3

EN

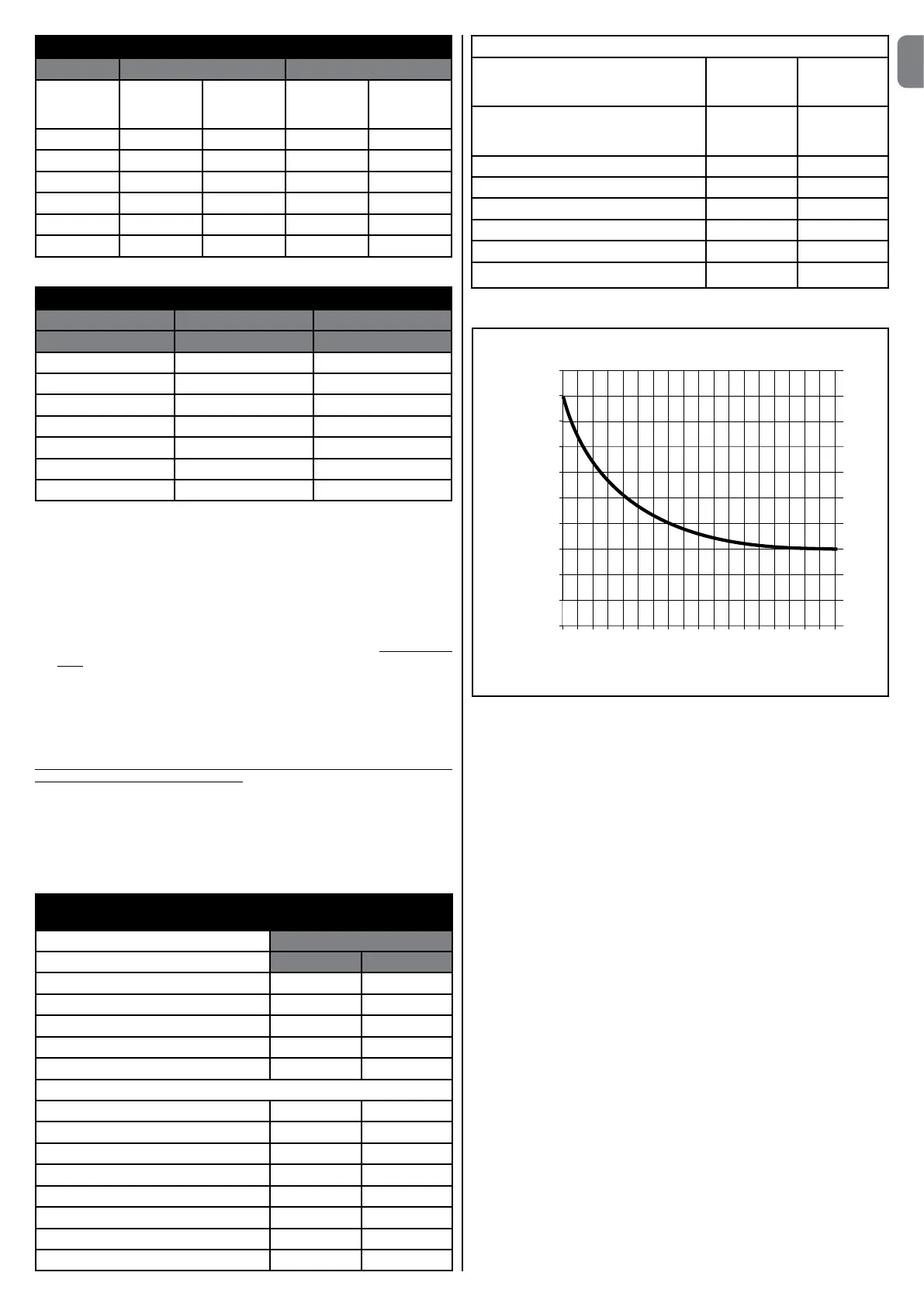

TABLE 2 - Limits in relation to the length of the gate

RUN1500

RUN1200HS

Leave

width(m)

Max. no.

of cycles/

hour

Max. no. of

consecu-

tive cycles

Max. no.

