55Installing a Cascade System

8.1.1 Piping Sizes and Considerations

When plumbing a cascade system, consider the following pipe

diameters and flow rates. Note that flow rates above 4 ft/s may

cause pipe erosion or velocity noise. These specifications may vary

depending on installation conditions.

NHB-110

Qty

Flow Rate (GPM)

@ 20°F T

Recommended

Boiler Pipe Sizes (2-4 ft/s)

2 20.4 1- 1/2"

3 30.6 2"

4 40.8 2"

5 51 2- 1/2"

6 61.2 2- 1/2"

7 71.4 3"

8 81.6 3"

9 91.8 3- 1/2"

10 102 3- 1/2"

11 112.2 3- 1/2"

12 122.4 3- 1/2"

13 132.6 4"

14 142.8 4"

15 153 4"

16 163.2 4"

NHB-150

Qty

Flow Rate (GPM)

@ 20°F T

Recommended

Boiler Pipe Sizes (2-4 ft/s)

2 27.6 2"

3 41.4 2"

4 55.2 2- 1/2"

569 3"

6 82.8 3"

7 96.6 3- 1/2"

8 110.4 3- 1/2"

9 124.2 3- 1/2"

10 138 4"

11 151.8 4"

12 165.6 4"

13 179.4 5"

14 193.2 5"

15 207 5"

16 220.8 5"

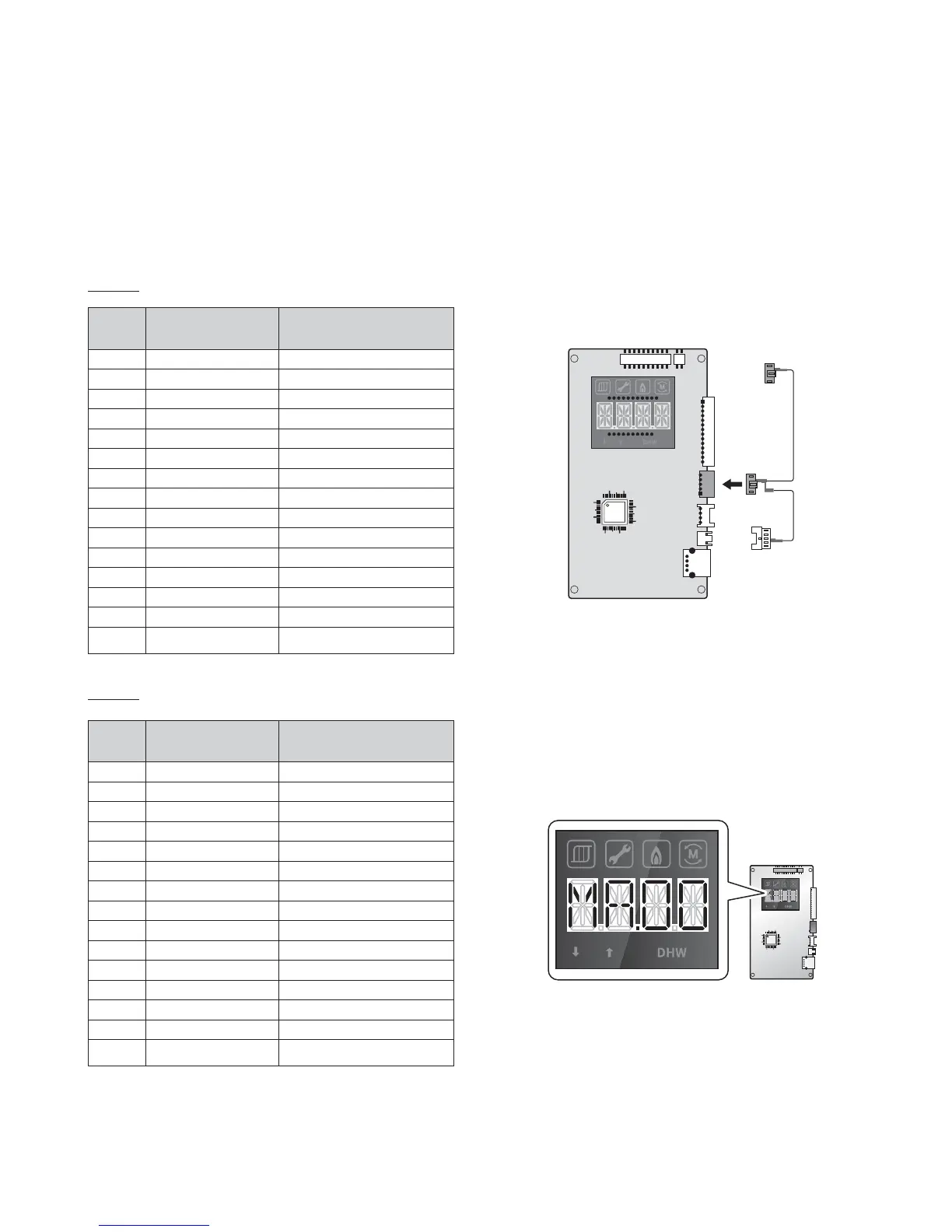

8.2 Connecting the Communication Cables

Up to 16 boilers can be connected with Navien Ready-Link

communication cables. Select one of the boilers in the cascade

system as the master boiler, and then connect the other boilers to

it as slaves. Before making any connections, ensure that the power

is turned off to all boilers.

