GEO M12 HARDWARE SETUP PROCEDURE Page 65/90

IMPORTANT

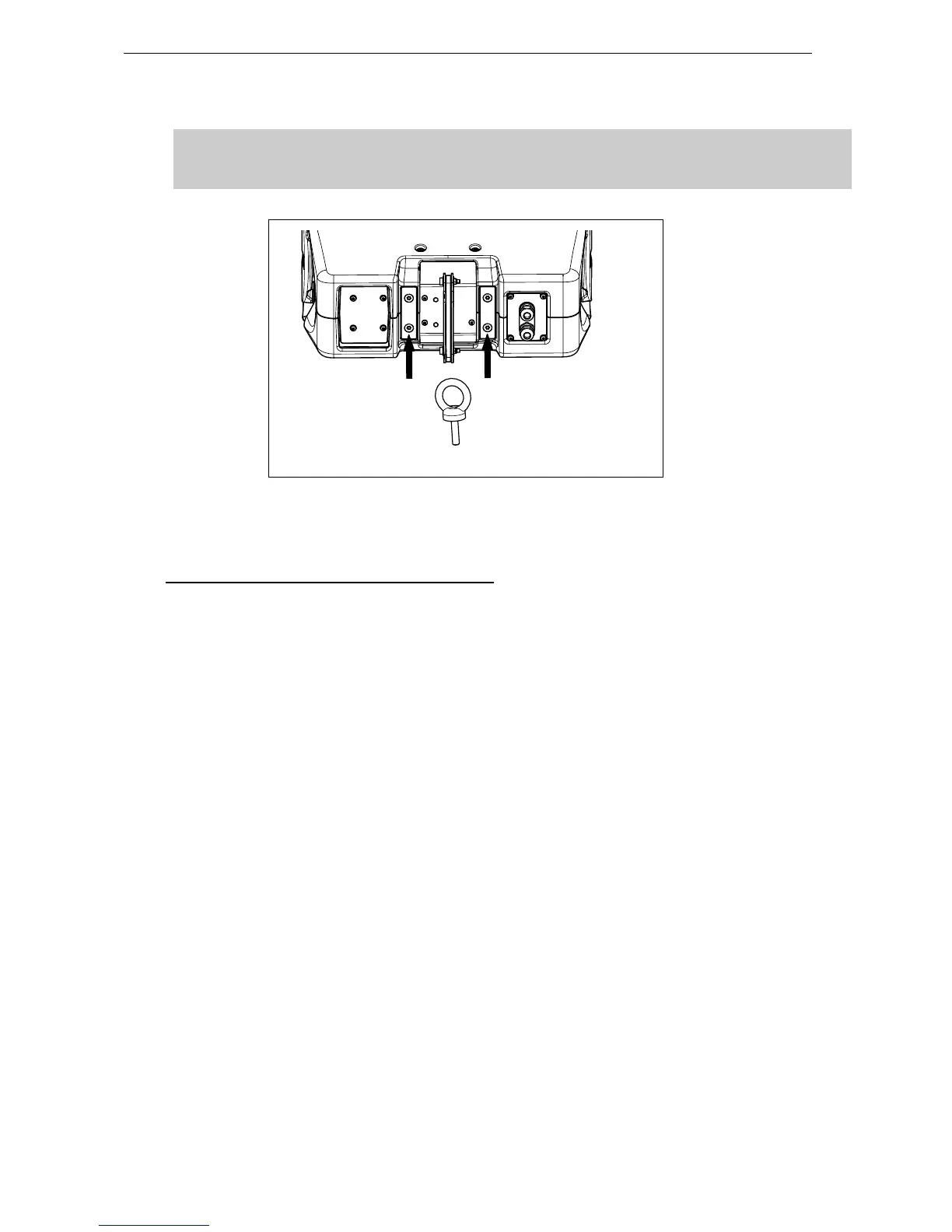

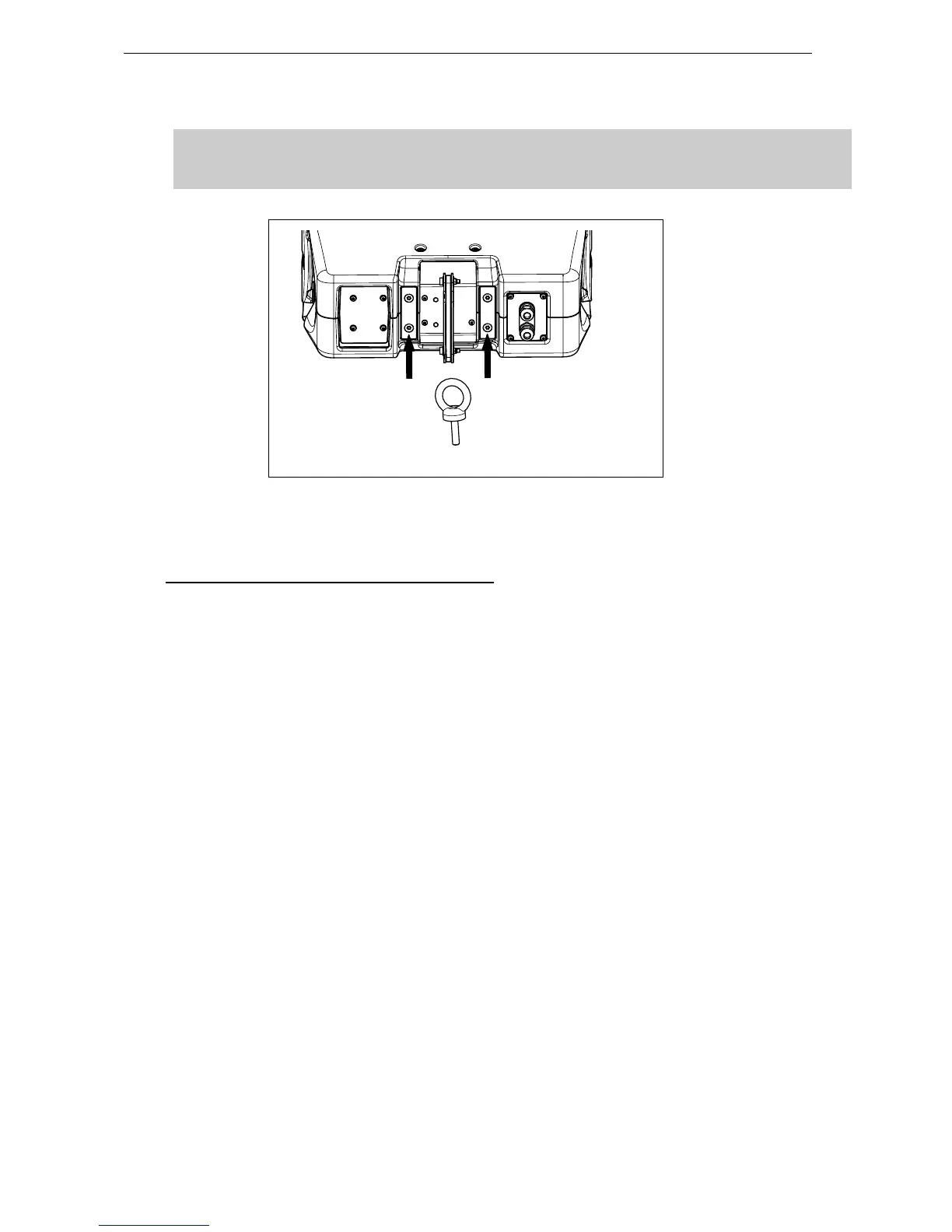

Any of the four screws securing the rear rigging plate can be replaced with an eyebolt

(M8), connected to sling (apply thread lock on the eyebolt).

6.6 Testing and Maintenance of the system

General: GEO is a precision piece of equipment and requires regular attention to maintenance in order

to give long and reliable service. NEXO recommends regular testing of loudspeaker rigging components,

preferably using a suitable test rig coupled with a visual inspection.

Fasteners: there are several critical points in the MSUB18 and GEO M12 cabinets.

Of primary concern are:

a) The screws or magnets attaching the grid to the cabinet

b) The machine screws attaching the connecting plates to the cabinet.

c) The magnets attaching the directivity flanges to the front of the cabinet.

These fasteners should be regularly checked and tightened as necessary.

Cleaning: The exterior of the cabinet and the rigging system can be cleaned with a damp cloth soaked in

mild soapy water. On no account use solvent based cleaners, which may damage the finish of the cabinet

After cleaning, the rigging system must be treated with a suitable lubricant to prevent rusting. NEXO

recommends the use of Scottoil FS365 which is a water-based lubricant with a mixture of machine oil,

surfactant and anti-rust treatment.

Loading...

Loading...