2

EN

before resetting it.

• Theautomationmechanismcannotbeusedbeforeithasbeencommis-

sionedasspeciedinthechapteron“Testingandcommissioning”.

• Inspecttheautomationmechanismfrequentlytocheckforunbalancing,

signs of wear or damage to electrical cables and mechanical parts. Do not

use the automation mechanism if adjustment or repair is required.

• If it is not used for a long time, remove the optional battery and keep it in a dry

place to make sure it does not leak harmful substances.

• Thepackingmaterialsoftheproductmustbedisposedofincompliancewith

local regulations.

1.3 - Warnings about use

• Theproductisnotintendedforusebypersons,includingchildren,withlim-

ited physical, sensory or mental capacities, or who lack experience or knowl-

edge, unless supervised or trained in the use of the product by a person

responsible for their safety.

• Anychildrenneartheautomationsystemmustbekeptundersupervisionto

ensure that they do not play with it.

• Donotallowchildrentoplaywiththexedcontroldevices.Keepremote

control devices out of their reach as well.

• Cleanthesurfacesoftheproductwithasoft,slightlydampcloth.Useonly

water; do not use cleaning products or solvents.

2

PRODUCT DESCRIPTION AND INTENDED USE

This product is intended to be used to automate sliding gates used in residential

premises. CAUTION!–Allusesotherthantheintendedusedescribed

anduseinenvironmentalconditionsotherthanthosedescribedinthis

manualshouldbeconsideredimproperandforbidden!

RUN is a line of one-way electromechanical gearmotors with electronic control-

ler and SM type connector for the wireless receiver (optional). Electrical con-

nectionswithexternaldevicesaresimpliedthankstouseofthe“BlueBus”,a

technique permitting connection of multiple devices with only 2 wires. The list

of devices compatible with RUN over the BlueBus network is given in Chap-

ter7.3.1“BlueBus”;anup-to-datelist,withcompatibilityspecications,isalso

available on www.niceforyou.com.

RUN has a remote programmer connector to facilitate installation, maintenance

and troubleshooting; see Chapter 7.8.1 “Remote programmer”.

Ifmainspowered,Runcanbettedwithabackupbatterytoprovidepower

during power failures so that it can be operated for several hours (see par.

7.8.2). In the event of power failure, it is still possible to operate the gate by

releasing the gearmotor with its release handle (see par. 3.6).

The automation mechanism permits installation of various accessories to add

functions and improve security.