Connect the Ready-Link cables to the J6 ports on the right side of

the front panel:

psi

O/R

S

R

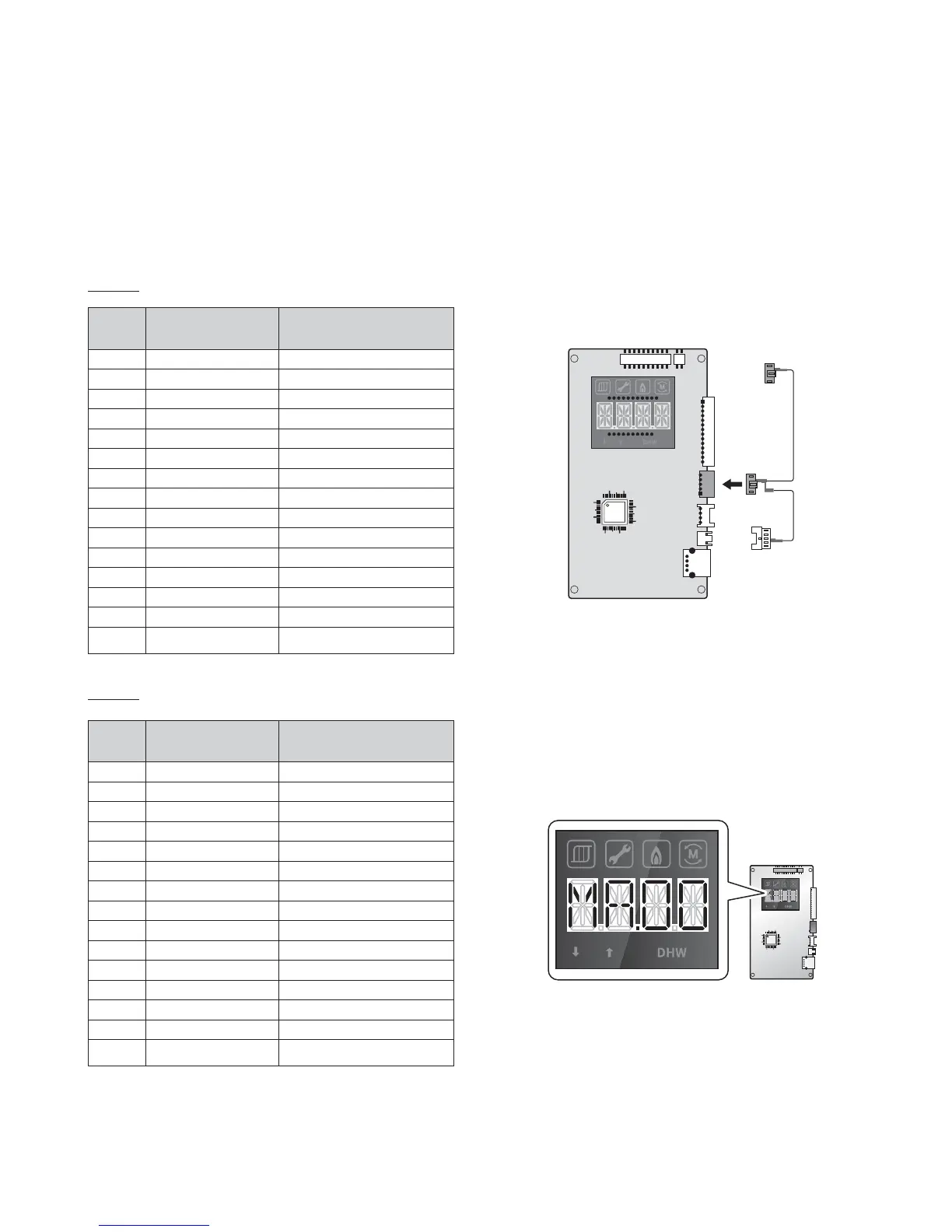

8.2.1 Configuring the Communication Settings

After connecting the Ready-Link communication cables, restore

power to the boiler and turn on all boilers using the Power button.

To configure the communication settings:

1. On the master boiler, press and hold the Diagnostic and Up(+)

buttons for more than 5seconds. “MA.00” will appear on the

display to confirm that this boiler is set as the master.

psi

O/R

S

R

psi

O/R

S

R

Loading...

Loading...