of cycles/

hour

Max. no. of

consecu-

tive cycles

Up to 4 67 33 36 21

4 ÷ 6 45 26 26 15

6 ÷ 8 37 21 23 12

8 ÷ 10 29 18 17 10

10 ÷ 12 25 15 14 8

12 ÷ 14 22 13 13 7

TABLE 3 - Limits in relation to the weight of the gate

RUN1500

RUN1200HS

Gate weight (kg) % cycles % cycles

50 ÷ 100 100% 100%

100 ÷ 200

90

80

200 ÷ 300

80

75

300 ÷ 550

75

60

550 ÷ 800

60

50

800 ÷ 1000

50

40

1000 ÷ 1200

40

30

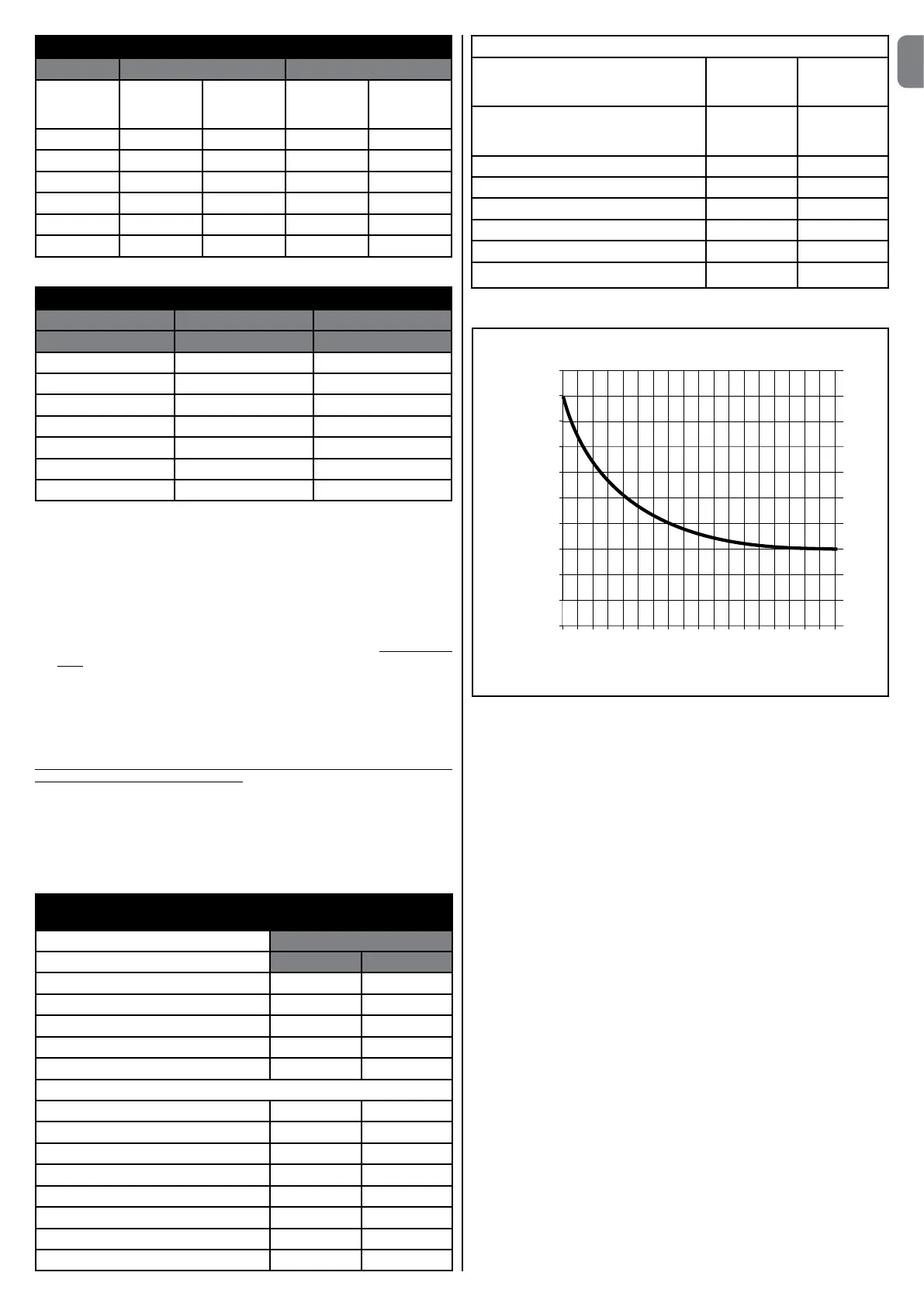

3.2.1-Productdurability

Durability is the average economic life span of the product. The value of the life

spanisstronglyinuencedbytheintensityofthemanoeuvres,i.e.thesumofall

factors that contribute to product wear, see Table 4.

To estimate the life span of your automated device, proceed as follows:

01. Add the values of the items in Table 4 regarding the system conditions;

02. In Graph 1 from the value obtained above, trace a vertical line until it inter-

sectsthecurve;fromthispointtraceahorizontallineuntilitintersectsthe

line of the “manoeuvre cycles”. The obtained value is the estimated life

span of your product.

Thelifetimevaluesspeciedinthegraphareonlyobtainableifthemaintenance

schedule is strictly observed (see chapter “Maintenance schedule”). The esti-

mation of durability is made on the basis of design calculations and the results

of tests performed on prototypes. As it is only an estimation, it does not repre-

sent any form of guarantee on the effective life span of the product.

Sample durability calculation: automation of a gate with a door 10 m long with a

weight of 150 Kg, installed near the sea:

Table 4 shows the “severity index” for this type of installation: 15% (length of gate), 30%

(weight of gate) and 10% (ambient temperature > 40°C or < 0°C or humidity > 80%”).

These indicators must be added together to obtain the overall severity index, which is

in this case 55%. With the value identied (55%), look at the horizontal axis of Graph

1 (“severity index”), and identify the value corresponding to the number of “manoeuvre