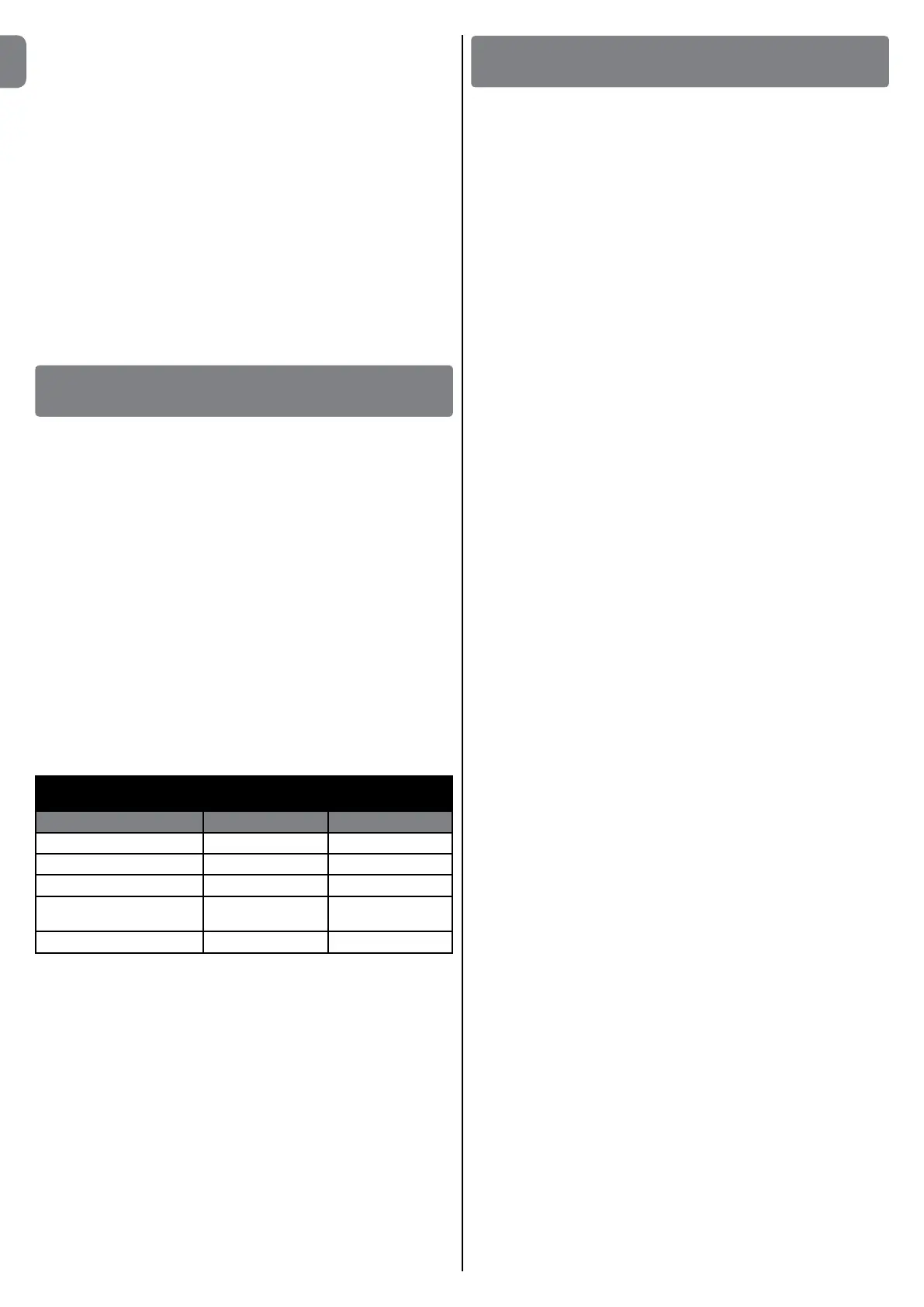

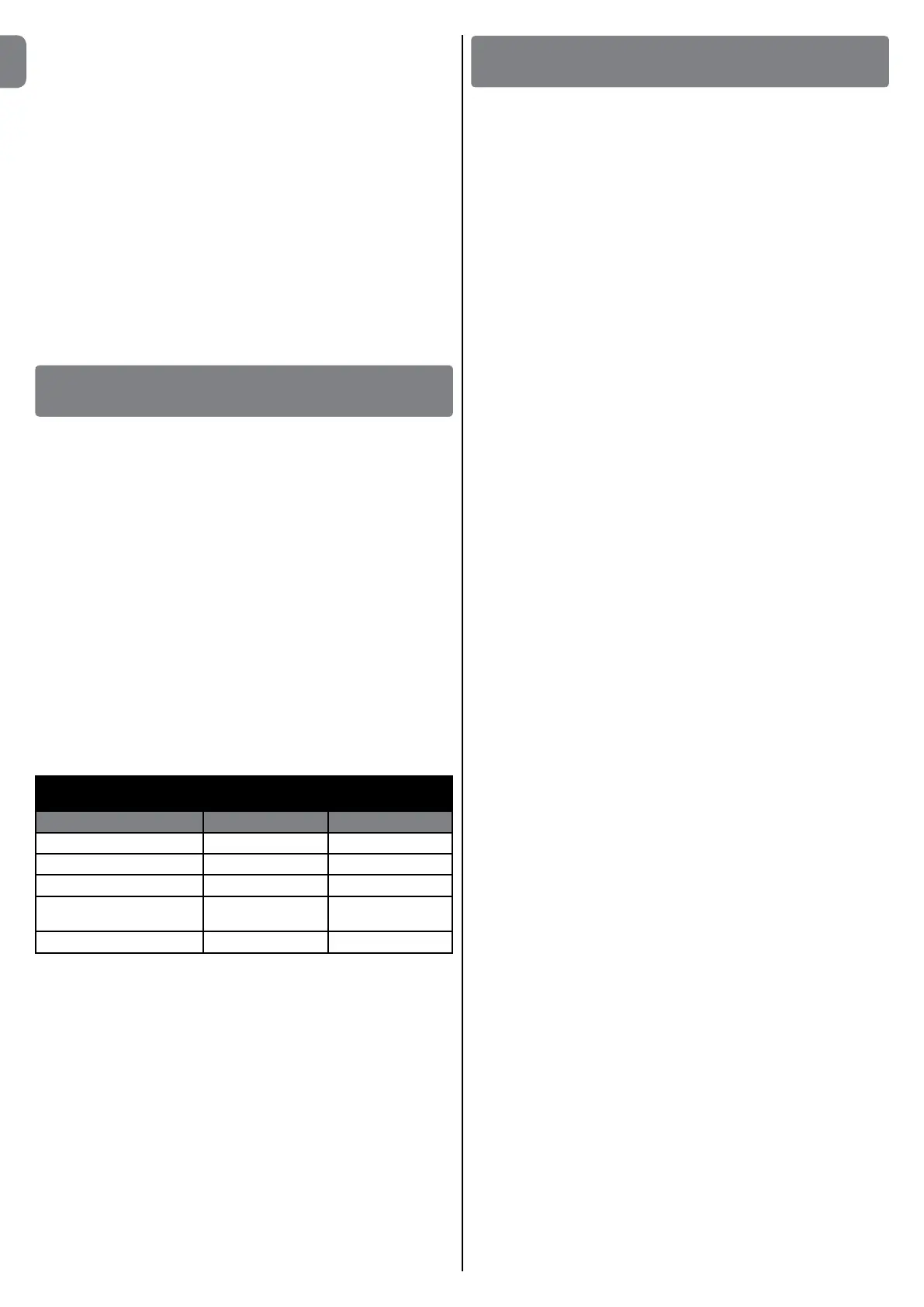

TheRUNproductlineincludesthefollowingproducts(table1-seeg.1).

