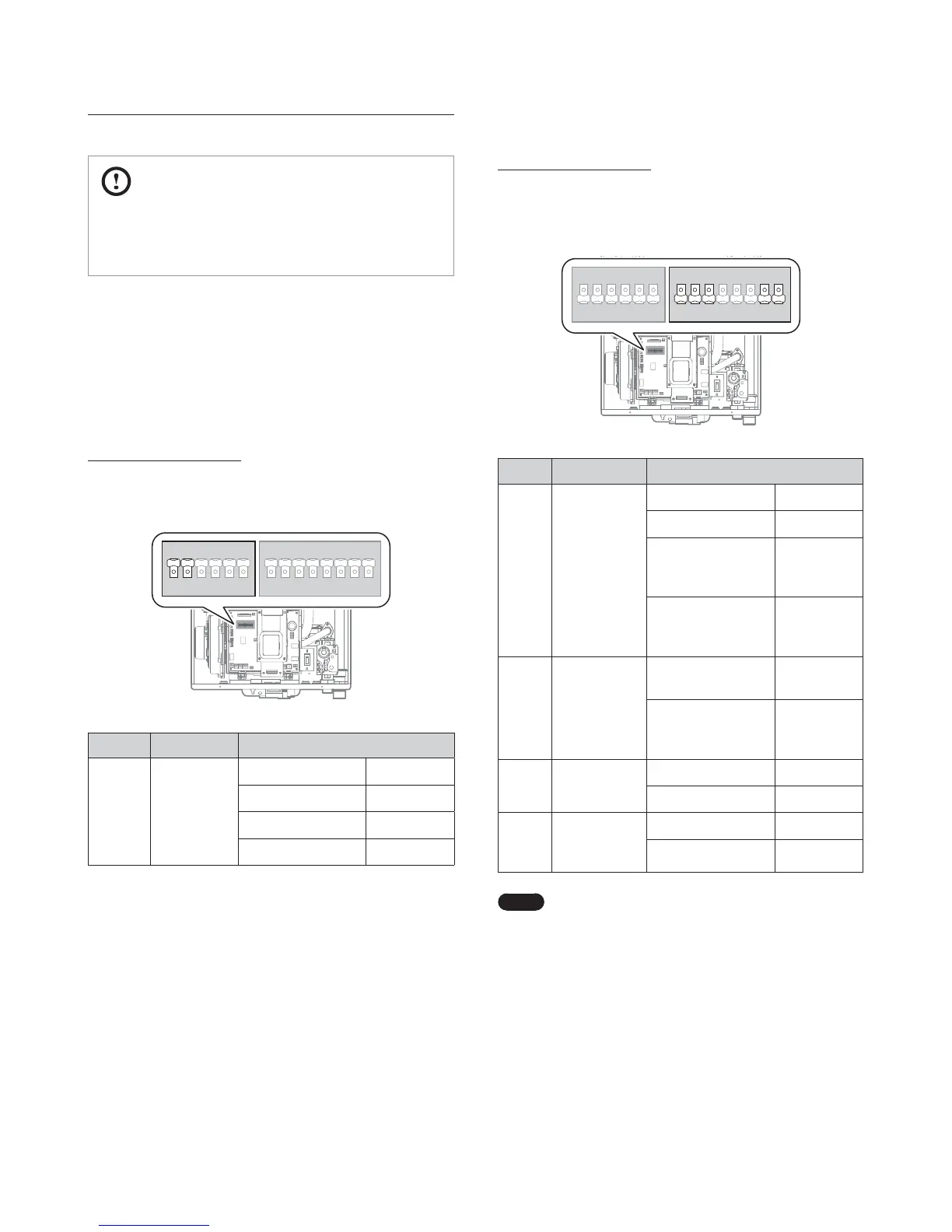

Dip Switch 2 (8 switch unit)

The DIP SW 2 on the circuit board configures the temperature

control modes, country, and enables or disables the space heating

thermostat.

1 2 3 4 5 6

ON

1 2 3 4 5 6 7 8

ON

Switch Function Setting

1 & 2

Space Heating

Temperature

Control

Supply Temperature 1-OFF, 2-OFF

Return Temperature 1-ON, 2-OFF

System Supply

Temperature (with

optional sensor)

1-OFF, 2-ON

System Return

Temperature (with

optional sensor)

1-ON, 2-ON

3

DHW Tank

Temperature

Control

DHW Supply

Temperature

3-OFF

DHW System Supply

Temperature (with

optional sensor)

3-ON

7

Space Heating

Thermostat

Used 7-OFF

Unused 7-ON

8

Exhaust

Temperature

Control

Used 8-OFF

Unused 8-ON

Note

When PCB DIP switch 2 #8 is set to On, ensure that

CPVC piping is used for exhaust venting.

6. Setting the DIP Switches

Loading...

Loading...