cycles” our product will be able to perform in its life span, about 180,000 cycles.

TABLE4-Estimateddurabilityinrelation

tothecycleseverityindex

Severityindex% Run

1500

1200HS

Gate length m

Up to 6 5% 5%

6 ÷ 9 10% 10%

9 ÷ 12 15% 15%

12 ÷ 14 20% 20%

Gate weight (kg)

50 ÷ 100 10% 5%

100 ÷ 200 30% 10%

200 ÷ 300 60% 20%

300 ÷ 550 30%

550 ÷ 800 40%

800 ÷ 100 50%

100 ÷ 1200 60%

Other fatigue factors (to be considered

if the probability of occurrence is greater

than 10%)

Surrounding temperature greater than

40°C or lower than 0°C or humidity

greater than 80%

10% 10%

Presence of dust and sand 15% 15%

Presence of salinity 20% 20%

Operation interrupted by photocell 10% 10%

Operation interrupted by Stop 20% 20%

Active peak force 10% 10%

Totalseverityindex%:

GRAPH 1

Severityindex%

Durability in cycles

0

50.000

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

100.000

150.000

200.000

250.000

300.000

350.000

400.000

450.000

500.000

3.3 - Works in preparation for installation

g.2 provides an example of an automation system, produced using Nice

components:

1 Key switch

2 FT210B receiver

3 Photocells

4 FT210B transmitter

5 Main mobile edge

6 Open stop bracket

7 Rack

8 Flasher with integral antenna

9 RUN

10 Closed stop bracket

11 Secondary mobile edge (optional)

12 Transmitter

These parts are positioned according to a typical standard layout. With refer-

encetog.2,locatetheapproximatepositionforinstallationofeachcom-

ponent envisaged in the system. Important – Before installation, prepare the

electric cables required for the system, with reference to g.2 and to “Table

5-Technicalspecicationsofelectriccables”.

Caution - When laying the ducting for routing the electrical cables, also take

into account that due to possible deposits of water in the routing ducts, the

connection pipelines might create condensate in the control unit, with conse-

quent damage to the electronic circuits.

30%

40%

50%

60%

Loading...

Loading...