TABLE 1

comparison of basic characteristics of RUN gearmotors

Gearmotor type RUN400HS RUN1200HS

Type of limit switch electromechanical electromechanical

Max. gate length 14 mt 14 mt

Max. gate weight 300 kg 1200 kg

Maximum startup torque

(corresponding to force)

14.7Nm

(409N)

28.4Nm

(790N)

Motor 24V; 5500RPM 24V; 3100RPM

Note: 1kg = 9.81N, so that, for instance: 1390N = 142 kg

3

INSTALLATION

3.1 - Tests prior to installation

Caution!-TheinstallationofRUNmustbecarriedoutbyqualifiedper-

sonnelincompliancewithcurrentlegislation,standardsandregula-

tions,andthedirectionsprovidedinthismanual.

Before proceeding with the installation of RUN you must:

• Checkthatallthematerialsareinexcellentcondition,suitableforuseand

that they conform to the standards currently in force.

• Makesurethatthestructureofthegateissuitableforautomation.

• Makesurethattheweightanddimensionsofthegatefallwithinthespecified

operating limits provided in chapter 3.2 “Operating limits”.

• Checkthattheforcerequiredtostartthemovementofthegateislessthan

half the “maximum torque”, and that the force required to keep the gate in

movement is less than half the “nominal torque”. Compare the resulting val-

ues with those specified in the “Technical Characteristics”. The manufacturer

recommends a 50% margin on the force, as unfavourable climatic conditions

may cause an increase in the friction.

• Makesurethattherearenopointsofgreaterfrictionintheopeningorclosing

phases of the gates.

• Checkthatthereisnoriskofderailmentorthatthegatesmaycomeofftheir

guides.

• Makesurethatthemechanicalstopsaresturdyenoughandthatthereisno

risk of deformation even if the gate hits the mechanical stop violently.

• Makesurethatthegatesectionisbalanced,i.e.itmustnotmoveifleftstillin

any position.

• Makesurethattheareawherethegearmotorisfixedisnotsubjecttoflood-

ing; iff necessary, mount the gearmotor raised from the ground.

• Makesurethattheinstallationareaenablesthereleaseofthegearmotorand

that it is safe and easy to release it manually.

• Makesurethatthemountingpositionsofthevariousdevicesareprotected

from impacts and that the mounting surfaces are sufficiently sturdy.

• Componentsmustneverbeimmersedinwaterorotherliquids.

• KeepRUNawayfromheatsourcesandopenflames;inacid,salineorpoten-

tially explosive atmosphere; this could damage RUN and cause malfunctions

or dangerous situations.

• Ifthereisanaccessdoorinthegate,orwithintherangeofmovementofthe

gate, make sure that it does not obstruct normal travel and, if necessary,

provide an appropriate interlock system.

• Connectthecontrolunittoanelectricitysupplywithasafetyearthsystem.

• Connectthegatetotheprotectiveearthinaccordancewithcurrentlegisla-

tion.

• Provideadeviceontheelectricitysupplylinethatensurescompletedis-

connection of the automation mechanism from the grid. The disconnection

device must have contacts with an opening distance large enough to per-

mit complete disconnection under the conditions sanctioned by overvoltage

category III, in accordance with installation regulations. The device ensures

quick, safe disconnection from the power supply if needed, and must there-

fore be positioned in view of the automation mechanism. If, on the other

hand, it is located in a position which is not visible, there must be a system

forpreventingaccidentalorunauthorizedreconnectionwiththepowergridto

prevent this risk. The disconnection device is not supplied with the product.

3.2 - Operating limits

The “Technical Characteristics” chapter provides all the data needed to deter-

mine whether the products of the RUN line are suitable for the intended appli-

cation.

The structural characteristics of RUN make it suitable for use on sliding gates in

conformity with the limits indicated in tables 2 and 3.

The effective suitability of RUN to automate a particular sliding gate depends on

the friction as well as other correlated factors, such as ice, that could interfere

with the movement of the gate.

For an effective control it is absolutely vital to measure the force necessary

to move the gate throughout its entire run and ensure that this is less than

half of the “nominal torque” indicated in chapter 8 “Technical characteristics” (a

50% margin on the force is recommended, as unfavourable climatic conditions

may cause an increase in the friction); furthermore, it is necessary to take into

consideration the data indicated in tables 1 and 2 to establish the number of

cycles/hour, consecutive cycles and maximum speed allowed.

Loading...

Loading...